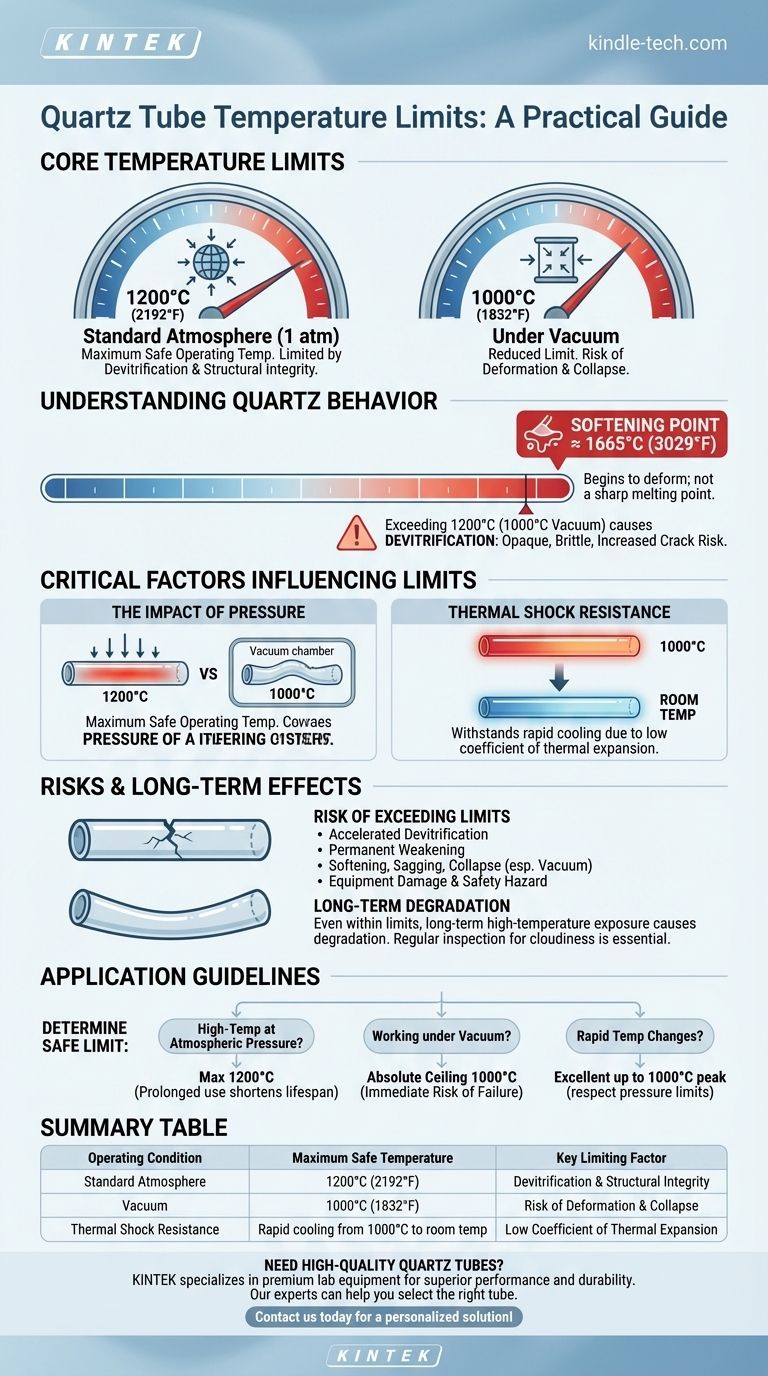

The maximum operating temperature for a standard quartz tube is typically around 1200°C (2192°F) when used at standard atmospheric pressure. This value is not absolute, as the effective temperature limit is highly dependent on the operational environment. Critically, when used under vacuum conditions, this limit is reduced to approximately 1000°C (1832°F).

A quartz tube's temperature rating is not a single number but a function of its working conditions. Its practical upper limit is dictated by factors like pressure, duration of exposure, and the risk of material degradation, not just its theoretical melting point.

Why a Single Temperature Isn't the Full Story

While we often look for a single number, the behavior of quartz at high temperatures is complex. Understanding the different thermal points of the material is crucial for using it safely and preventing premature failure.

