It is critical to distinguish between two similar-sounding but distinct processes: Vacuum Arc Melting (VAM) and Vacuum Induction Melting (VIM). The process detailed here is Vacuum Induction Melting (VIM), a technique where metal is melted inside a vacuum chamber using electromagnetic induction, not an electric arc. This method is essential for producing high-purity, high-performance alloys that would be contaminated if melted in open air.

The fundamental purpose of Vacuum Induction Melting is to melt and refine reactive metals and specialty alloys in a controlled vacuum environment. This prevents contamination from atmospheric gases, removes dissolved impurities, and ensures a chemically uniform, high-quality final product.

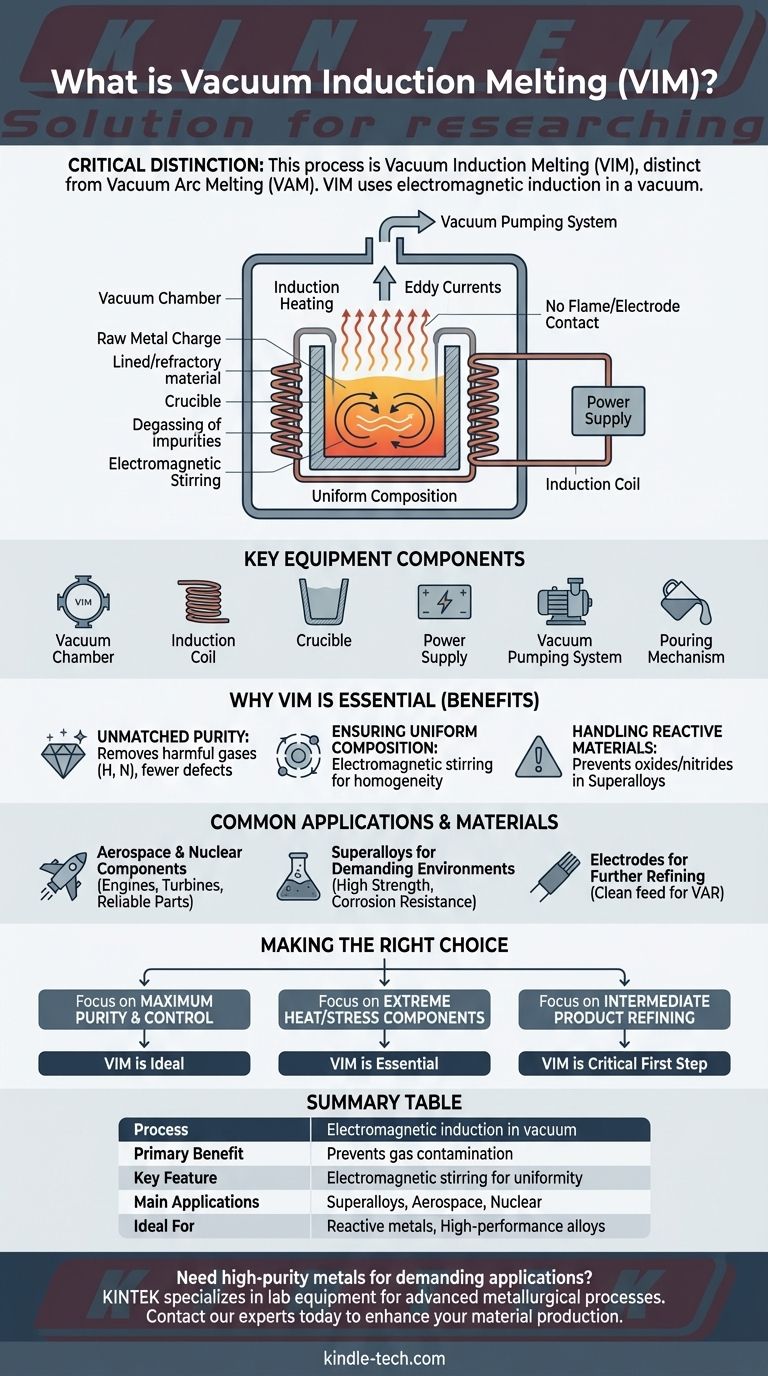

How Vacuum Induction Melting Works

The VIM process is a sophisticated method that relies on fundamental principles of physics and material science to achieve its results. It combines a clean energy source with a controlled atmosphere.

The Core Principle: Induction Heating

The raw solid metal is placed inside a crucible, which is a container lined with a refractory material. This crucible is enclosed by a powerful induction coil.

When a high-frequency alternating current flows through the coil, it generates a strong magnetic field. This field induces powerful electrical eddy currents within the metal itself. The metal's natural electrical resistance causes these currents to generate intense heat, melting the material from the inside out without any direct contact from a flame or electrode.

The Critical Role of the Vacuum

The entire process takes place inside a sealed, airtight chamber from which the air has been removed by a vacuum pumping system.

This vacuum environment is crucial because many advanced alloys, like superalloys, contain elements such as titanium and aluminum that readily react with oxygen and nitrogen in the air. Melting them in a vacuum prevents the formation of oxides and nitrides, which would compromise the material's integrity. The vacuum also helps pull dissolved gas impurities out of the molten metal.

Key Equipment Components

A VIM furnace is a complex system composed of several integrated parts:

- Vacuum Chamber: The airtight vessel containing the entire melting operation.

- Induction Coil: The water-cooled copper coil that generates the magnetic field.

- Crucible: The refractory-lined container that holds the metal charge.

- Power Supply: Provides the high-frequency current to the induction coil.

- Vacuum Pumping System: Removes air and other gases from the chamber.

- Pouring Mechanism: A system, often a crucible inversion mechanism, to pour the molten metal into molds for casting.

Why This Process is Essential

VIM is not just a melting method; it is a refining process used when the properties of the final material are paramount. Its benefits are directly tied to the controlled environment it creates.

Achieving Unmatched Purity

The vacuum environment is highly effective at degassing the molten metal. This removes harmful dissolved gases like hydrogen and nitrogen, leading to a cleaner, denser final product with fewer internal defects.

Ensuring Uniform Composition

A significant advantage of induction heating is the natural electromagnetic stirring it creates in the molten metal bath. This constant motion ensures that all alloying elements are distributed evenly, resulting in a perfectly homogenous composition and predictable, consistent material properties.

Handling Highly Reactive Materials

VIM is the go-to process for melting superalloys (based on nickel, cobalt, or iron) and other reactive metals. These materials are the backbone of high-performance applications and cannot be produced to the required quality standards using air-melting techniques.

Common Applications and Materials

The high quality of VIM products makes them indispensable in industries where material failure is not an option.

Superalloys for Demanding Environments

VIM is extensively used to produce superalloys that offer exceptional strength and corrosion resistance at extremely high temperatures.

Aerospace and Nuclear Components

These superalloys and other high-purity metals are cast into critical parts for aircraft engines, industrial gas turbines, and components for nuclear applications where reliability is an absolute necessity.

Electrodes for Further Refining

VIM is also used as a preliminary step to produce large, high-purity solid electrodes. These electrodes are then used in secondary melting processes, such as Vacuum Arc Remelting (VAR), for even further refinement.

Making the Right Choice for Your Goal

The decision to use a process like VIM is driven entirely by the required quality and performance of the final material.

- If your primary focus is maximum purity and precise chemical control: VIM is the ideal choice for eliminating gas contamination and achieving a homogenous alloy.

- If your primary focus is manufacturing components for extreme heat or stress: VIM is essential for producing the superalloys required for aerospace, defense, and power generation parts.

- If your primary focus is creating an intermediate product for further refinement: VIM is a critical first step in producing clean electrodes for secondary melting processes.

Ultimately, Vacuum Induction Melting is a foundational technology for creating the world's most advanced and reliable metal alloys.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Melts metal using electromagnetic induction in a vacuum chamber |

| Primary Benefit | Prevents contamination from atmospheric gases (oxygen, nitrogen) |

| Key Feature | Electromagnetic stirring ensures uniform alloy composition |

| Main Applications | Superalloys for aerospace, nuclear components, electrode production |

| Ideal For | Reactive metals (titanium, aluminum) and high-performance alloys |

Need high-purity metals for demanding applications? KINTEK specializes in lab equipment and consumables for advanced metallurgical processes. Our expertise in vacuum melting technology can help you achieve the material purity and consistency required for aerospace, nuclear, and high-performance industrial applications. Contact our experts today to discuss how our solutions can enhance your material production capabilities.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting