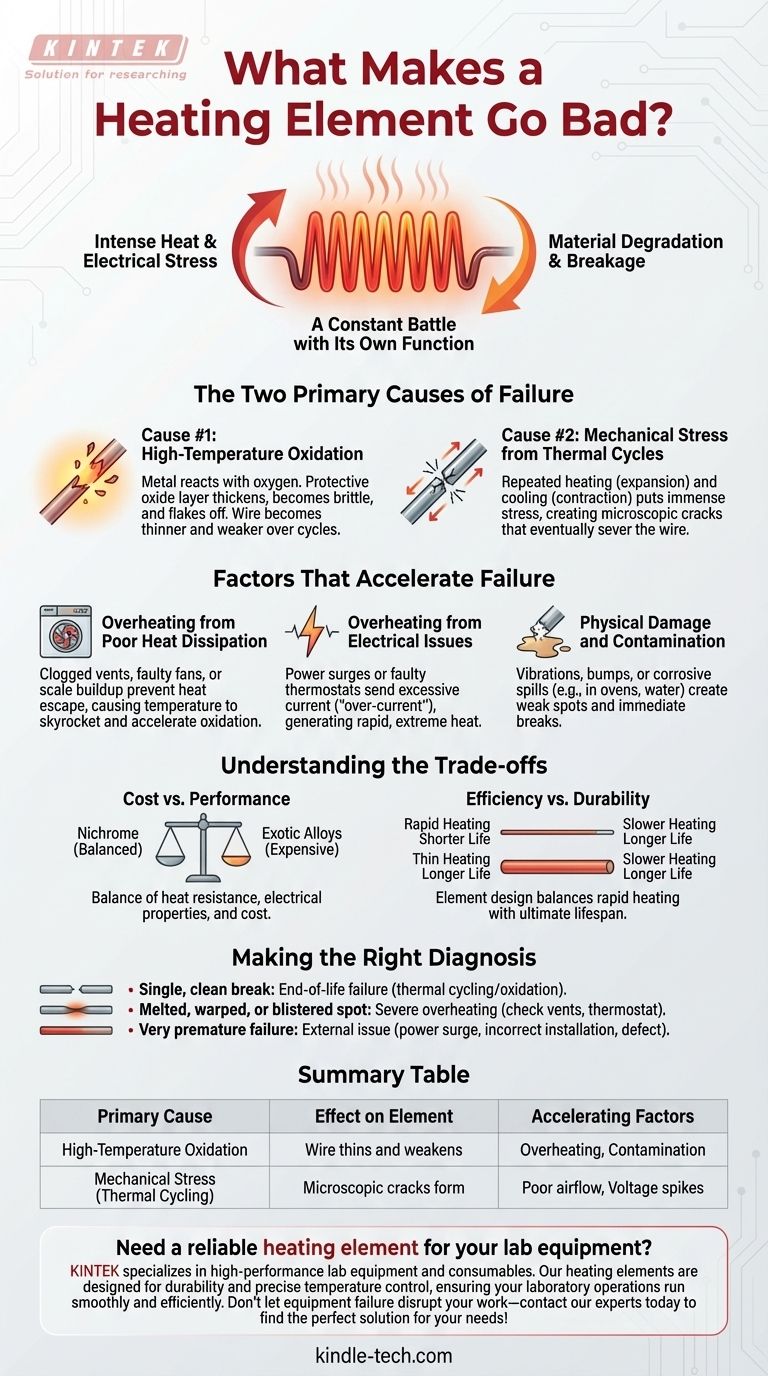

At its core, a heating element fails due to a combination of high-temperature corrosion and the physical stress of repeatedly expanding and contracting. The very job of getting intensely hot is what inevitably causes the material to degrade and break over time. This process is accelerated by factors like overheating from poor airflow or voltage spikes.

A heating element is in a constant battle with its own function. Its purpose is to generate extreme heat by resisting electricity, but this same heat and electrical stress slowly breaks down the metal wire until it can no longer complete the circuit.

The Two Primary Causes of Failure

A heating element is typically made from a special wire, like a nickel-chromium alloy (Nichrome), which is designed to handle high temperatures. However, even these robust materials have their limits.

Cause #1: High-Temperature Oxidation

When the element glows red hot, the metal is actively reacting with oxygen in the air. This process is called oxidation.

Initially, this forms a protective outer layer of oxide that prevents the core from burning through too quickly. Over many cycles, however, this layer thickens, becomes brittle, and can flake off, exposing fresh metal to oxidize again. Each cycle effectively makes the wire slightly thinner and weaker.

Cause #2: Mechanical Stress from Thermal Cycles

Every time you turn the appliance on, the element heats up and expands. When you turn it off, it cools down and contracts.

This constant cycle of expansion and contraction puts immense physical stress on the metal wire. Over thousands of cycles, this repeated stress creates microscopic cracks. Eventually, one of these cracks will grow large enough to sever the wire, creating an open circuit.

Factors That Accelerate Failure

While all elements will eventually fail from oxidation and thermal stress, certain conditions can drastically shorten their lifespan. These issues push the element beyond its designed operating limits.

Overheating from Poor Heat Dissipation

A heating element is designed to transfer its heat energy to something else—the air in a dryer, the water in a water heater, or the food in an oven.

If this heat cannot escape effectively, the element's temperature will skyrocket past its intended range. This dramatically accelerates oxidation and stress. Common causes include a clogged dryer vent, a faulty fan in a convection oven, or a thick layer of mineral scale on a water heater element.

Overheating from Electrical Issues

An element is designed for a specific voltage and current. A significant power surge or a fault in the appliance's thermostat can send excessive current through the wire.

This "over-current" condition generates far more heat than the element can handle, leading to a rapid burnout. It is the electrical equivalent of running a car engine constantly at its redline.

Physical Damage and Contamination

Vibrations, bumps, or shocks can damage an already brittle, hot element, causing an immediate break.

Furthermore, spills in an oven or contaminants in water can corrode the element's surface. This corrosion creates a weak spot that becomes the focal point for a future failure under normal heat and stress.

Understanding the Trade-offs

You might wonder why these components aren't simply built to last forever. The answer lies in a balance of physics and economics.

Cost vs. Performance

Manufacturers choose materials like Nichrome because they provide the best balance of heat resistance, electrical properties, and cost for consumer appliances. Using more exotic, longer-lasting alloys would significantly increase the price of the final product.

Efficiency vs. Durability

A thicker wire would be more durable and last longer. However, it would also take longer to heat up, consume more energy to reach temperature, and might not fit within the appliance's design. The element's design is a trade-off between rapid heating performance and its ultimate lifespan.

Making the Right Diagnosis

Understanding why an element fails helps you identify the root cause of the problem in your appliance.

- If you see a single, clean break in the wire: This is likely a standard end-of-life failure caused by long-term thermal cycling and oxidation.

- If you see a melted, warped, or blistered spot: This points to severe overheating, and you should investigate the cause, such as a blocked vent or a faulty thermostat.

- If the element failed very prematurely: Suspect an external issue like a major power surge, incorrect installation, or a manufacturing defect in the part.

By recognizing that a heating element's failure is an inevitable result of its function, you can better diagnose issues and appreciate the importance of maintenance in extending its life.

Summary Table:

| Primary Cause | Effect on Element | Accelerating Factors |

|---|---|---|

| High-Temperature Oxidation | Wire thins and weakens over time | Overheating, Contamination |

| Mechanical Stress (Thermal Cycling) | Microscopic cracks form and grow | Poor airflow, Voltage spikes |

Need a reliable heating element for your lab equipment?

KINTEK specializes in high-performance lab equipment and consumables. Our heating elements are designed for durability and precise temperature control, ensuring your laboratory operations run smoothly and efficiently. Don't let equipment failure disrupt your work—contact our experts today to find the perfect solution for your needs!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What is the thermal expansion coefficient of molybdenum disilicide? Understanding its role in high-temperature design

- What is the temperature range of molybdenum disilicide heating elements? Choose the Right Grade for Your High-Temp Needs

- What is the temperature range of a MoSi2 heating element? Unlock 1900°C Performance for Your Lab

- What are the heating elements for high temperature furnaces? Select the Right Element for Your Atmosphere

- What is molybdenum disilicide used for? Powering High-Temperature Furnaces Up to 1800°C