At its core, vacuum coating is a high-technology process for applying an exceptionally thin, high-performance film onto a surface within a vacuum chamber. Unlike painting, this method does not use a liquid carrier; instead, it deposits a coating material atom by atom to form a new, functional layer with properties like superior hardness, wear resistance, or specific optical characteristics. The entire process relies on creating a vacuum to eliminate all air and contaminants, ensuring the deposited layer is pure and strongly bonded to the substrate.

Vacuum coating isn't like painting; it's a manufacturing process that fundamentally transforms a component's surface at an atomic level. By vaporizing a material in a vacuum and depositing it onto a part, it creates ultra-thin, dense, and highly durable films that are impossible to achieve with conventional methods.

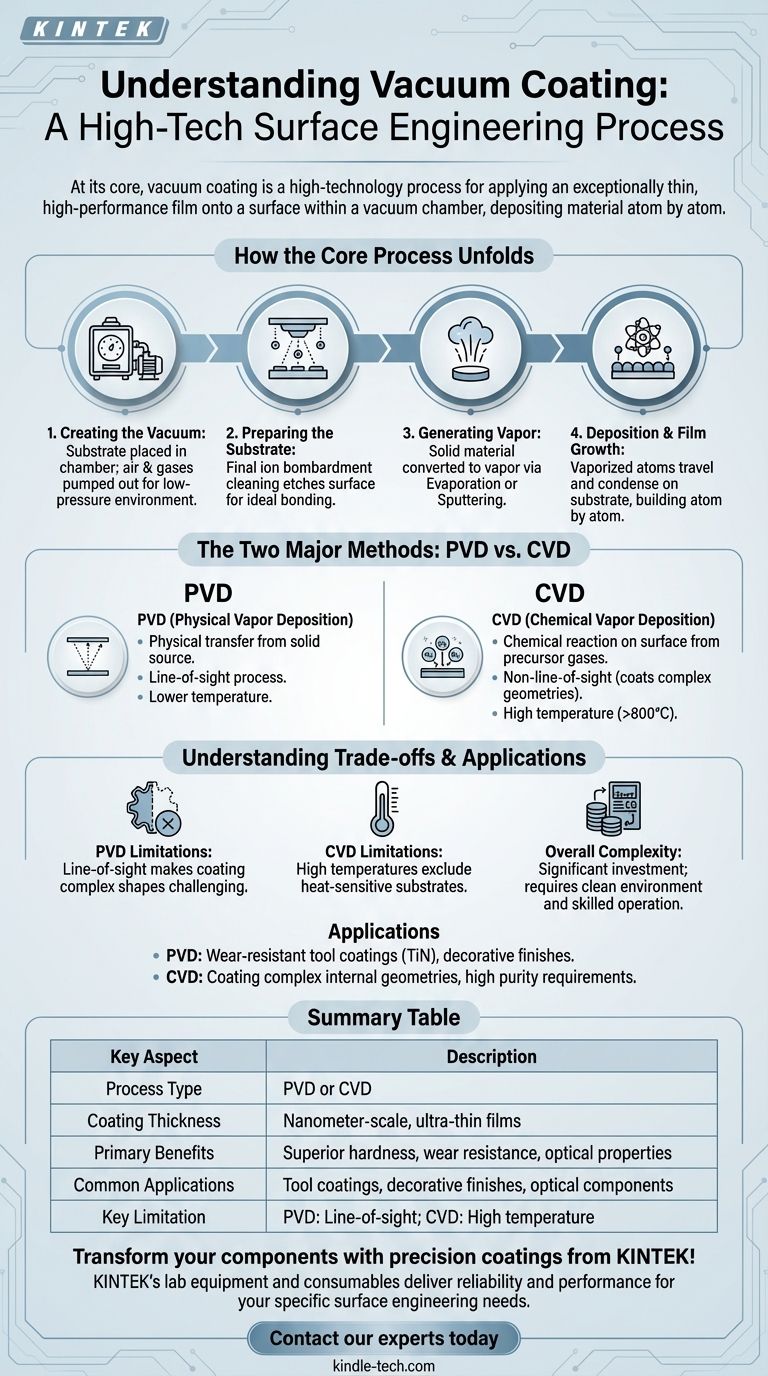

How the Core Process Unfolds

Vacuum coating, regardless of the specific type, follows a precise sequence of events. Each step is critical for ensuring the final film has the desired adhesion, purity, and performance.

Step 1: Creating the Vacuum

The component, or substrate, is placed inside a sealed chamber. All the air and other gases are then pumped out to create a low-pressure environment.

This vacuum is essential because it removes contaminants like oxygen, nitrogen, and water vapor that would otherwise react with the coating material and create a weak, impure film.

Step 2: Preparing the Substrate

Before deposition begins, the substrate often undergoes a final cleaning stage inside the vacuum, typically using an ion bombardment process.

This final cleaning etches the surface at a microscopic level, removing any residual oxides or impurities and creating an ideal foundation for the coating to bond to.

Step 3: Generating the Coating Material Vapor

A solid source material—often a metal or ceramic—is converted into a vapor. This is the key step that distinguishes different types of vacuum coating.

The two primary methods are evaporation (heating the material until it turns into a gas) or sputtering (bombarding the material with ions to knock atoms loose).

Step 4: Deposition and Film Growth

The vaporized coating atoms travel through the vacuum and strike the substrate. Upon impact, they condense and bond to the surface.

This deposition happens one atomic layer at a time, building a film that is extremely thin (often measured in nanometers), dense, and uniform. Reactive gases like nitrogen or oxygen can be introduced to create specific ceramic compounds like Titanium Nitride.

The Two Major Methods: PVD vs. CVD

While often used interchangeably, the term "vacuum coating" most commonly refers to Physical Vapor Deposition (PVD), but a related process, Chemical Vapor Deposition (CVD), also operates under similar principles. Understanding the difference is crucial.

Physical Vapor Deposition (PVD)

In PVD, the coating material is physically transferred from a solid source to the substrate. The material is vaporized through a physical process like heating or ion bombardment.

PVD is a "line of sight" process, meaning the coating only deposits on surfaces that have a direct path from the source material. It is a lower-temperature process, making it suitable for a wider range of substrate materials.

Chemical Vapor Deposition (CVD)

In CVD, the chamber is filled with one or more volatile precursor gases. The substrate is heated, which triggers a chemical reaction on its surface.

This reaction decomposes the gases, causing the desired material to deposit as a solid film while waste gases are pumped away. Because it relies on gas flow, CVD is not a line-of-sight process and can coat complex internal geometries more effectively.

Understanding the Trade-offs

Vacuum coating offers incredible benefits, but it is not without its limitations and complexities. Acknowledging these trade-offs is key to making an informed decision.

Line-of-Sight Limitations in PVD

Because most PVD processes are line-of-sight, coating complex shapes with internal passages or deep recesses is challenging. Parts often need to be rotated on complex fixtures to ensure even coverage.

High Temperatures in CVD

The chemical reactions in CVD typically require very high temperatures (often >800°C). This limits the process to substrates that can withstand this heat without being damaged, such as carbide tools, and excludes most steels and other temperature-sensitive materials.

Cost and Complexity

Vacuum deposition equipment represents a significant capital investment. The process requires a clean environment, skilled operators, and high energy consumption, making it more expensive per part than traditional coating methods like electroplating or painting.

Making the Right Choice for Your Application

Selecting the right vacuum coating process requires aligning the method's strengths with your primary goal.

- If your primary focus is maximizing hardness and wear resistance on metal tools: PVD coatings like Titanium Nitride (TiN) or Aluminum Titanium Nitride (AlTiN) are the industry standard due to their excellent performance and moderate process temperatures.

- If your primary focus is coating complex internal geometries or achieving supreme purity: CVD may be the superior choice, provided your substrate material can tolerate the very high process temperatures required.

- If your primary focus is applying a thin, decorative metallic finish: PVD sputtering is extremely effective for creating durable, brilliant finishes on everything from plastics and glass to consumer electronics and automotive trim.

By understanding these fundamental principles, you can confidently specify a surface engineering process that transforms a standard component into one that meets demanding performance goals.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) |

| Coating Thickness | Nanometer-scale, ultra-thin films |

| Primary Benefits | Superior hardness, wear resistance, optical properties |

| Common Applications | Tool coatings, decorative finishes, optical components |

| Key Limitation | PVD: Line-of-sight; CVD: High temperature requirements |

Transform your components with precision coatings from KINTEK!

Whether you need to enhance tool life with wear-resistant PVD coatings or achieve complex geometries with CVD, KINTEK's lab equipment and consumables deliver the reliability and performance your laboratory demands. Our expertise in vacuum coating solutions ensures you get the right surface engineering for your specific application.

Ready to elevate your manufacturing process? Contact our experts today to discuss how KINTEK can support your laboratory's coating needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures