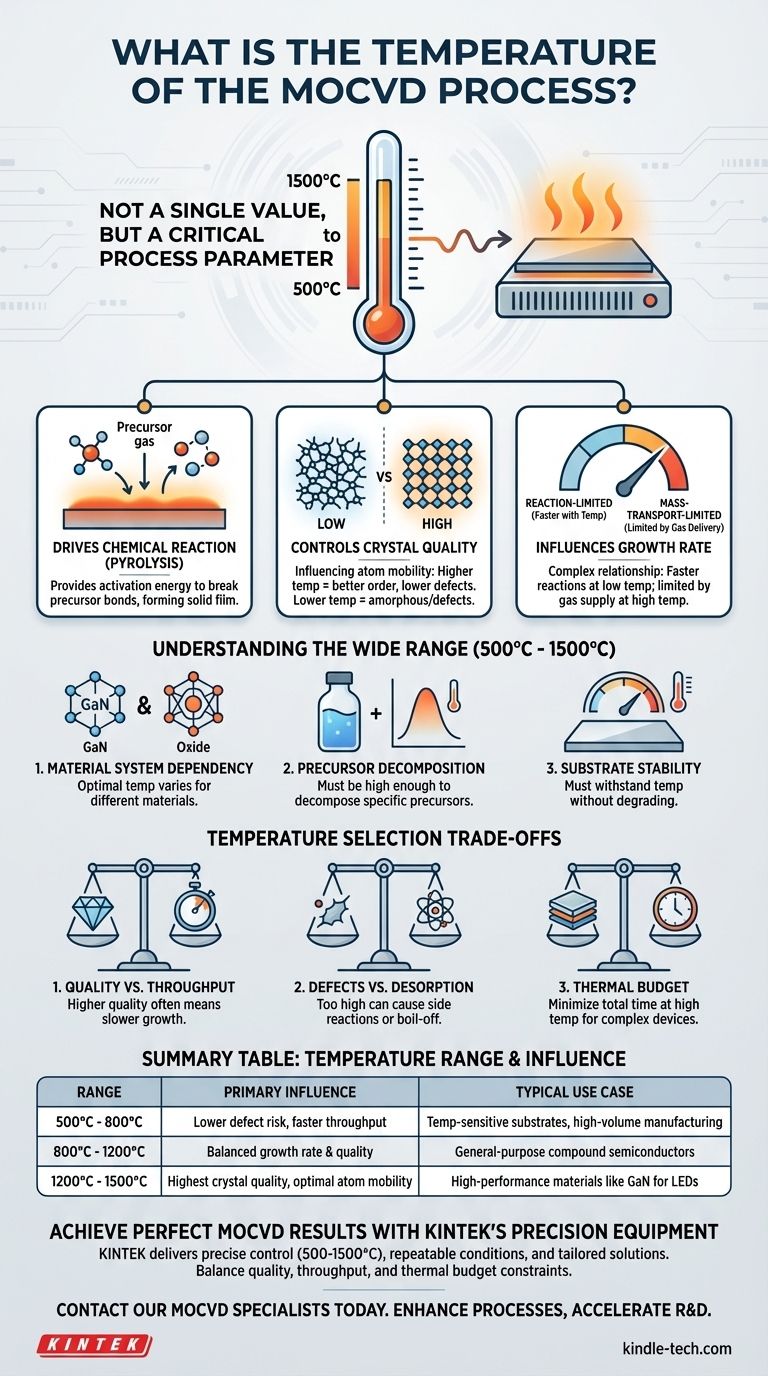

In MOCVD, temperature is not a single value but a critical process parameter. The process is typically performed by heating the substrate to a temperature between 500 and 1500 degrees Celsius. This heat is essential to provide the energy needed for the gaseous precursor chemicals to decompose and react on the substrate surface, forming the desired solid film.

The core takeaway is that temperature directly controls the chemical reactions, crystal quality, and growth rate of the deposited film. The wide operating range exists because the optimal temperature is not universal; it is highly dependent on the specific material being grown and the desired properties of the final product.

The Role of Substrate Temperature in MOCVD

Temperature is arguably the most important variable in the MOCVD process. It doesn't just "heat things up"; it orchestrates the entire film growth at a molecular level.

Driving the Chemical Reaction

The foundational purpose of heat in MOCVD is to initiate pyrolysis, the thermal decomposition of the metal-organic precursor molecules.

The substrate is heated to provide the necessary activation energy. This breaks the chemical bonds in the precursor gases, allowing the constituent atoms to become available for forming the solid film.

Controlling Crystal Structure and Quality

The temperature of the substrate directly influences the mobility of atoms once they land on the surface.

Higher temperatures give atoms more energy to move around and find their ideal, low-energy positions within a crystal lattice. This leads to a more ordered, higher-quality crystalline film.

Conversely, if the temperature is too low, atoms are "frozen" in place shortly after they arrive. This can result in a disordered, amorphous, or poorly crystalline material with more defects.

Influencing the Film Growth Rate

Temperature has a direct and complex relationship with the rate at which the film grows.

In a reaction-limited regime, typically at lower temperatures, the growth rate increases with temperature because the chemical reactions happen faster.

However, at higher temperatures, the process can enter a mass-transport-limited regime. Here, the reaction is so fast that the growth rate is limited only by how quickly precursor gases can be delivered to the substrate surface.

Understanding the Wide Temperature Range (500°C to 1500°C)

The vast temperature window for MOCVD is not arbitrary. It reflects the diverse materials and chemical systems the technique is used for.

Dependency on the Material System

Different materials require vastly different thermal conditions for optimal growth.

Growing Gallium Nitride (GaN) for LEDs, for example, occurs at very different temperatures than growing a simple oxide film. The ideal temperature is dictated by the chemical and physical properties of the target material.

Precursor Decomposition Point

The chosen temperature must be high enough to efficiently decompose the specific metal-organic precursors being used.

Modern liquid precursors, which are safer than older compounds, have their own unique decomposition profiles that influence the required process temperature.

Substrate Stability

The substrate itself must be able to withstand the chosen temperature without melting, degrading, or reacting undesirably with the growing film. This sets a practical upper limit on the process temperature.

Understanding the Trade-offs of Temperature Selection

Choosing a temperature is a balancing act. Optimizing for one property, like crystal quality, can negatively impact another, like production speed.

Quality vs. Throughput

Higher temperatures generally yield better crystal quality but may require more energy and lead to slower, more controlled growth.

Lowering the temperature might allow for faster deposition rates, increasing throughput, but often comes at the cost of reduced film quality and more defects.

Risk of Defects and Desorption

If the temperature is too high, it can be detrimental. It may cause unwanted side reactions, inter-diffusion between the film and substrate, or even cause atoms to "boil off" the surface (desorption) faster than they can be incorporated into the film.

Thermal Budget Constraints

In fabricating complex devices with many layers, the total time a device spends at high temperatures (the "thermal budget") is a critical concern.

Each high-temperature MOCVD step can affect previously deposited layers. Therefore, engineers often aim for the lowest possible temperature that still achieves the required material properties to preserve the integrity of the entire device.

Making the Right Choice for Your Goal

The ideal MOCVD temperature is determined by your specific material and performance goals. There is no single "best" temperature, only the right temperature for your application.

- If your primary focus is the highest possible crystal quality: You will likely operate toward the higher end of the valid temperature range for your material system to enhance atom mobility on the surface.

- If your primary focus is high-volume manufacturing (throughput): You may need to find a temperature that balances a fast growth rate with an acceptable, though not necessarily perfect, film quality.

- If your primary focus is working with temperature-sensitive substrates or existing layers: Your goal will be to find the lowest possible temperature that still achieves the necessary precursor decomposition and desired material properties.

Ultimately, mastering temperature control is fundamental to achieving precise and repeatable results in any MOCVD application.

Summary Table:

| Temperature Range | Primary Influence | Typical Use Case |

|---|---|---|

| 500°C - 800°C | Lower defect risk, faster throughput | Temperature-sensitive substrates, high-volume manufacturing |

| 800°C - 1200°C | Balanced growth rate and quality | General-purpose compound semiconductors |

| 1200°C - 1500°C | Highest crystal quality, optimal atom mobility | High-performance materials like GaN for LEDs and power devices |

Achieve Perfect MOCVD Results with KINTEK's Precision Equipment

Struggling to optimize your MOCVD temperature parameters for consistent film quality and growth rates? KINTEK specializes in advanced lab equipment and consumables for semiconductor research and production. Our MOCVD solutions deliver:

- Precise temperature control (500-1500°C) for optimal crystal structure

- Repeatable process conditions to minimize defects and maximize yield

- Tailored configurations for GaN, oxides, and other material systems

Whether you're developing next-generation LEDs, power electronics, or semiconductor devices, our expertise helps you balance quality, throughput, and thermal budget constraints.

Contact our MOCVD specialists today to discuss how we can enhance your thin-film deposition processes and accelerate your R&D or manufacturing timeline.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Molybdenum Vacuum Heat Treat Furnace

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings