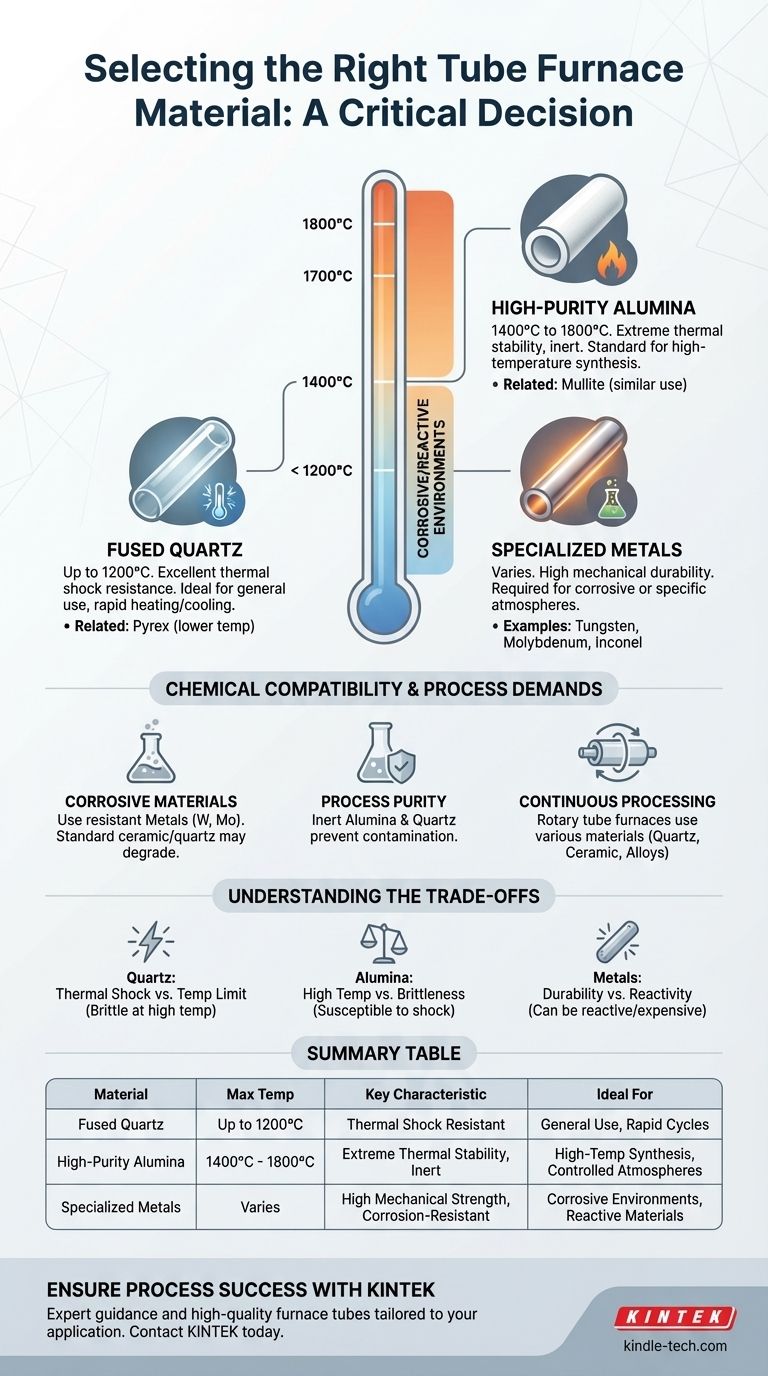

The material used for a furnace tube is not a minor detail; it is the most critical component defining the furnace's capabilities. The most common materials are high-purity alumina, fused quartz, and specialized metals. The final selection is a direct function of your required operating temperature and the chemical nature of the materials being processed.

The choice of a furnace tube is a critical decision driven primarily by its maximum operating temperature. While fused quartz is suitable for processes up to 1200°C, high-purity alumina is the standard for higher temperatures, and specialized metals are required for corrosive or highly specific environments.

The Core Selection Factor: Operating Temperature

The single most important variable in choosing a tube material is the maximum temperature of your process. This factor immediately narrows your options into distinct categories.

Fused Quartz (Up to 1200°C)

For many applications operating at or below 1200°C, a fused quartz tube is the standard choice. Its excellent thermal shock resistance makes it robust during rapid heating and cooling cycles.

Related glass materials, like Pyrex, can also be used, but they have a significantly lower maximum operating temperature and are less common in high-performance laboratory furnaces.

