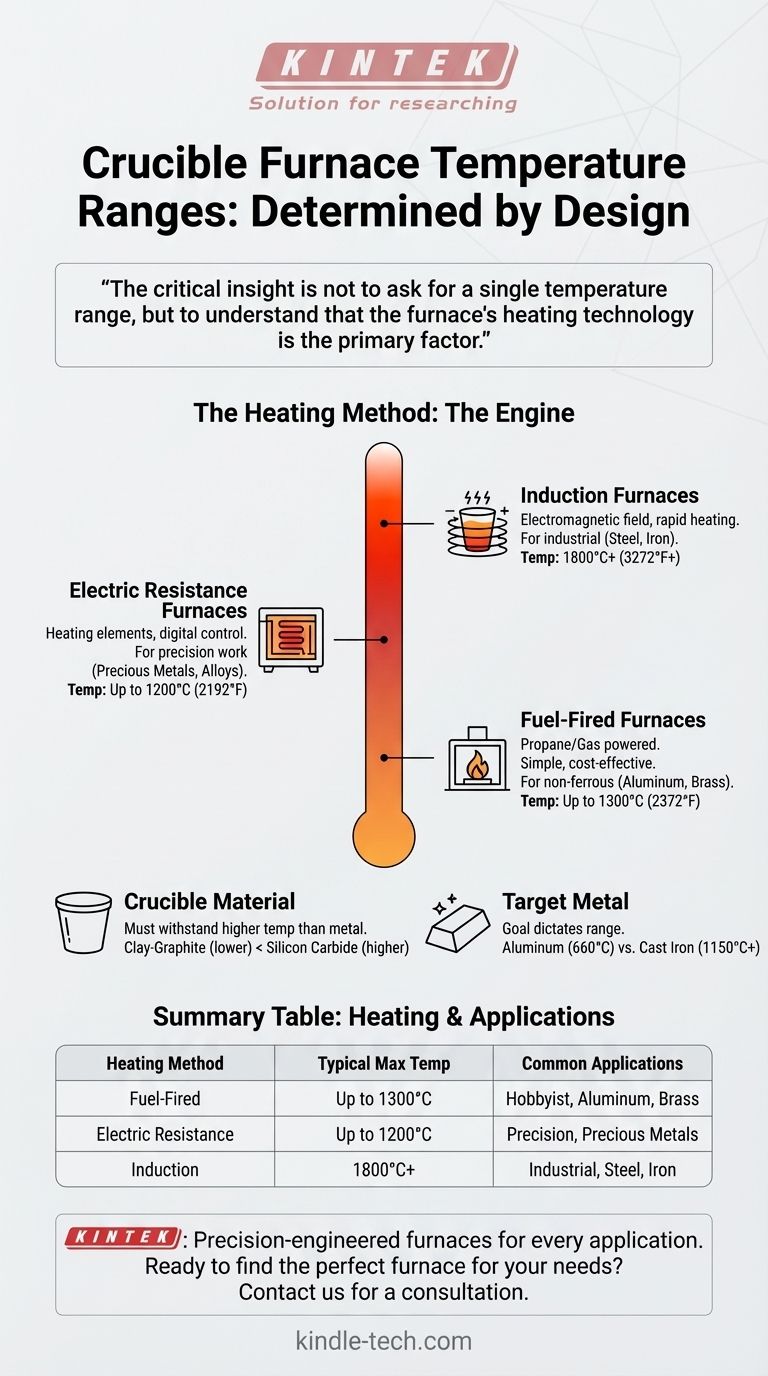

Crucible furnaces operate across a vast temperature spectrum, with the specific range determined entirely by the furnace's design and heating method. Simpler fuel-fired models used by hobbyists may operate around 1100°C (2000°F), while advanced industrial induction furnaces can exceed 1800°C (3272°F) for melting materials like steel and iron.

The critical insight is not to ask for a single temperature range, but to understand that the furnace's heating technology—be it fuel, electric resistance, or induction—is the primary factor that dictates its peak temperature and, therefore, the types of metal it can successfully melt.

What Determines a Crucible Furnace's Temperature?

A furnace's maximum temperature is not an arbitrary number; it's a result of its core design, from the way it generates heat to the materials used in its construction. Understanding these factors is key to selecting the right tool for the job.

The Heating Method: The Engine of the Furnace

The single most important factor is how the furnace generates heat. There are three primary methods.

Fuel-Fired Furnaces: These furnaces, typically powered by propane or natural gas, are common for hobbyists and small foundries. They are relatively simple and cost-effective but offer less precise temperature control. Their range is generally suitable for non-ferrous metals like aluminum, brass, and bronze, often reaching up to 1300°C (2372°F).

