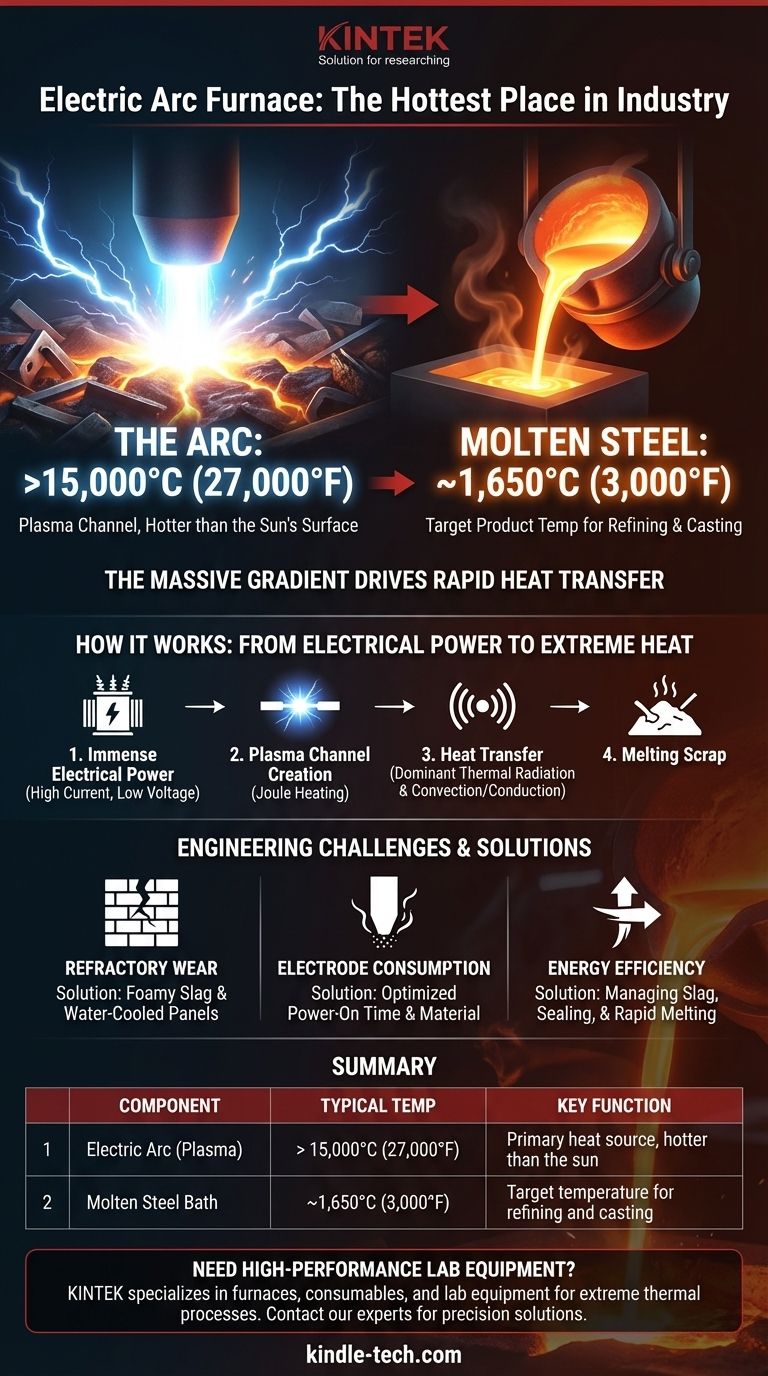

The temperature of the electric arc itself is staggering. The arc in an Electric Arc Furnace (EAF) is a plasma channel that can reach temperatures exceeding 15,000°C (27,000°F). This is significantly hotter than the surface of the sun, which is around 5,500°C, making it one of the hottest environments used in any major industry.

The core challenge in an Electric Arc Furnace isn't merely achieving high temperatures, but precisely controlling an astronomically hot plasma arc to efficiently transfer its energy into the steel scrap without destroying the furnace itself.

Arc vs. Steel: A Critical Distinction

To understand the EAF process, you must differentiate between the temperature of the arc and the temperature of the molten steel it is creating. The massive difference between these two values is the entire key to the furnace's operation.

The Arc Temperature (~15,000°C / 27,000°F)

This is the temperature of the plasma column itself. When a massive electrical current jumps the gap between the graphite electrode and the metal scrap, it ionizes the surrounding gas, creating a channel of superheated matter.

This extreme temperature is a localized phenomenon, existing only within the arc's immediate path.

The Molten Steel Bath Temperature (~1,650°C / 3,000°F)

This is the target temperature of the actual product—the liquid steel. The steel needs to be hot enough for refining processes and for casting into its next form.

This temperature is carefully controlled and monitored throughout the process to ensure the final steel has the desired chemical properties and quality.

Why the Massive Temperature Gradient Matters

The enormous difference between the arc and the steel is what drives incredibly rapid and efficient heat transfer.

According to the laws of thermodynamics, heat flows from a hotter body to a colder one. The greater the temperature difference (the gradient), the faster that heat will flow. The EAF leverages this principle to melt tons of cold steel scrap in a remarkably short amount of time.

How This Extreme Heat is Generated and Transferred

The creation of the arc is a brute-force application of electrical engineering principles. The goal is to convert electrical energy into thermal energy as efficiently as possible.

Immense Electrical Power

An EAF uses very large graphite electrodes, which are lowered into a furnace filled with scrap metal. A powerful transformer delivers high-current, low-voltage power to these electrodes.

Creating the Plasma Channel

An arc is initiated between the electrode tips and the scrap metal. The intense electrical energy strips electrons from the atoms in the air, creating a stable, high-resistance channel of plasma that glows brilliantly.

It is the electrical resistance of this plasma that generates the intense heat, a principle known as Joule heating.

The Dominance of Thermal Radiation

The primary mechanism for heat transfer in an EAF is thermal radiation. The arc acts like a miniature sun inside the furnace, radiating immense thermal energy in all directions.

This radiation blasts the solid scrap, heating it past its melting point. Convection within the hot gases and direct conduction from where the arc physically touches the metal also contribute, but radiation does the vast majority of the work.

Understanding the Engineering Challenges of Extreme Heat

Operating a device hotter than the sun's surface presents significant material science and engineering challenges. The entire furnace is designed to manage and contain this destructive power.

Refractory Wear

The inner lining of the furnace is made of special heat-resistant bricks called refractories. The intense radiation from the arc constantly degrades this lining, which must be regularly repaired and replaced.

Operators use techniques like creating a "foamy slag" layer to partially shield the furnace walls from the arc's direct radiation, extending the life of the refractories.

Electrode Consumption

The tips of the graphite electrodes are at the heart of the plasma and slowly vaporize from the extreme heat. Electrodes are a major consumable cost in EAF operations, and managing their consumption rate is a key skill.

Energy and Thermal Efficiency

While the process is fast, a significant amount of energy is lost. The furnace walls are lined with water-cooled panels to prevent them from melting, which continuously carries heat away from the process.

Optimizing the "power-on" time, managing the foamy slag, and ensuring a good seal on the furnace are all critical for maximizing thermal efficiency.

Making the Right Choice for Your Goal

Your understanding of the arc's temperature can be applied differently depending on your objective.

- If your primary focus is understanding the core physics: Recognize that the EAF harnesses a controlled plasma channel hotter than the sun's surface to do its work.

- If your primary focus is operational reality: The central task is managing the destructive power of the arc to protect the furnace lining and electrodes while maximizing heat transfer to the steel.

- If your primary focus is process efficiency: The immense temperature difference between the arc and the scrap is the key driver that makes the EAF a rapid and effective melting technology.

Ultimately, the electric arc furnace is a testament to controlling one of the most extreme states of matter on Earth for industrial production.

Summary Table:

| Component | Typical Temperature | Key Function |

|---|---|---|

| Electric Arc (Plasma) | > 15,000°C (27,000°F) | Primary heat source, hotter than the sun's surface |

| Molten Steel Bath | ~1,650°C (3,000°F) | Target temperature for refining and casting |

Need high-performance lab equipment to study extreme thermal processes? KINTEK specializes in furnaces, consumables, and lab equipment designed for demanding applications. Whether your research involves high-temperature materials or process optimization, our solutions are built for precision and durability. Contact our experts today via our contact form to find the right equipment for your laboratory's needs.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What temperature does steel liquify? Understanding the Melting Range for Your Applications

- What are the 4 types of heat treatment steel undergoes? Master Annealing, Normalizing, Hardening & Tempering

- How does heat affect strength materials? The Science of Thermal Degradation Explained

- How should the products and waste liquid be handled after an experiment? Ensure Lab Safety and Compliance

- Why the melting temperature of ceramic is higher than for most metals? Unpacking Atomic Bond Strength