The primary tests for a refractory material evaluate its performance under the combined stresses of extreme heat and mechanical load. These thermo-mechanical tests measure critical properties like its load-bearing capacity at high temperatures (Refractoriness Under Load), its long-term deformation (Creep), its physical stability (Thermal Expansion), and its resistance to sudden temperature changes (Thermal Shock Resistance).

The true measure of a refractory is not simply its melting point, but its ability to maintain structural integrity and perform its function under the specific thermal and mechanical stresses of its intended environment. These tests are designed to predict that real-world performance.

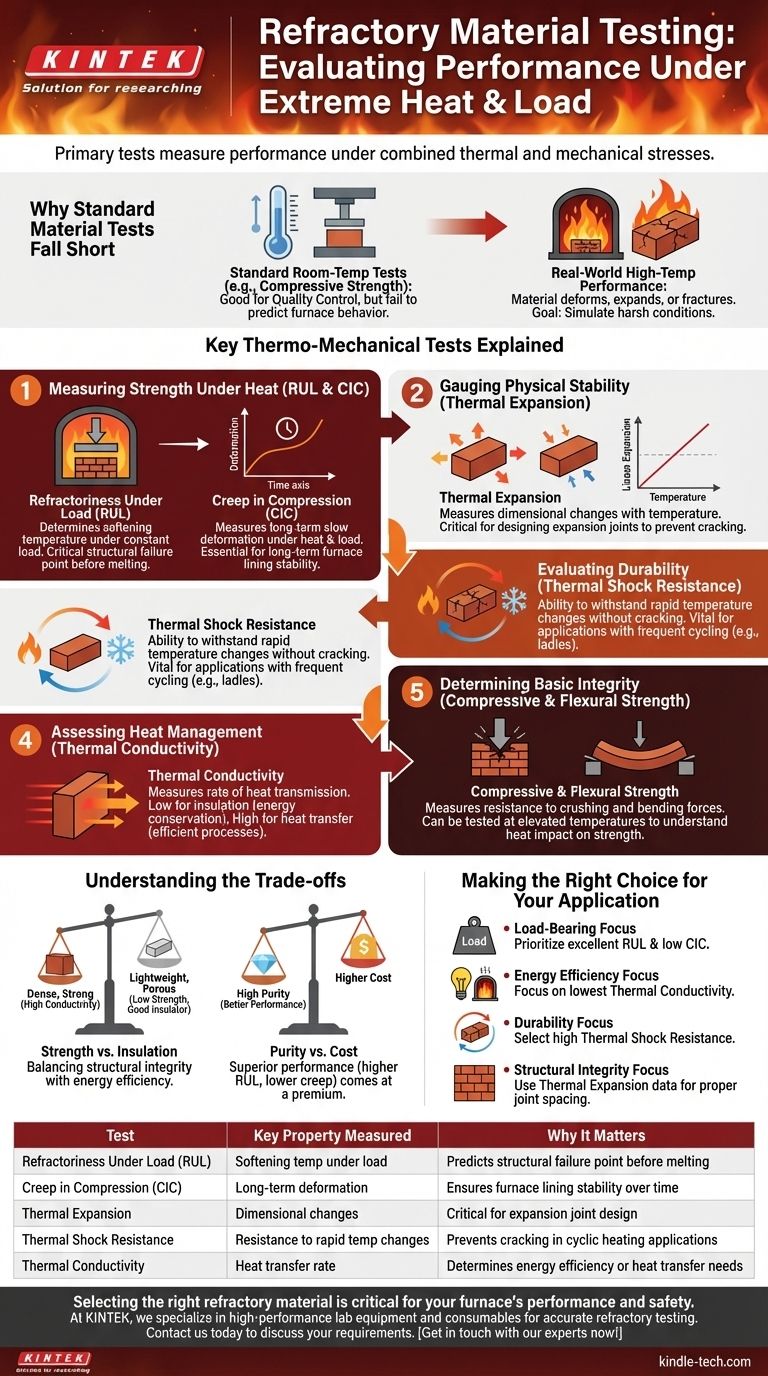

Why Standard Material Tests Fall Short

A refractory material's defining characteristic is its performance at extremely high temperatures. Standard room-temperature tests for properties like compressive strength are useful for quality control but fail to predict how the material will behave inside a furnace, kiln, or reactor.

The goal of refractory testing is to simulate these harsh conditions to understand how the material will deform, expand, or fracture over its service life.

Key Thermo-Mechanical Tests Explained

Each test reveals a different aspect of the material's high-temperature behavior, painting a complete picture of its suitability for a specific application.

Measuring Strength Under Heat (RUL & CIC)

Refractoriness Under Load (RUL) determines the temperature at which the material begins to soften and deform under a constant, specified load. This is often a more critical data point than the melting point itself, as a material can fail structurally long before it melts.

