At its core, a rotary furnace is a specialized industrial oven used for the continuous, high-temperature processing of solids. Its primary function is to heat materials to extreme temperatures while constantly tumbling them, ensuring every particle is treated uniformly. This makes it essential for processes like high-temperature sintering, chemical reactions, and creating highly specialized optical components.

The defining feature of a rotary furnace is not just its ability to generate heat, but its use of rotation. This constant motion is the key to achieving unparalleled process uniformity, ensuring every part of the material is equally exposed to heat and reactive gases.

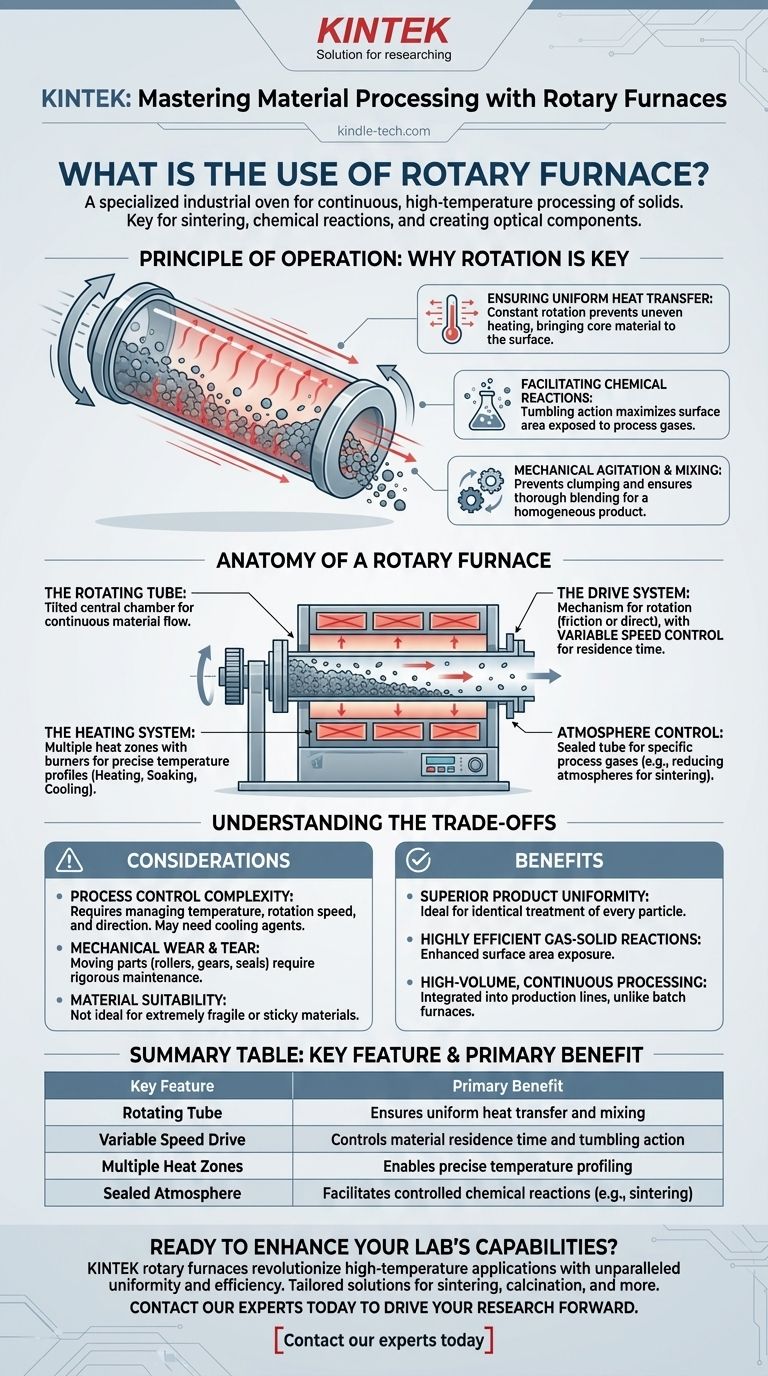

The Principle of Operation: Why Rotation is Key

The effectiveness of a rotary furnace stems directly from its cylindrical, rotating design. Unlike a static furnace where material sits motionless, the tumbling action is fundamental to the process.

Ensuring Uniform Heat Transfer

In a static environment, the material on the outside of a pile heats much faster than the material in the center. The constant rotation of a rotary furnace eliminates this problem by continuously bringing cooler material from the core to the surface, guaranteeing exceptionally even heat distribution.

Facilitating Chemical Reactions

Many industrial processes require a solid material to react with a gas. The furnace can be evacuated and filled with a specific atmosphere, such as a reducing gas. The tumbling action maximizes the surface area of the material exposed to the gas, dramatically increasing the speed and completeness of the chemical reaction.

Mechanical Agitation and Mixing

Rotation serves as a powerful mechanical mixer. It prevents materials from clumping or fusing together unevenly and ensures that different components of a mixture are thoroughly blended during the heating process, resulting in a homogenous final product.

Anatomy of a Rotary Furnace

A rotary furnace is a system of interconnected parts, each playing a critical role in controlling the thermal process.

The Rotating Tube

This is the central chamber where the material is processed. It is tilted at a slight angle to allow material to gradually move from the input end to the output end in a continuous flow.

The Drive System

The rotation is managed by a robust drive mechanism. This can be a friction drive where wheels spin the tube, or a more direct rack and pinion or chain drive for heavier loads. A variable speed drive is crucial for adjusting the rotation speed, which directly impacts how long the material stays in the furnace and how it tumbles.

The Heating System

Heat is typically applied through burners or nozzles that can fire fuel directly into the tube or heat the tube externally. These systems are often divided into multiple heat zones along the length of the furnace, allowing for a precise temperature profile to be programmed—heating, soaking, and cooling the material as it moves through.

Atmosphere Control

For advanced applications like sintering, the ability to control the internal atmosphere is vital. The furnace tube can be sealed, evacuated of air, and then filled with a specific process gas, creating the ideal chemical environment for the reaction.

Understanding the Trade-offs

While powerful, the rotary furnace design comes with specific considerations that are important for any technical evaluation.

Process Control Complexity

Temperature is not the only variable. Operators must also manage rotation speed and direction to control the process. In some applications, cooling agents like cold ash or other inert materials may be added to rapidly reduce the temperature if it overshoots, adding another layer of control.

Mechanical Wear and Tear

Because the furnace has many moving parts—including rollers, drive gears, and seals—it is subject to more mechanical wear than a static furnace. This necessitates a rigorous maintenance schedule to ensure reliability and prevent costly downtime.

Material Suitability

The tumbling action is not suitable for all materials. Extremely fragile components may be damaged by the constant motion, while very sticky or viscous materials may not flow properly through the tube.

Making the Right Choice for Your Goal

Selecting a rotary furnace is a decision driven by the specific demands of your thermal process.

- If your primary focus is product uniformity: A rotary furnace is the superior choice for ensuring every particle receives identical thermal and chemical treatment.

- If your primary focus is gas-solid reactions: The enhanced surface area exposure from tumbling makes a rotary furnace highly efficient for processes like ore reduction or calcination.

- If your primary focus is high-volume, continuous processing: The inherent design of a rotary furnace is ideal for integrating into a continuous production line, unlike batch-based static furnaces.

By understanding these core principles, you can determine if the unique capabilities of a rotary furnace align with your demanding material processing objectives.

Summary Table:

| Key Feature | Primary Benefit |

|---|---|

| Rotating Tube | Ensures uniform heat transfer and mixing |

| Variable Speed Drive | Controls material residence time and tumbling action |

| Multiple Heat Zones | Enables precise temperature profiling |

| Sealed Atmosphere | Facilitates controlled chemical reactions (e.g., sintering) |

Ready to enhance your lab's material processing capabilities?

A rotary furnace from KINTEK can revolutionize your high-temperature applications, ensuring unparalleled uniformity and efficiency for sintering, calcination, and chemical reactions. Our expertise in lab equipment means we provide solutions tailored to your specific needs, helping you achieve consistent, high-quality results.

Contact our experts today to discuss how a KINTEK rotary furnace can integrate into your workflow and drive your research and production forward.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the process of zirconium production? From Ore to High-Performance Metal & Ceramic

- What is a rotary retort furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- What is a rotary heat type furnace? The Ultimate Guide to Uniform Heating & Mixing

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas