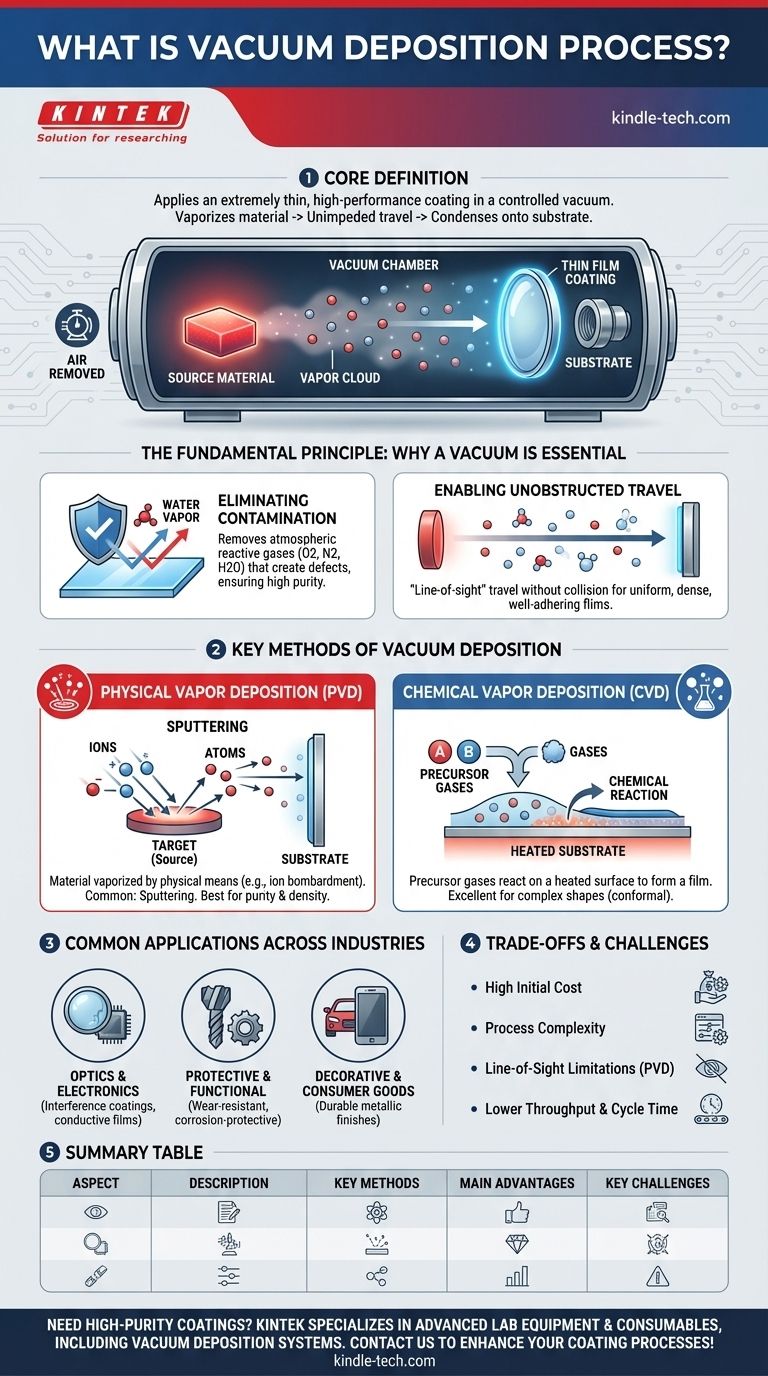

At its core, vacuum deposition is a family of processes used to apply an extremely thin, high-performance coating of material onto a surface, known as a substrate. This entire process takes place inside a highly controlled vacuum chamber. The vacuum is the critical element, as it removes air and other atmospheric gases that would otherwise contaminate or interfere with the coating, ensuring a pure, dense, and highly adherent film.

The central principle of vacuum deposition is converting a solid or liquid coating material into a vapor, allowing it to travel unimpeded through a vacuum, and then letting it condense onto a target object to form a thin film. This controlled environment is what enables the creation of coatings with precise optical, electrical, and protective properties that are impossible to achieve in open air.

The Fundamental Principle: Why a Vacuum is Essential

The use of a vacuum is not incidental; it is the defining characteristic that enables the entire process. Without it, the quality and function of the resulting films would be severely compromised.

Eliminating Contamination

Atmospheric air is filled with reactive gases like oxygen, nitrogen, and water vapor. These particles would react with the vaporized coating material, embedding impurities and creating defects in the final film.

A vacuum removes these contaminants, ensuring the deposited film is exceptionally pure.

Enabling Unobstructed Travel

In a vacuum, the vaporized coating atoms can travel in a straight line from their source to the substrate without colliding with air molecules.

This "line-of-sight" travel is crucial for creating uniform, dense, and well-adhering films. In normal air pressure, the atoms would scatter, resulting in a poor-quality, non-uniform coating.

Key Methods of Vacuum Deposition

Vacuum deposition is a broad category, not a single technique. The methods are primarily divided into two families based on how the material is vaporized.

Physical Vapor Deposition (PVD)

In PVD processes, the coating material is transformed into a vapor through purely physical means, such as heating or ion bombardment.

One of the most common PVD methods is sputtering. Here, a solid block of the coating material (the "target") is bombarded with high-energy ions, which knock atoms off its surface. These ejected atoms then travel through the vacuum and deposit onto the substrate.

Chemical Vapor Deposition (CVD)

In contrast to PVD, CVD involves introducing precursor gases into the vacuum chamber.

These gases undergo a chemical reaction directly on the heated substrate's surface, leaving behind a solid film of the desired material. This method is excellent for creating highly uniform (conformal) coatings over complex shapes.

Common Applications Across Industries

The precision and purity of vacuum-deposited films make them essential for countless high-tech and industrial products. The references highlight its wide-ranging use.

Optics and Electronics

This process is fundamental for creating optical interference coatings on lenses, mirror coatings, and electrically conducting films for semiconductor devices and solar cells.

Protective and Functional Coatings

Vacuum deposition is widely used to apply extremely hard, wear-resistant coatings on cutting tools and corrosion-protective coatings on components exposed to harsh environments.

Decorative and Consumer Goods

Many metallic finishes on consumer electronics, automotive trim, and even jewelry are created using vacuum deposition to apply a thin, durable, and decorative coating.

Understanding the Trade-offs and Challenges

While powerful, vacuum deposition is a complex and resource-intensive process with important considerations.

High Initial Cost

Vacuum chambers and their associated pumps, power supplies, and monitoring equipment represent a significant capital investment.

Process Complexity

Achieving a reproducible, high-quality product requires meticulous control over the process. As the references note, the design, operation, and maintenance of the chamber are essential for consistent results.

Line-of-Sight Limitations

Many PVD techniques are "line-of-sight" processes. This means they can struggle to evenly coat the interior surfaces or hidden areas of complex, three-dimensional parts.

Throughput and Cycle Time

Creating the vacuum, running the deposition cycle, and cooling the parts can be time-consuming. This can result in lower throughput compared to other, less precise coating methods like painting or electroplating.

Making the Right Choice for Your Goal

Selecting the appropriate coating strategy depends entirely on the required performance and properties of the final product.

- If your primary focus is maximum purity and density for a metallic or ceramic coating: A Physical Vapor Deposition (PVD) method like sputtering is often the superior choice.

- If your primary focus is applying a perfectly uniform coating over a complex 3D shape: Chemical Vapor Deposition (CVD) is likely better suited for the task.

- If your primary focus is balancing cost and performance for a protective or decorative finish: You must weigh the high upfront investment in vacuum equipment against the unparalleled quality and durability it provides.

Ultimately, vacuum deposition is the enabling technology behind the performance of many modern products, providing functionality that is simply unattainable by other means.

Summary Table:

| Aspect | Description |

|---|---|

| Core Principle | Coating material is vaporized in a vacuum and condenses on a substrate to form a thin film. |

| Key Methods | Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD). |

| Common Applications | Optical coatings, semiconductor devices, wear-resistant tool coatings, decorative finishes. |

| Main Advantages | High purity, dense films, precise control over properties, excellent adhesion. |

| Key Challenges | High initial cost, line-of-sight limitations, process complexity. |

Need high-purity coatings for your lab or production line? KINTEK specializes in advanced lab equipment and consumables, including vacuum deposition systems tailored to your specific needs. Whether you're in R&D or manufacturing, our solutions ensure precise, reliable coatings for optics, electronics, and protective applications. Contact us today to discuss how we can enhance your coating processes!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- What is electron beam coating? A Guide to High-Performance PVD Thin Films

- What is the principle of electron beam evaporation? A Guide to High-Purity Thin Film Deposition

- What thin films are deposited by electron beam evaporation? Unlock High-Performance Coatings

- How does electron beam curing work? Achieve Instant, Durable Curing for Industrial Applications

- What is an example of a physical vapor deposition? Discover Sputtering and Thermal Evaporation

- What is the purpose of an evaporator? The Key Component That Creates Cooling

- What were the 4 factors that affect the rate of evaporation? Master Control for Lab & Industrial Processes

- What is e-beam evaporation used for? Precision Coating for Optics, Aerospace & Electronics