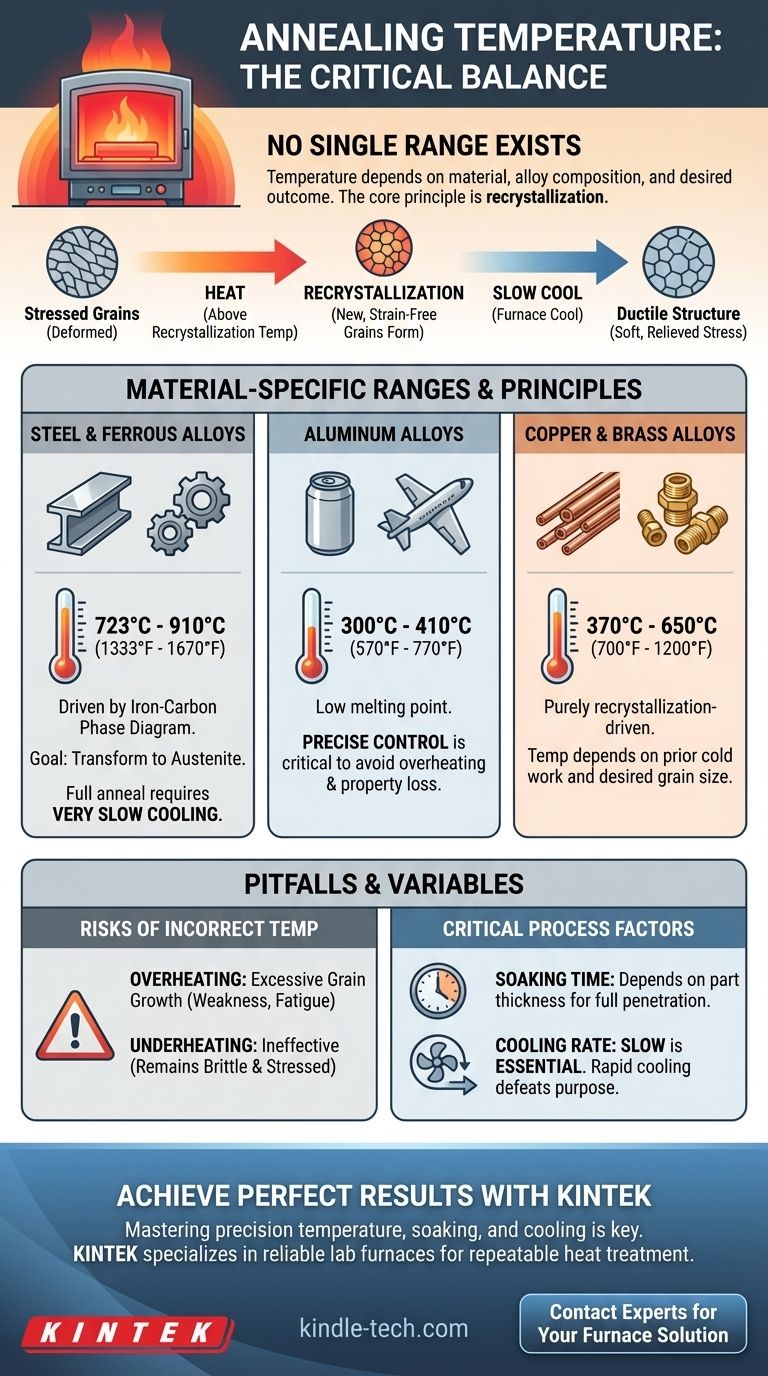

Crucially, there is no single temperature range for annealing. The correct temperature is entirely dependent on the specific material being heat-treated, its alloy composition, and the desired outcome. For steels, this typically falls between 723°C and 910°C (1333°F and 1670°F), while for aluminum alloys, it can be as low as 300°C to 410°C (570°F to 770°F).

The core principle of annealing is not about hitting a magic number, but about heating a material above its recrystallization temperature and then cooling it slowly. This process repairs the material's internal crystal structure, relieving stress and increasing its ductility.

The Core Principle: What Annealing Achieves

At a microscopic level, annealing is a process of recovery and repair. It reverses the effects of work-hardening, which occurs when a metal is bent, forged, or machined.

Relieving Internal Stresses

When you bend a piece of metal, you are not just changing its shape; you are deforming its internal crystal structure, known as grains. This creates a high density of defects called dislocations, which makes the material harder, more brittle, and full of internal stress.

The Role of Temperature

Heat provides the thermal energy necessary for atoms within the crystal lattice to move. As the temperature rises, this atomic mobility increases significantly.

Recrystallization: The Key Transformation

The most important event during annealing is recrystallization. This is the point at which new, strain-free grains begin to form and grow, consuming the old, deformed grains. For annealing to be effective, the temperature must be high enough to initiate and complete this process.

Why Temperature Varies by Material

The recrystallization temperature is a unique property of each material, which is why annealing temperatures differ so drastically.

Steel and Ferrous Alloys

For steel, annealing temperatures are precisely determined by the iron-carbon phase diagram. The goal is often to heat the steel above its upper critical temperature (A3 or Acm) to transform its structure into a uniform phase called austenite.

A full anneal for a typical carbon steel involves heating it to approximately 30-50°C (50-90°F) above this critical point, holding it there, and then cooling it extremely slowly in the furnace. This produces a soft, ductile, and coarse pearlite structure.

