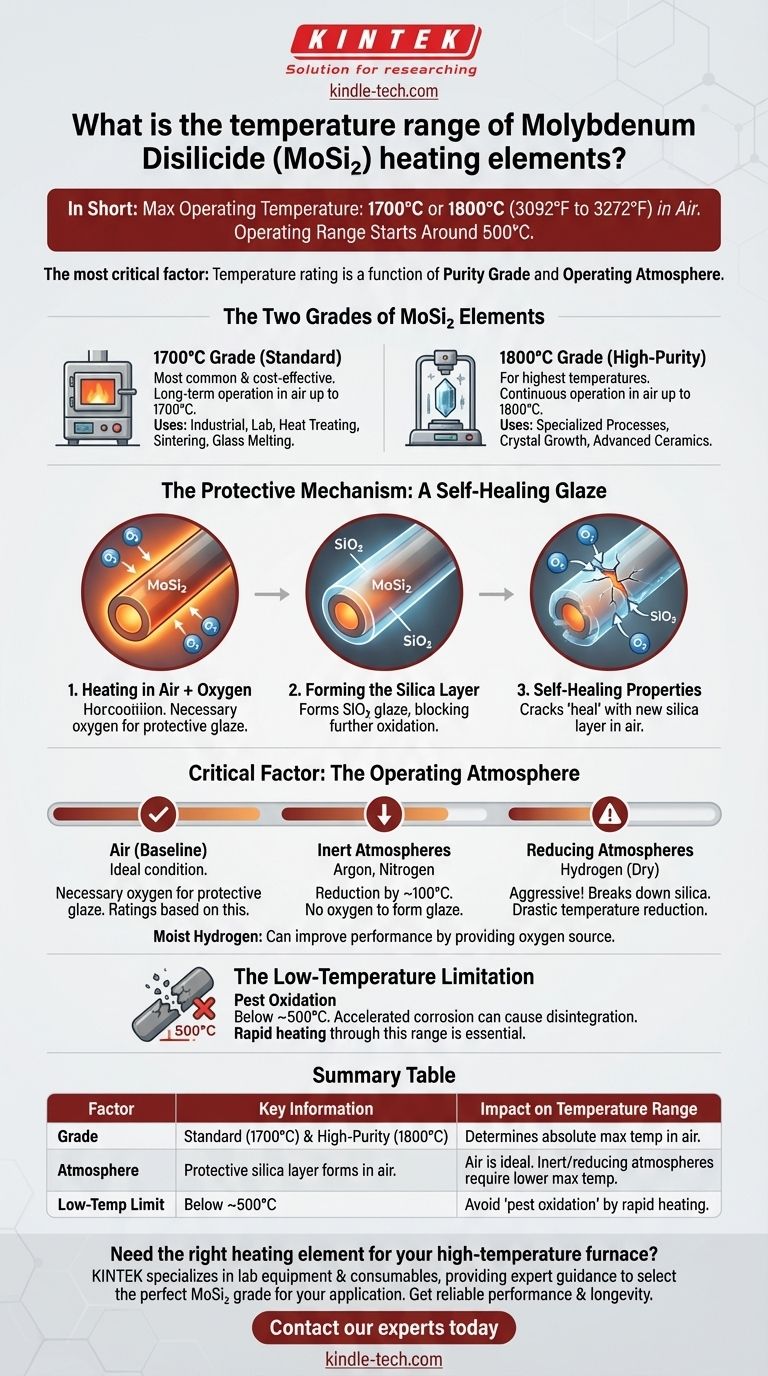

In short, the maximum operating temperature for Molybdenum Disilicide (MoSi₂) heating elements is typically 1700°C or 1800°C (3092°F to 3272°F), depending on the specific grade of the element. However, this rating is for operation in air, and the effective temperature range is significantly influenced by the surrounding atmosphere. The general operating range starts around 500°C.

The most critical factor to understand is that a MoSi₂ element's temperature rating is not a single, universal number. It is a function of two key variables: the element's purity grade (which determines its absolute maximum temperature in air) and the operating atmosphere, which can significantly lower that maximum.

The Two Grades of MoSi₂ Elements

Molybdenum disilicide heaters are not a one-size-fits-all component. They are manufactured in distinct grades, which directly dictates their peak performance capabilities.