Electric Resistance Furnaces: These use heating elements, much like a kiln, to generate heat. They offer excellent temperature control, often managed by a digital PID controller. This makes them ideal for applications requiring precision, such as working with precious metals or specific alloys. They typically operate in a range up to 1200°C (2192°F), with specialized models going higher.

Induction Furnaces: Representing the high end of performance, induction furnaces do not use an external heating element. Instead, a powerful coil creates a strong electromagnetic field that directly and rapidly heats the conductive metal inside the crucible. This method is incredibly efficient and is the standard for industrial applications involving steel and iron, capable of reaching 1800°C (3272°F) or more.

The Crucible Material: The Weakest Link

The crucible itself is a critical limiting factor. It must be able to withstand a temperature significantly higher than the melting point of the metal it contains.

Using a crucible beyond its rated temperature will lead to rapid degradation and catastrophic failure. Common materials include clay-graphite for lower-temperature non-ferrous metals and silicon carbide or advanced ceramics for higher-temperature applications.

The Target Metal: The Goal of the Process

The temperature range you need is ultimately defined by the metal you wish to melt.

A furnace must be able to comfortably exceed the target metal's melting point to ensure a fully liquid and pourable charge. For example, melting aluminum (660°C / 1220°F) has vastly different requirements than melting cast iron (1150 - 1200°C / 2100 - 2200°F).

Understanding the Trade-offs

Choosing a furnace involves balancing performance, cost, and complexity. No single type is best for every situation.

Cost vs. Performance

There is a direct correlation between cost and temperature capability. Fuel-fired furnaces are the most affordable entry point, while industrial induction furnaces represent a significant capital investment.

Control vs. Simplicity

Electric resistance furnaces offer "set it and forget it" precision, which is invaluable for sensitive alloys. Fuel-fired furnaces require more operator skill to manage the fuel/air mixture and maintain a stable temperature.

Infrastructure and Safety

Each furnace type has unique requirements. Fuel-fired models require proper ventilation for combustion gases and safe fuel storage. High-power electric resistance and induction furnaces demand significant electrical infrastructure that may not be available in a standard workshop.

Making the Right Choice for Your Application

To select the correct furnace, start by identifying your primary goal and the materials you will be working with.

- If your primary focus is hobbyist metal casting (aluminum, brass): A propane-fired furnace offers the most accessible and cost-effective solution for reaching the required temperatures.

- If your primary focus is precision work with precious metals or lab-grade alloys: An electric resistance furnace provides the unparalleled temperature control and clean environment you need.

- If your primary focus is high-volume or industrial melting of steel and iron: An induction furnace is the only practical choice, delivering the extreme temperatures and rapid melting rates necessary for production.

By matching the furnace technology to your specific material and goals, you ensure an efficient, safe, and successful melting operation.

Summary Table:

| Heating Method | Typical Max Temperature | Common Applications |

|---|---|---|

| Fuel-Fired (Propane/Gas) | Up to 1300°C (2372°F) | Hobbyist casting, aluminum, brass, bronze |

| Electric Resistance | Up to 1200°C (2192°F) | Precision work, precious metals, lab alloys |

| Induction | 1800°C+ (3272°F+) | Industrial steel, iron, high-volume melting |

Ready to find the perfect crucible furnace for your specific metals and melting requirements?

KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision-engineered furnaces for every application—from hobbyist workshops to industrial foundries. Our experts will help you select the ideal furnace based on your target metals, desired temperature range, and operational goals.

Contact KINTEK today for a personalized consultation and discover how our reliable, high-performance furnaces can enhance your melting efficiency and safety.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vertical Laboratory Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How are carbon crucibles made? Discover the Engineering Behind High-Performance Crucibles

- What are the advantages of using high-purity alumina crucibles for YSC powders? Ensure Chemical Purity & Stability

- What temperature is an Al2O3 crucible? Key Factors for High-Temperature Success Up to 1700°C

- What can be used as a crucible for melting gold? A Guide to Graphite, Quartz, and More

- What is the function of a ceramic crucible with a borosilicate glaze? Ensure Purity in SrFeO3 Nanocrystal Synthesis

- How many times can you use a crucible? Maximize Lifespan and Ensure Safety

- What is the primary function of a stainless steel crucible in studies involving liquid lead? Essential Lab Insights

- Why must aluminum alloys be heated in alumina crucibles? Ensure Pure Results in Molten Corrosion Experiments