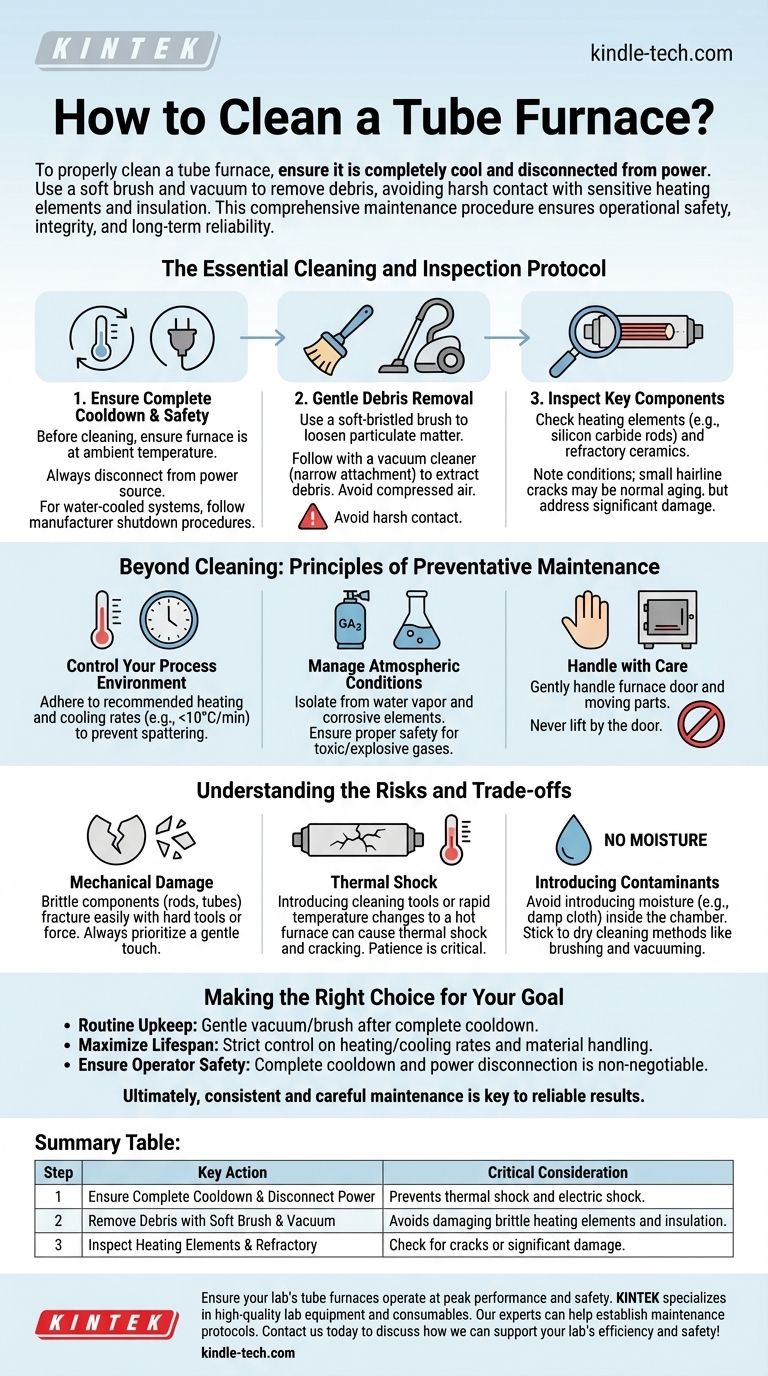

To properly clean a tube furnace, you must first allow it to cool down completely and ensure it is disconnected from power. Once safe, use a soft brush and a vacuum cleaner to gently remove any loose debris or residue from inside the furnace tube. It is critical to avoid harsh contact with the sensitive heating elements and the furnace's insulation during this process.

The goal of cleaning a tube furnace extends beyond simply removing visible debris. It is a comprehensive maintenance procedure that involves careful preparation, gentle execution, and thorough inspection to ensure operational safety, process integrity, and the long-term reliability of the equipment.

The Essential Cleaning and Inspection Protocol

A systematic approach ensures that you clean the furnace effectively without causing accidental damage. This protocol should be a standard part of your lab's maintenance schedule.

Step 1: Ensure Complete Cooldown and Safety

Before any cleaning begins, the furnace must be at ambient temperature. Attempting to clean a warm or hot furnace poses a severe safety risk and can cause thermal shock to the components.

Always disconnect the furnace from its power source to prevent any possibility of electric shock. If your system uses water cooling, follow the manufacturer's shutdown procedure; this often involves stopping the heater first, then turning off the cooling water once the furnace temperature drops below 200°C.

Step 2: Gentle Debris Removal

Use a soft-bristled brush to carefully loosen any particulate matter, ash, or process residue from the inner surfaces of the furnace tube.

Follow with a vacuum cleaner using a narrow attachment to extract all the loose debris. This method is preferred over compressed air, which can drive particles into the insulation or damage delicate components.

Step 3: Inspect Key Components

Cleaning provides a perfect opportunity for inspection. Look closely at the heating elements (like silicon carbide rods) and the refractory ceramics or insulation.