The 1700°C Grade (Standard)

This is the most common and cost-effective type of MoSi₂ heating element. It is designed for long-term, stable operation in furnaces with a maximum chamber temperature of 1700°C.

These elements are widely used in industrial and laboratory applications, from heat treating and sintering to glass melting.

The 1800°C Grade (High-Purity)

For applications requiring the highest possible temperatures, a higher-purity grade is available. These elements can operate continuously with a furnace temperature of 1800°C.

This grade is more expensive and is reserved for specialized processes, such as growing certain types of crystals or sintering advanced ceramics.

The Protective Mechanism: A Self-Healing Glaze

The remarkable high-temperature capability of MoSi₂ elements comes from a unique property: the formation of a protective surface layer.

Forming the Silica Layer

When heated in an oxidizing atmosphere (like air), the element's surface reacts with oxygen to form a thin, non-porous layer of silica dioxide (SiO₂), which is essentially a glass-like glaze.

This glaze is what protects the underlying molybdenum disilicide from further high-temperature oxidation and chemical attack, allowing it to function at extreme temperatures.

Self-Healing Properties

If this protective glaze is ever cracked or damaged, the exposed MoSi₂ material underneath will immediately react with the air, "healing" the breach with a new layer of silica. This gives the elements a very long and reliable service life.

Critical Factor: The Operating Atmosphere

The maximum temperature ratings are almost always specified for operation in air. Using these elements in any other atmosphere requires careful consideration and often a reduction in the maximum allowable temperature.

Operation in Air (The Baseline)

Air provides the oxygen necessary to form and maintain the protective silica layer. The 1700°C and 1800°C ratings are based on this ideal condition.

The Impact of Inert Atmospheres

In inert atmospheres like argon or nitrogen, there is no free oxygen to form or repair the protective glaze. This forces a reduction in the maximum operating temperature, typically by at least 100°C.

The Challenge of Reducing Atmospheres

Reducing atmospheres, particularly those containing hydrogen, are even more aggressive. Even a small percentage of hydrogen can actively break down the silica layer, drastically lowering the element's maximum safe operating temperature.

However, using moist hydrogen can paradoxically improve performance by providing an oxygen source (from the water vapor) to help regenerate the protective glaze.

The Low-Temperature Limitation

MoSi₂ elements are not effective at low temperatures. Below approximately 500°C, they can suffer from a phenomenon known as "pest oxidation," a form of accelerated corrosion that can cause the element to disintegrate. They must be heated rapidly through this range.

Making the Right Choice for Your Application

Selecting the correct heating element requires you to look beyond the maximum temperature and consider the specific conditions of your process.

- If your primary focus is standard high-temperature processes in an air furnace: The 1700°C grade is the reliable and cost-effective workhorse for most applications.

- If your primary focus is achieving the absolute highest temperatures in air: You must specify and use the more expensive 1800°C high-purity grade.

- If your primary focus is operating in a non-air atmosphere (inert or reducing): You must de-rate the element's maximum temperature and consult manufacturer data for your specific gas composition to ensure element longevity.

Understanding these factors is the key to achieving stable, reliable performance from your high-temperature equipment.

Summary Table:

| Factor | Key Information | Impact on Temperature Range |

|---|---|---|

| Grade | Two main grades: Standard (1700°C) and High-Purity (1800°C). | Determines the absolute maximum operating temperature in air. |

| Atmosphere | Protective silica layer forms in air. | Air is ideal. Inert/reducing atmospheres require a lower max temperature (e.g., -100°C). |

| Low-Temperature Limit | Below ~500°C. | Elements must be heated quickly through this range to avoid 'pest oxidation'. |

Need the right heating element for your high-temperature furnace?

KINTEK specializes in lab equipment and consumables, providing expert guidance to help you select the perfect MoSi₂ heating element grade for your specific application and atmosphere. We ensure you get reliable performance and maximum longevity for your sintering, heat treatment, or crystal growth processes.

Contact our experts today to discuss your requirements and get a personalized recommendation!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Is molybdenum disulfide a heating element? Discover the best material for high-temperature applications.

- What function do molybdenum disilicide heating elements perform? Precision Heat for Pulverized Coal Research

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance

- What material is used for furnace heating? Select the Right Element for Your Process

- What is the temperature range of a MoSi2 heating element? Unlock 1900°C Performance for Your Lab