Creep in Compression (CIC) is a longer-duration test that measures how a refractory deforms slowly over time under a constant load and temperature. This is essential for predicting the long-term stability of a furnace lining, as even minor creep can accumulate over months to cause structural failure.

Gauging Physical Stability (Thermal Expansion)

This test measures how much the material expands when heated and contracts when cooled. Understanding a refractory's coefficient of thermal expansion is critical for designing furnace linings, requiring precise calculations for expansion joints to prevent cracking and spalling during heat-up and cool-down cycles.

Evaluating Durability (Thermal Shock Resistance)

Thermal shock resistance is a material's ability to withstand rapid changes in temperature without cracking. Refractories in applications like kiln doors or ladles, which experience frequent and sudden heating and cooling, must have excellent resistance to thermal shock to ensure a safe and long service life.

Assessing Heat Management (Thermal Conductivity)

This property measures the rate at which heat is transmitted through the refractory. For insulating firebricks, low thermal conductivity is the primary goal to conserve energy. For other applications, like crucibles, high thermal conductivity may be desired for efficient heat transfer.

Determining Basic Integrity (Compressive & Flexural Strength)

These tests measure the material's ability to resist crushing forces (compressive) and bending or flexing forces (flexural). While often performed at room temperature for quality assurance, they can also be conducted at elevated temperatures (up to 1550°C) to understand how heat impacts the material's fundamental brittleness and strength.

Understanding the Trade-offs

Selecting a refractory material always involves balancing competing properties. No single material is perfect for every application.

Strength vs. Insulation

Dense, strong refractory bricks typically have higher thermal conductivity, making them poor insulators. Conversely, lightweight, highly porous insulating bricks have low strength and are unsuitable for load-bearing applications.

Purity vs. Cost

Generally, refractories with higher purity (e.g., high-alumina or magnesia content) exhibit better performance, such as a higher RUL and lower creep. This superior performance comes at a significantly higher cost.

Lab Data vs. Service Conditions

It is crucial to remember that these standardized tests are performed in a controlled lab environment. Real-world service conditions involving chemical attack from slag, specific furnace atmospheres, and abrasion will also profoundly impact the refractory's lifespan.

Making the Right Choice for Your Application

Use test data to align a material's proven characteristics with the demands of your specific environment.

- If your primary focus is load-bearing in a stable, high-heat furnace: Prioritize materials with excellent Refractoriness Under Load (RUL) and low Creep in Compression (CIC) values.

- If your primary focus is energy efficiency and insulation: Focus on materials with the lowest possible Thermal Conductivity that can still handle the service temperature.

- If your primary focus is durability in a process with rapid heating and cooling cycles: Select a material with a proven high resistance to Thermal Shock.

- If your primary focus is building a structurally sound lining: Use Thermal Expansion data to engineer the correct spacing for expansion joints and prevent mechanical failure.

Ultimately, understanding these key tests empowers you to select a refractory based on predictable performance, not just its chemical composition.

Summary Table:

| Test | Key Property Measured | Why It Matters |

|---|---|---|

| Refractoriness Under Load (RUL) | Softening temperature under load | Predicts structural failure point before melting |

| Creep in Compression (CIC) | Long-term deformation under heat & load | Ensures furnace lining stability over time |

| Thermal Expansion | Dimensional changes with temperature | Critical for expansion joint design |

| Thermal Shock Resistance | Resistance to rapid temperature changes | Prevents cracking in cyclic heating applications |

| Thermal Conductivity | Heat transfer rate | Determines energy efficiency or heat transfer needs |

Selecting the right refractory material is critical for your furnace's performance and safety. At KINTEK, we specialize in providing high-performance lab equipment and consumables for accurate refractory testing and analysis. Our expertise helps you match material properties to your specific high-temperature application needs, ensuring optimal efficiency and longevity. Contact us today to discuss your refractory testing requirements and let our specialists help you make the right choice for your laboratory. Get in touch with our experts now!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Anti-Cracking Press Mold for Lab Use

- Bomb Type Probe for Steelmaking Production Process

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Hydrogen Determination Probe for Quickly Measuring Hydrogen Content with High Success Rate

People Also Ask

- What is the temperature range of a MoSi2 heating element? Unlock 1900°C Performance for Your Lab

- What is the temperature range of molybdenum disilicide heating elements? Choose the Right Grade for Your High-Temp Needs

- What is molybdenum disilicide used for? Powering High-Temperature Furnaces Up to 1800°C

- Which material is suitable for use in heating elements? Match the Right Material to Your Temperature and Atmosphere

- What material is used for furnace heating? Select the Right Element for Your Process