The True Melting Point

Fused quartz does not have a sharp, defined melting point like crystalline materials. Instead, it has a softening point around 1665°C (3029°F), where it begins to deform under its own weight. This is far higher than its practical use limit.

Practical Operating Limits

The recommended maximum of 1200°C is a practical guideline for continuous use. Above this temperature, a process called devitrification can occur. The amorphous glass structure of the quartz slowly begins to crystallize, making it opaque, brittle, and far more susceptible to cracking upon cooling.

Critical Factors That Define the Real-World Limit

The official temperature rating of a quartz tube is always influenced by the specific application. Two factors are paramount.

The Impact of Pressure

Pressure is the most significant variable. At standard atmospheric pressure (1 atm), a quartz tube maintains its structural integrity up to 1200°C.

Under a vacuum, the lack of external pressure makes the tube more vulnerable to deformation and collapse at high temperatures. For this reason, the maximum safe operating temperature is reduced to 1000°C.

Thermal Shock Resistance

One of the greatest strengths of quartz is its extremely low coefficient of thermal expansion. This gives it exceptional thermal shock resistance.

A quartz tube can withstand a rapid temperature drop from as high as 1000°C down to room temperature without fracturing. This makes it ideal for applications involving rapid heating and cooling cycles.

Understanding the Trade-offs

Pushing a quartz tube beyond its recommended limits introduces significant risk and is rarely worth the potential outcome.

The Risk of Exceeding the Limit

Operating above 1200°C (or 1000°C under vacuum) dramatically increases the rate of devitrification. This permanently weakens the tube.

More immediately, the tube will begin to soften and can sag, deform, or even collapse, especially under vacuum. This can destroy your equipment, ruin your experiment, and create a serious safety hazard.

Long-Term Degradation

Even when operating within the prescribed limits, long-term exposure to high temperatures will eventually cause the quartz to degrade. Regular inspection of the tube for signs of cloudiness (crystallization) or deformation is essential for safe operation.

How to Determine the Safe Limit for Your Application

Use these guidelines to select the right operating parameters for your goal.

- If your primary focus is high-temperature processing at atmospheric pressure: You can safely operate up to 1200°C, but be mindful that prolonged use near this limit will shorten the tube's lifespan.

- If your primary focus is working under a vacuum: Your absolute ceiling is 1000°C. Exceeding this poses an immediate risk of structural failure.

- If your primary focus involves rapid temperature changes: Quartz is an excellent choice. You can perform rapid cooling from up to 1000°C without damage, provided the peak temperature respects the pressure limitations.

Respecting these operational boundaries is the key to leveraging the unique properties of quartz both safely and effectively.

Summary Table:

| Operating Condition | Maximum Safe Temperature | Key Limiting Factor |

|---|---|---|

| Standard Atmosphere | 1200°C (2192°F) | Devitrification & Structural Integrity |

| Vacuum | 1000°C (1832°F) | Risk of Deformation & Collapse |

| Thermal Shock Resistance | Rapid cooling from 1000°C to room temp | Low Coefficient of Thermal Expansion |

Need a high-quality quartz tube tailored for your specific temperature and pressure requirements? KINTEK specializes in premium lab equipment and consumables, offering quartz tubes designed for superior performance and durability in demanding laboratory environments. Our experts can help you select the right tube to ensure safety and efficiency in your high-temperature applications. Contact us today to discuss your needs and get a personalized solution!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Multi-zone Laboratory Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the purpose of using an agate mortar for LDIP processing? Master Precision in Oil-Water Separation Membranes

- What measures should be taken to prevent cross-contamination when using different sizes of alumina powder?

- Why are zirconia milling jars preferred as reaction vessels for sulfide solid electrolyte powders? Ensure High Purity

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.

- Why are tungsten carbide-cobalt (WC–Co) grinding jars and balls used for high-hardness ceramics? Superior Wear Resistance

- What are the advantages of high-purity quartz reaction tubes compared to metal? Ensure Data Integrity in Lab Research

- What is the purpose of the vacuum pump? A Key Tool for Controlling Process Environments

- What is the function of combining an ultrasonic disperser and a mechanical stirrer? Achieve Flawless Slurry Dispersion