Note the condition of these parts. Small, hairline cracks on the surface of refractory ceramics can be a normal sign of aging from repeated thermal cycles and may not require immediate action. However, significant damage or erosion should be addressed.

Beyond Cleaning: Principles of Preventative Maintenance

The most effective cleaning strategy is to minimize contamination in the first place. Proper operational habits are crucial for the furnace's longevity and performance.

Control Your Process Environment

Contamination of the furnace tube often occurs when materials are heated or cooled too quickly, causing them to spatter. Adhere to recommended heating and cooling rates, which should generally not exceed 10°C per minute.

Manage Atmospheric Conditions

Preventative maintenance includes managing the atmosphere within the furnace. Isolate the furnace from water vapor and other corrosive elements that can degrade components over time.

If you are using toxic or explosive gases, ensure all necessary safety controls, ventilation, and professional supervision are in place.

Handle with Care

Mechanical damage is a common and preventable issue. Always handle the furnace door and other moving parts gently. Lifting the furnace by its door is strictly prohibited as it can cause serious damage to the assembly.

Understanding the Risks and Trade-offs

Improper cleaning or maintenance introduces significant risks. Understanding these trade-offs is key to making informed decisions.

The Risk of Mechanical Damage

The internal components of a tube furnace, particularly silicon carbide rods and ceramic tubes, are brittle. Using hard tools, applying excessive force, or bumping components can lead to costly fractures. Always prioritize a gentle touch.

The Risk of Thermal Shock

Introducing any cleaning tools or even a rapid change in air temperature to a hot furnace can cause thermal shock, cracking the furnace tube or heating elements. Patience during the cooldown phase is not optional; it is a critical safety and maintenance step.

The Risk of Introducing Contaminants

While a damp cloth might be suitable for a furnace's exterior, avoid introducing moisture inside the furnace chamber. Water can be absorbed by the insulation and cause significant problems during the next heating cycle. Stick to dry cleaning methods like brushing and vacuuming.

Making the Right Choice for Your Goal

Your approach to maintenance should align with your operational priorities.

- If your primary focus is routine upkeep: Perform a gentle vacuum and brush cleaning regularly after the furnace has completely cooled to prevent significant buildup.

- If your primary focus is maximizing furnace lifespan: Implement strict controls on heating/cooling rates and material handling to prevent internal contamination from the start.

- If your primary focus is ensuring operator safety: Always make a complete cooldown and power disconnection your non-negotiable first step before any hands-on maintenance.

Ultimately, consistent and careful maintenance is the key to achieving reliable, repeatable results from your tube furnace.

Summary Table:

| Step | Key Action | Critical Consideration |

|---|---|---|

| 1 | Ensure Complete Cooldown & Disconnect Power | Prevents thermal shock and electric shock. |

| 2 | Remove Debris with Soft Brush & Vacuum | Avoids damaging brittle heating elements and insulation. |

| 3 | Inspect Heating Elements & Refractory | Check for cracks or significant damage. |

Ensure your lab's tube furnaces operate at peak performance and safety. Proper maintenance is critical for reliable results and equipment longevity. KINTEK specializes in high-quality lab equipment, including tube furnaces, and consumables, serving all your laboratory needs. Our experts can help you establish the right maintenance protocols. Contact us today to discuss how we can support your lab's efficiency and safety!

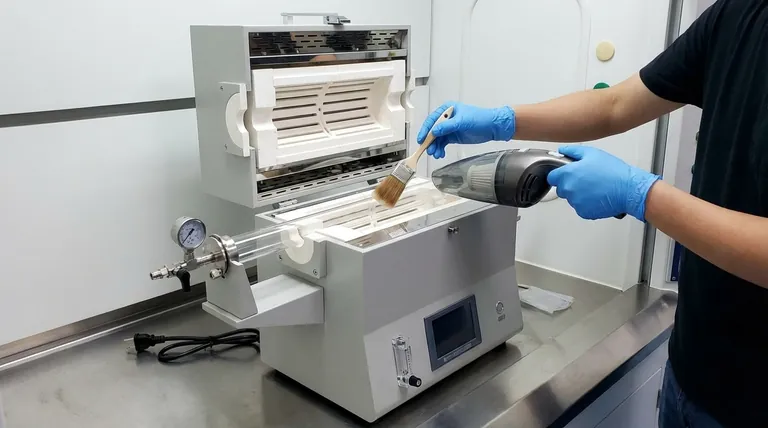

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the function of a Vacuum Tube Furnace in UCF pre-treatment? Optimize Your Composite Material Fabrication

- What advantages does a vacuum tube sintering furnace offer for ceramic hollow fiber membranes? Enhance Performance.

- What is the necessity of using a vacuum tube furnace for Boron Carbide (B4C)? Achieve Optimal Preform Sintering

- Does pyrolysis produce biogas? Discover the Syngas Difference for Your Lab

- Why is a combustion tube set to 1150 °C for asphaltene analysis? Unlock Precise Elemental Quantification

- What is the role of secondary calcination in tube or box furnaces? Enhance Sodium-Ion Battery Stability and Performance

- What is the role of high-precision laboratory tube furnaces in the development of heterojunction photocatalysts?

- How is a laboratory tube furnace used to evaluate the resistance of rare earth catalysts to flue gas impurities?