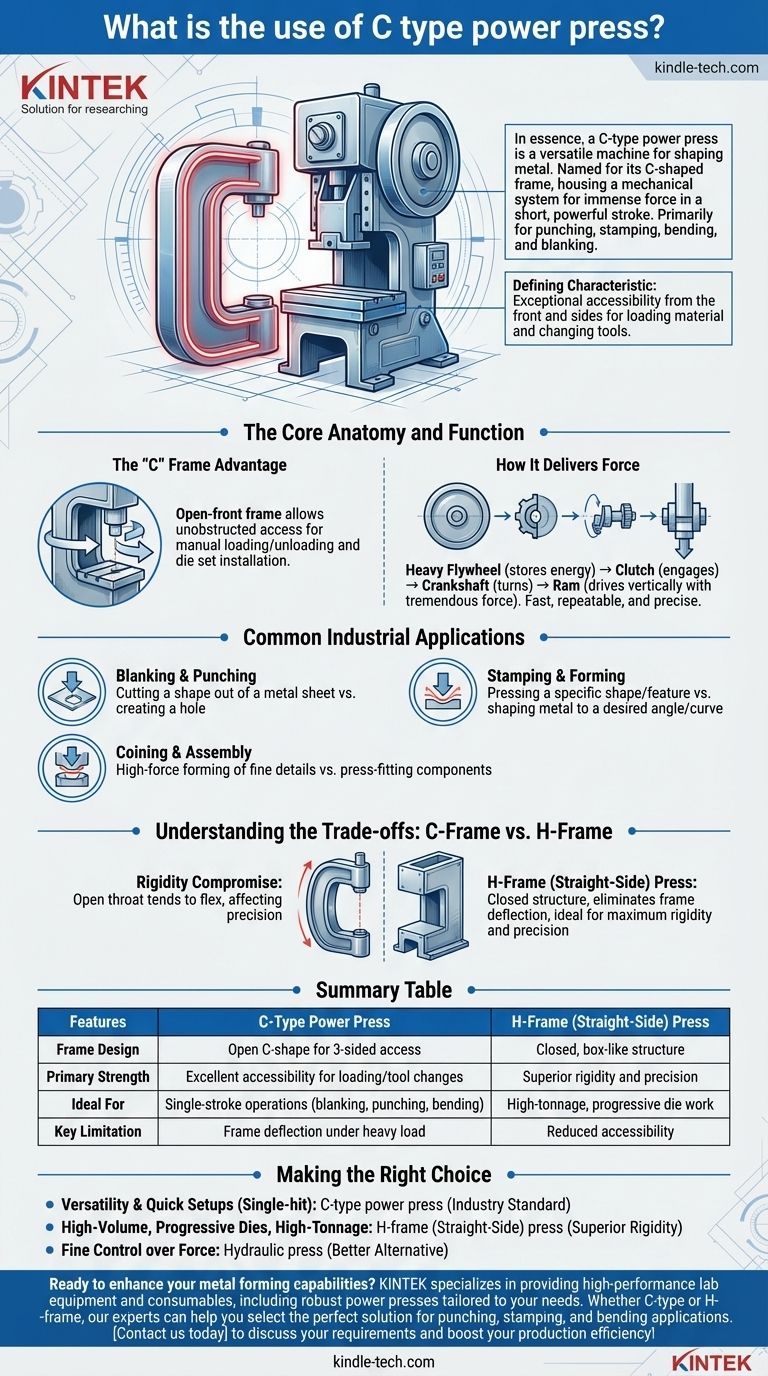

In essence, a C-type power press is a versatile and widely used machine for shaping metal and other materials. It gets its name from its C-shaped frame, which houses a mechanical system that uses a flywheel, clutch, and crankshaft to deliver immense force in a short, powerful stroke. This design is primarily used for operations like punching, stamping, bending, and blanking.

The defining characteristic of a C-type press is its frame design, which offers exceptional accessibility from the front and sides for loading material and changing tools. This advantage, however, introduces a critical trade-off in structural rigidity compared to other press designs.

The Core Anatomy and Function

A deep understanding of the C-type press begins with its fundamental design and mechanism. These factors dictate its applications, strengths, and limitations.

The "C" Frame Advantage

The most significant feature is the open-front frame. This C-shape provides operators with unobstructed access from three directions.

This design makes it exceptionally easy to manually load and unload workpieces, as well as to install and maintain the die sets used for forming.

How It Delivers Force

Unlike a hydraulic press that uses fluid pressure, a C-type power press is typically mechanical.

It stores rotational energy in a heavy flywheel. When activated, a clutch engages the flywheel, turning a crankshaft that drives a ram vertically with tremendous force. This action is fast, repeatable, and precise.

Common Industrial Applications

The C-type press is a fixture in machine shops and manufacturing plants due to its versatility. It excels at a wide range of single-stroke forming operations.

Blanking and Punching

Blanking is the process of cutting a shape out of a metal sheet, with the cut-out piece being the desired part.

Punching (or piercing) is the opposite, where the goal is to create a hole in the workpiece, and the cut-out material is scrap. The C-frame's accessibility makes it ideal for these common tasks.

Stamping and Forming

Stamping uses a die to press a specific shape or feature onto a workpiece, such as a logo or a structural rib.

Forming and bending use dies to shape the metal into a desired angle or curve, a fundamental process in creating brackets, enclosures, and other components.

Coining and Assembly

Coining is a high-force operation that creates fine details on a surface by causing the metal to flow into the die's cavities.

These presses are also used for assembly, such as press-fitting bearings, pins, or other components together with controlled force.

Understanding the Trade-offs: C-Frame vs. H-Frame

Choosing the right press means understanding its inherent limitations. The C-frame's greatest strength is also the source of its primary weakness.

The Rigidity Compromise

Under heavy load, the open "throat" of the C-frame has a tendency to flex or "yawn." This deflection can be microscopic but is critical.

This angular deflection can affect the precision of the final part and lead to uneven wear on expensive die sets, especially in high-tonnage applications.

When to Choose an H-Frame (Straight-Side) Press

For applications demanding maximum rigidity and precision, an H-frame (or straight-side) press is the superior choice.

Its closed, box-like structure with four-corner support eliminates frame deflection. This makes it the standard for high-tonnage stamping and complex progressive die operations where alignment is paramount. The trade-off is reduced accessibility.

Making the Right Choice for Your Application

Selecting the correct press is a critical decision based on the specific demands of the job.

- If your primary focus is versatility and quick setups for single-hit operations: The C-type power press is the industry standard due to its unmatched accessibility.

- If your primary focus is high-volume production with progressive dies or high-tonnage forming: The superior rigidity of an H-frame (straight-side) press is necessary to protect tooling and ensure part consistency.

- If your primary focus is fine control over force throughout a long stroke: A hydraulic press, which can also be built in a C-frame design, may be a better alternative to a mechanical power press.

Ultimately, understanding the C-frame's fundamental balance of accessibility against rigidity is the key to leveraging its power effectively in your production environment.

Summary Table:

| Feature | C-Type Power Press | H-Frame (Straight-Side) Press |

|---|---|---|

| Frame Design | Open C-shape for 3-sided access | Closed, box-like structure |

| Primary Strength | Excellent accessibility for loading/tool changes | Superior rigidity and precision |

| Ideal For | Single-stroke operations (blanking, punching, bending) | High-tonnage, progressive die work |

| Key Limitation | Frame deflection under heavy load | Reduced accessibility |

Ready to enhance your metal forming capabilities? KINTEK specializes in providing high-performance lab equipment and consumables, including robust power presses tailored to your laboratory and manufacturing needs. Whether you require the versatility of a C-type press or the precision of an H-frame model, our experts can help you select the perfect solution for punching, stamping, and bending applications. Contact us today to discuss your requirements and boost your production efficiency!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability