At their core, carbon nanotubes are unique because they combine exceptional mechanical strength, electrical conductivity, and thermal properties into a single, nanoscopic cylindrical structure. This makes them highly effective performance-enhancing additives in applications ranging from lithium-ion batteries to advanced composite materials.

The true advantage of carbon nanotubes lies not just in their individual properties, but in their ability to deliver superior performance with a comparatively lower environmental footprint than traditional alternatives like carbon black.

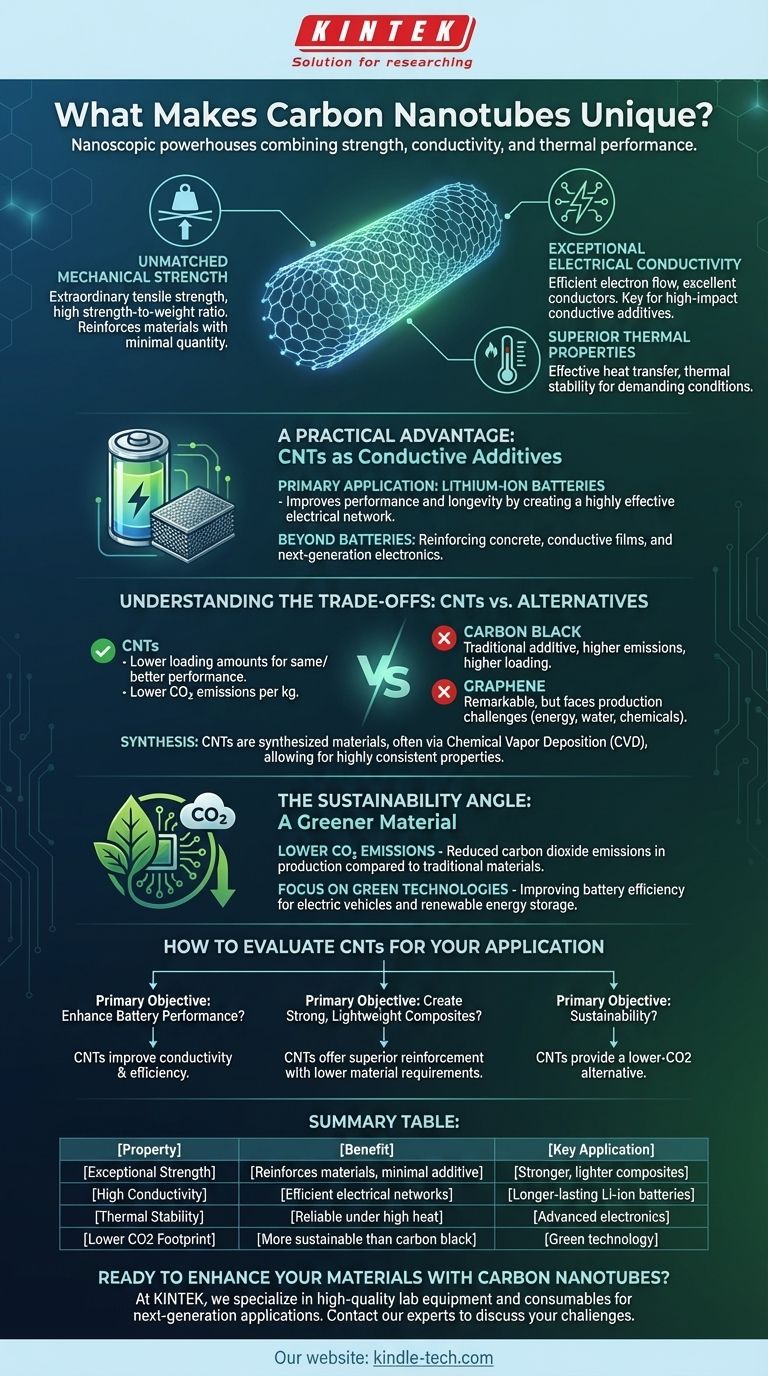

The Core Properties Defining Carbon Nanotubes

The unique, cylindrical arrangement of carbon atoms gives nanotubes a set of powerful characteristics that are difficult to find in a single material.

Unmatched Mechanical Strength

Carbon nanotubes possess extraordinary tensile strength and a high strength-to-weight ratio. This allows them to significantly reinforce materials even when added in very small quantities.

Exceptional Electrical Conductivity

Their structure allows for efficient electron flow, making them excellent electrical conductors. This property is the primary reason for their widespread use as conductive additives.

Superior Thermal Properties

In addition to their strength and conductivity, nanotubes can also effectively transfer heat. This thermal stability is critical for applications that operate under demanding conditions, such as high-performance electronics and batteries.

A Practical Advantage: CNTs as Conductive Additives

While their properties are impressive in theory, their uniqueness is most evident in their practical application as a high-impact additive.

The Primary Application: Lithium-Ion Batteries

The most significant use for carbon nanotubes today is as a conductive additive in lithium-ion batteries. They create a highly effective electrical network within the battery, improving performance and longevity.

Beyond Batteries: Broadening Horizons

Their versatility is expanding into other fields. Researchers and engineers are actively exploring CNTs for reinforcing concrete, creating conductive films, and developing next-generation electronics.

Understanding the Trade-offs: CNTs vs. Alternatives

To fully appreciate what makes carbon nanotubes unique, it is essential to compare them to other materials used for similar purposes.

The Comparison with Carbon Black

Compared to a traditional additive like carbon black, carbon nanotubes have a significant advantage. They require lower loading amounts to achieve the same or better performance and are produced with lower CO2 emissions per kilogram.

The Graphene Question

While graphene also has remarkable properties, its large-scale production often faces challenges. These can include issues with energy efficiency, high water usage, and the need for harsh chemicals, making CNTs a more practical choice for many current industrial applications.

Synthesis and Production

It's important to note that carbon nanotubes are synthesized materials, typically created using sophisticated techniques like Chemical Vapor Deposition (CVD). This controlled manufacturing process is what allows for their highly consistent and desirable properties.

The Sustainability Angle: A Greener Material

A key differentiator for carbon nanotubes in the modern market is their connection to environmental performance and green technology.

Lower CO2 Emissions

The production of carbon nanotubes generally results in lower carbon dioxide emissions when compared directly to incumbent materials like carbon black, offering a clear environmental benefit.

A Focus on Green Technologies

Much of the current interest and application of CNTs is in green technologies. Their role in improving battery efficiency directly contributes to the advancement of electric vehicles and renewable energy storage.

How to Evaluate Carbon nanotubes for Your Application

To determine if CNTs are the right choice, consider your primary objective.

- If your primary focus is enhancing battery performance: Carbon nanotubes are a proven solution for improving conductivity and efficiency.

- If your primary focus is creating strong, lightweight composites: CNTs offer superior reinforcement with lower material requirements than traditional fillers.

- If your primary focus is sustainability and environmental impact: CNTs provide a lower-CO2 alternative to materials like carbon black for conductive applications.

Ultimately, carbon nanotubes offer a unique and powerful tool for solving complex engineering challenges with efficiency and performance.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Exceptional Strength | Reinforces materials with minimal additive | Stronger, lighter composites |

| High Conductivity | Creates efficient electrical networks | Longer-lasting lithium-ion batteries |

| Thermal Stability | Performs reliably under high heat | Advanced electronics and materials |

| Lower CO2 Footprint | More sustainable than carbon black | Green technology and sustainable manufacturing |

Ready to enhance your materials with the unique properties of carbon nanotubes?

At KINTEK, we specialize in providing high-quality lab equipment and consumables for researchers and engineers developing next-generation applications. Whether you're working on advanced battery technology, stronger composites, or sustainable materials, our expertise can support your innovation.

Contact our experts today to discuss how carbon nanotubes can solve your specific challenges and unlock new levels of performance and efficiency in your projects.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Multi-zone Laboratory Tube Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the advantages of using the chemical Vapour deposition approach for CNT production? Scale Up with Cost-Effective Control

- What are the synthesis and purification methods for carbon nano tubes? Scaling Quality and Purity for Your Application

- What are sputtering targets for semiconductors? Essential High-Purity Materials for Thin Film Deposition

- Is deposition a chemical process? Understanding Chemical vs. Physical Thin-Film Methods

- What is the effect of thickness of thin film? Master Optical, Electrical, and Mechanical Properties

- What can carbon nanotubes be used for? Unlock Superior Performance in Batteries & Materials

- What are the properties of diamond coating? Unlock Extreme Performance for Your Components

- What are the characteristics of a coating produced by low-temperature arc vapor deposition (LTAVD)? Key Performance Insights