Copper and Brass Alloys

Copper and its alloys, like brass, do not undergo the same phase transformations as steel. Their annealing is purely about recrystallization.

The typical annealing temperature range for pure copper is 370°C to 650°C (700°F to 1200°F). The exact temperature depends on the amount of prior cold work and the desired final grain size.

Aluminum Alloys

Aluminum has a much lower melting point, so its annealing temperatures are also significantly lower. The range is generally between 300°C to 410°C (570°F to 770°F).

Controlling temperature is especially critical for aluminum, as overheating can easily lead to a loss of mechanical properties or even partial melting.

Understanding the Trade-offs and Pitfalls

Achieving the correct annealing result requires a precise balance of temperature, time, and cooling rate. Getting any of these wrong can ruin the workpiece.

The Risk of Overheating

Exceeding the optimal annealing temperature is dangerous. It can cause excessive grain growth, where the newly formed crystals become too large. This significantly reduces the material's strength, toughness, and fatigue life. In extreme cases, it can lead to permanent damage or melting.

The Problem of Underheating

If the temperature is too low—below the material's recrystallization point—the annealing process will simply fail. The internal stresses from work-hardening will not be relieved, and the material will remain hard and brittle.

The Influence of Soaking Time

Soaking refers to holding the material at the target temperature. The time required depends on the thickness and mass of the part. A thick component needs a longer soak time to ensure the heat penetrates fully to its core and the entire structure transforms.

The Critical Role of Cooling Rate

For most annealing processes (especially a full anneal on steel), a very slow cooling rate is essential. Rapid cooling, such as quenching in air or water, will re-introduce stress and harden the material, defeating the purpose of the anneal. The standard practice is to let the part cool down slowly with the furnace over many hours.

Making the Right Choice for Your Goal

To determine the correct annealing parameters, you must first define your material and your objective.

- If your primary focus is working with steel: Consult the iron-carbon phase diagram for your specific steel grade to identify its critical temperatures (A1, A3, Acm) as your guide.

- If your primary focus is non-ferrous metals like copper or aluminum: Reference a reliable metallurgical handbook or the material supplier's data sheet for proven temperature ranges for that specific alloy.

- If your primary focus is achieving maximum softness and ductility: You are likely performing a full anneal, which requires heating above the upper critical temperature and ensuring a very slow furnace cool.

- If your primary focus is relieving stress between manufacturing steps: A lower-temperature "process anneal" or "stress-relief anneal" may be sufficient and more efficient than a full anneal.

Ultimately, successful annealing comes from understanding that temperature is a tool to manipulate a specific material's fundamental properties.

Summary Table:

| Material | Typical Annealing Temperature Range | Key Principle |

|---|---|---|

| Steel | 723°C - 910°C (1333°F - 1670°F) | Heat above upper critical temperature (A3) for full anneal |

| Aluminum Alloys | 300°C - 410°C (570°F - 770°F) | Precise control is critical to avoid overheating |

| Copper/Brass | 370°C - 650°C (700°F - 1200°F) | Driven by recrystallization of cold-worked structure |

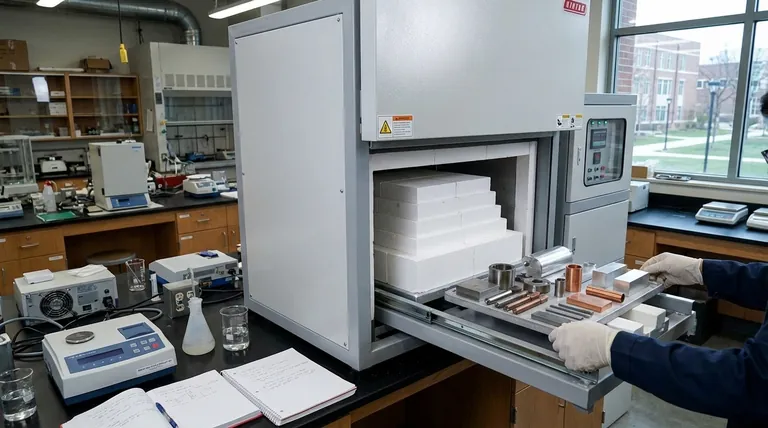

Achieve Perfect Annealing Results with KINTEK

Mastering the precise temperature, soaking time, and cooling rate for your specific material is the key to successful annealing. Whether you are working with steel, aluminum, copper, or other alloys, having the right laboratory furnace is non-negotiable for achieving the desired material properties like ductility and stress relief.

KINTEK specializes in precision lab furnaces and equipment designed for reliable and repeatable heat treatment processes. Our solutions help you avoid the pitfalls of overheating, underheating, and improper cooling, ensuring your materials perform exactly as needed.

Ready to optimize your annealing process? Contact our experts today to find the perfect furnace for your laboratory's specific material science requirements.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Which furnace is generally more efficient? Match the Right Furnace to Your Heating Goals

- What are the three main components of biomass? Unlocking the Secrets of Cellulose, Hemicellulose, and Lignin

- What are sputtering systems used for? A Guide to Advanced Thin-Film Deposition

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What is the high temperature of quartz? Key Thresholds for Crystalline vs. Fused Silica

- What temperature should brazing be? Master the Key to Strong, Reliable Joints

- Why is it necessary to use a constant temperature drying oven for PLLA/ZnO membranes? Ensure Safety & Stability

- What is flash sintering? Achieve Rapid, Energy-Efficient Ceramic Densification