High-Purity Alumina (1400°C to 1800°C)

When processes demand temperatures above 1200°C, high-purity alumina becomes the essential material. This robust ceramic is supplied for furnaces rated for 1400°C, 1700°C, and even 1800°C.

Other ceramic materials, such as mullite, serve a similar purpose, providing thermal stability in demanding, high-heat environments.

Chemical Compatibility and Process Demands

Beyond temperature, the chemical interaction between the tube and the sample material dictates the correct choice. The furnace's design, such as a rotary system, also influences material selection.

Handling Corrosive Materials

If your process involves corrosive substances, standard ceramic or quartz tubes may degrade or react with your sample.

In these specific cases, tubes made of highly resistant metals like tungsten or molybdenum are required to maintain the integrity of both the tube and the process.

Ensuring Process Purity

Tube furnaces are often used for creating advanced materials in highly controlled, specialty atmospheres.

Materials like high-purity alumina and fused quartz are chosen for these applications because they are inert and do not introduce contaminants into the process environment.

Accommodating Continuous Processing

Rotary tube furnaces are designed for the continuous processing of powders, granules, or other aggregates.

The rotating tube component in these systems can be made from quartz, ceramic, or high-temperature alloys like Inconel or stainless steel, depending on the temperature and material flow requirements.

Understanding the Trade-offs

Every material presents a balance of benefits and limitations. Understanding these trade-offs is key to preventing process failure and ensuring safety.

Quartz: Thermal Shock vs. Temperature Limit

A key advantage of quartz is its exceptional resistance to thermal shock. However, its utility is strictly limited to processes that do not exceed approximately 1200°C.

Alumina: High Temperature vs. Brittleness

Alumina's primary strength is its ability to withstand extreme heat. Its main drawback is its brittle nature, making it more susceptible to cracking from severe thermal shock compared to quartz.

Metals: Durability vs. Potential Reactivity

Metal tubes, such as stainless steel or Inconel, offer excellent mechanical durability. However, they can be reactive with certain samples or atmospheres at high temperatures and are often a more expensive solution.

Making the Right Choice for Your Process

Your selection should be guided directly by the primary goal of your thermal process.

- If your primary focus is general use up to 1200°C: A fused quartz tube offers the best balance of thermal shock resistance and high-purity performance.

- If your primary focus is high-temperature synthesis above 1200°C: High-purity alumina is the non-negotiable industry standard required for thermal stability.

- If your primary focus is processing corrosive or reactive materials: You must select a specialized metal tube, such as tungsten, molybdenum, or a high-temperature alloy, to ensure process integrity.

Selecting the correct tube material is the foundational step toward achieving reliable, repeatable, and safe results in your work.

Summary Table:

| Material | Max Temperature | Key Characteristics | Ideal For |

|---|---|---|---|

| Fused Quartz | Up to 1200°C | Excellent thermal shock resistance, high purity | General use, rapid heating/cooling cycles |

| High-Purity Alumina | 1400°C - 1800°C | Extreme thermal stability, inert | High-temperature synthesis, controlled atmospheres |

| Specialized Metals | Varies | High mechanical strength, corrosion-resistant | Corrosive environments, reactive materials |

Ensure Your Process Success with the Right Tube

Choosing the correct furnace tube is critical for the safety, reliability, and purity of your laboratory work. The wrong material can lead to contamination, process failure, or even equipment damage.

KINTEK specializes in lab equipment and consumables, providing expert guidance and high-quality furnace tubes tailored to your specific application—whether you require the thermal shock resistance of quartz, the high-temperature stability of alumina, or the durability of specialized metals.

Let our experts help you select the perfect tube for your needs. Contact KINTEK today to discuss your process requirements and ensure optimal performance for your research or production.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is the function of a horizontal tube furnace in simulating the oxidation behavior of hot-rolled steel? Expert Guide

- How does a horizontal high-temperature tube furnace evaluate oxidation? Quantifying Coating Durability at 1100°C

- How do vertical split tube furnaces and preheaters facilitate SCWO? Achieve Optimal Supercritical Water Oxidation

- Why is a high-precision tube furnace required for CVD metal oxide films? Ensure Purity and Uniformity

- How does high-temperature treatment in a tube furnace affect biochar-MOF? Unlock High-Conductivity Nanocomposites

- Why is a tube reduction furnace required for Fe-Cu powders? Eliminate Oxides for Superior Sintering Results

- What is the basic construction and temperature control mechanism of a laboratory tube furnace? Master Precision Heating for Your Lab

- What role do tube or muffle furnaces play in fluorinated LPSCl electrolyte prep? Master Solid-State Synthesis