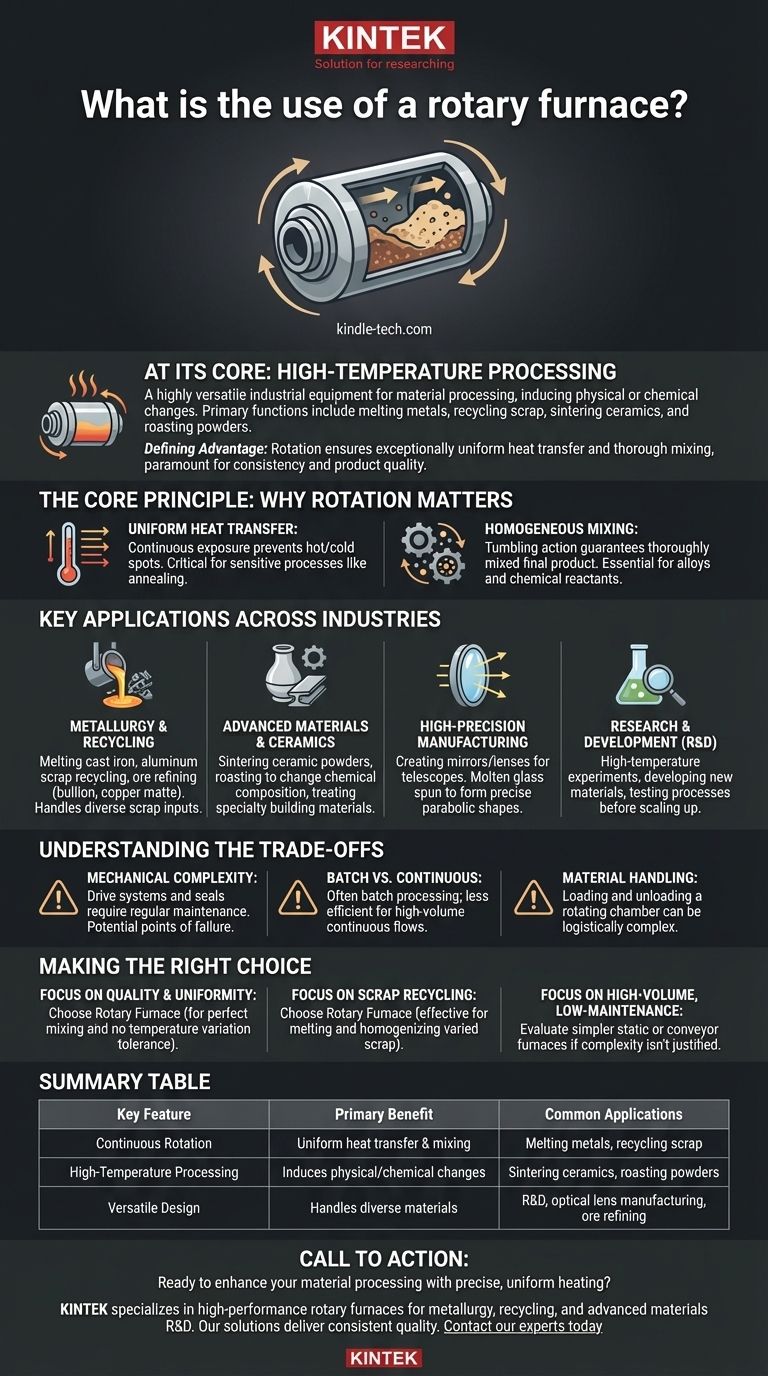

At its core, a rotary furnace is a highly versatile piece of industrial equipment used for a wide range of high-temperature material processing applications. Its primary function is to heat materials to induce a physical or chemical change, from melting metals and recycling scrap to sintering advanced ceramics and roasting chemical powders.

The defining advantage of a rotary furnace is its rotation. By constantly tumbling the material within its cylindrical chamber, it ensures exceptionally uniform heat transfer and thorough mixing, making it the ideal choice for processes where consistency and product quality are paramount.

The Core Principle: Why Rotation Matters

Unlike a static furnace that heats a stationary load, a rotary furnace's entire design philosophy revolves around movement. This simple principle provides two powerful benefits that enable its wide range of applications.

Achieving Uniform Heat Transfer

The rotation continuously exposes all surfaces of the material to the heat source, whether it's a direct flame or heated gas. This prevents hot spots and cold spots, ensuring the entire batch is processed at a consistent temperature.

This level of thermal uniformity is critical for sensitive processes like annealing, where precise temperature control dictates the final properties of the material.

Ensuring Homogeneous Mixing

For processes involving powders or mixed materials, the tumbling action guarantees a thoroughly mixed, homogeneous final product.

This is essential in metallurgy for creating consistent alloys from scrap metal or in the chemical industry for ensuring reactants are fully integrated during a process.

Key Applications Across Industries

The combination of uniform heating and mixing makes the rotary furnace a flexible tool used in numerous fields, from heavy industry to scientific research.

Metallurgy and Recycling

This is one of the most common applications. Rotary furnaces are used to melt cast iron, recycle aluminum scrap, and refine ores into high-purity metals like bullion or copper matte.

The furnace's ability to handle and mix diverse scrap inputs makes it a flexible and universal tool for metal recycling operations.

Advanced Materials and Ceramics

The precise temperature control makes these furnaces ideal for creating advanced materials. They are widely used for sintering ceramic powders, roasting materials to change their chemical composition, and treating specialty building materials.

High-Precision Manufacturing

A notable application is the creation of primary mirrors and lenses for large optical telescopes. Molten glass is spun within the furnace, using centrifugal force and uniform heat to form the precise parabolic shape required for optics.

Research and Development

On a smaller scale, rotary furnaces are indispensable in scientific institutes and R&D labs. They are used for high-temperature experiments, developing new materials, and testing processes before scaling them up for industrial production.

Understanding the Trade-offs

While incredibly versatile, the design of a rotary furnace presents specific operational considerations.

Mechanical Complexity

The drive systems—whether gears, chains, or friction rollers—and the seals at either end of the rotating drum are moving parts. These components require regular maintenance and can be points of failure not present in simpler, static furnaces.

Batch vs. Continuous Processing

Many rotary furnaces are designed for batch processing, where one load is processed at a time. This may be less efficient for certain high-volume production lines that benefit from a continuous flow of material.

Material Handling

Loading and unloading a rotating chamber can be more complex than simply opening the door of a box furnace. The logistics of feeding material in and safely extracting the finished product must be carefully managed.

Making the Right Choice for Your Process

Ultimately, selecting a rotary furnace depends entirely on the requirements of your specific application.

- If your primary focus is product quality and uniformity: The rotary furnace is an exceptional choice for any process that cannot tolerate temperature variations or requires perfect mixing.

- If your primary focus is flexible scrap metal recycling: This furnace is highly effective at melting and homogenizing varied batches of cast iron or aluminum scrap.

- If your primary focus is high-volume, low-maintenance heating: You should evaluate whether the added mechanical complexity is justified, or if a simpler static or conveyor furnace might better suit your needs.

By leveraging controlled rotation, the rotary furnace delivers a level of process control and product consistency that is essential for modern material science and industrial production.

Summary Table:

| Key Feature | Primary Benefit | Common Applications |

|---|---|---|

| Continuous Rotation | Uniform heat transfer & mixing | Melting metals, recycling scrap |

| High-Temperature Processing | Induces physical/chemical changes | Sintering ceramics, roasting powders |

| Versatile Design | Handles diverse materials | R&D, optical lens manufacturing, ore refining |

Ready to enhance your material processing with precise, uniform heating? KINTEK specializes in high-performance rotary furnaces and lab equipment designed for industries like metallurgy, recycling, and advanced materials R&D. Our solutions deliver the consistent quality and reliability your processes demand. Contact our experts today to find the perfect furnace for your application!

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is pyrolysis process for waste? Turn Trash into Valuable Fuel and Products

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies

- What is the purpose of pyrolysis? Transforming Waste into Valuable Energy and Materials

- What are the negative effects of plastic pyrolysis? The Hidden Environmental and Health Risks

- What is fast pyrolysis of plastic waste? Transform Waste Plastic into Valuable Oil

- What is the end product of pyrolysis? Transform Waste into Biochar, Bio-oil, and Syngas

- Why is a vacuum reactor with a rotary drum required for applying oxide coatings to iron powder? Achieve Pure Uniformity

- What is the effect of pyrolysis? Converting Waste into Fuel, Chemicals, and Energy