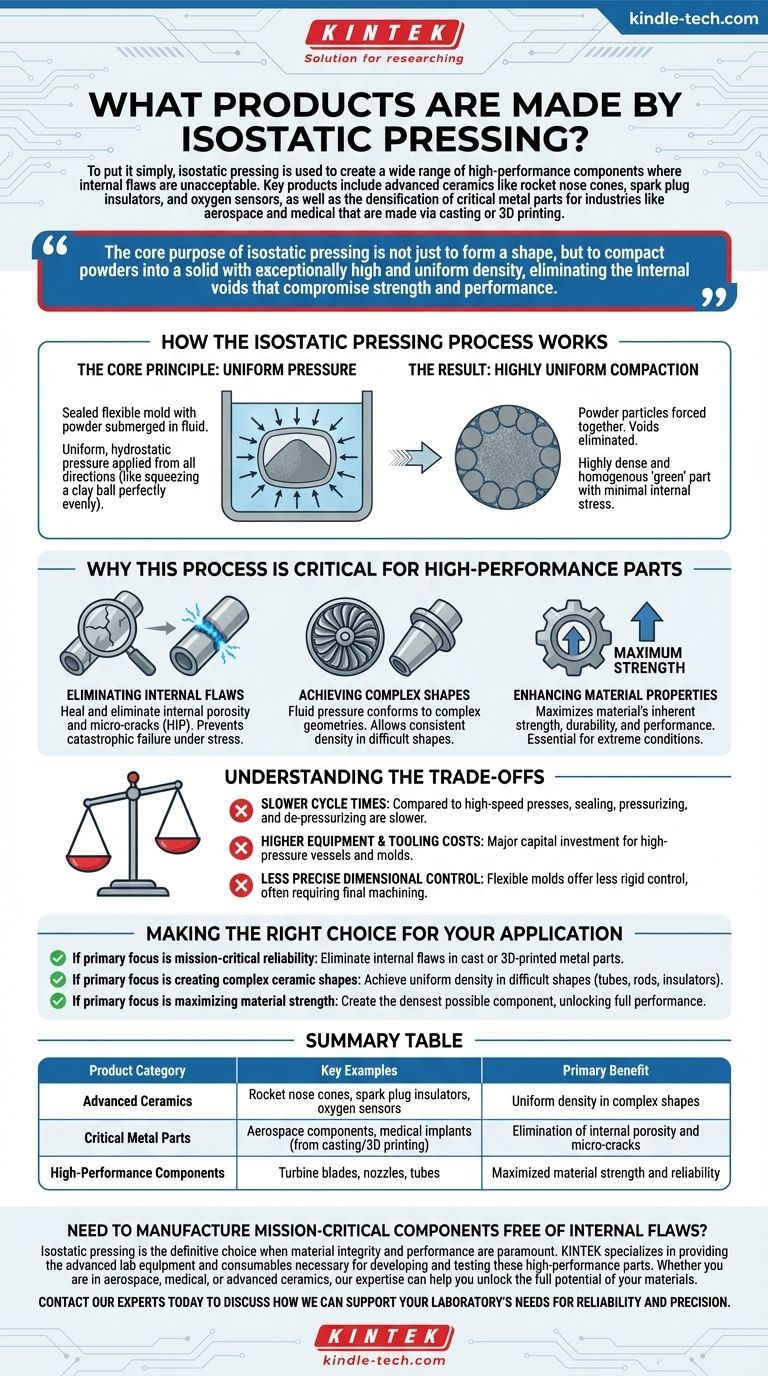

To put it simply, isostatic pressing is used to create a wide range of high-performance components where internal flaws are unacceptable. Key products include advanced ceramics like rocket nose cones, spark plug insulators, and oxygen sensors, as well as the densification of critical metal parts for industries like aerospace and medical that are made via casting or 3D printing.

The core purpose of isostatic pressing is not just to form a shape, but to compact powders into a solid with exceptionally high and uniform density, eliminating the internal voids that compromise strength and performance.

How the Isostatic Pressing Process Works

Isostatic pressing is fundamentally different from traditional pressing methods that apply force from one or two directions. Its unique approach is what makes it so valuable.

The Core Principle: Uniform Pressure

The process involves placing a powder into a sealed, flexible mold. This mold is then submerged in a fluid within a high-pressure chamber.

When the chamber is pressurized, the fluid exerts uniform, hydrostatic pressure on the mold from all directions simultaneously. It's like squeezing a ball of clay in your fist, but with perfectly even pressure on every point of the surface.

The Result: Highly Uniform Compaction

This all-around pressure is transmitted through the flexible mold to the powder inside.

The powder particles are forced together, eliminating voids and creating a highly dense and homogenous "green" part (an unfired or unsintered state) with minimal internal stress.

Why This Process is Critical for High-Performance Parts

The true value of isostatic pressing lies in the superior quality of the components it produces. It's chosen when the consequences of material failure are severe.

Eliminating Internal Flaws

For metal parts produced by casting, injection molding, or 3D printing, the process (specifically Hot Isostatic Pressing) is used to heal and eliminate internal porosity and micro-cracks.

These tiny, invisible flaws are starting points for catastrophic failure under stress. Isostatic pressing effectively welds them shut on a microscopic level.

Achieving Complex Shapes

Because the pressure is applied by a fluid, it can perfectly conform to complex geometries like nozzles, tubes, and other intricate shapes.

This allows for the creation of components that are difficult or impossible to form with consistent density using rigid, directional presses.

Enhancing Material Properties

By creating a nearly fully dense part, isostatic pressing maximizes the material's inherent strength, durability, and overall performance.

This is essential for components like medical implants, jet engine turbines, or ceramic insulators that must function reliably under extreme conditions.

Understanding the Trade-offs

While powerful, isostatic pressing is not a universal solution. Its benefits come with practical considerations that make it unsuitable for everyday, low-cost manufacturing.

Slower Cycle Times

Compared to automated, high-speed compaction presses, the process of sealing the mold, pressurizing the chamber, and safely de-pressurizing is significantly slower. This makes it less suitable for high-volume, low-cost parts.

Higher Equipment and Tooling Costs

The high-pressure vessels and complex systems required for isostatic pressing represent a major capital investment. Molds, while flexible, also contribute to the operational cost.

Less Precise Dimensional Control

While the density is highly uniform, the flexible mold does not offer the same rigid dimensional control as a hard steel die. Parts often require final machining or sintering to achieve their precise final dimensions.

Making the Right Choice for Your Application

Selecting this process depends entirely on the performance requirements of the final component.

- If your primary focus is mission-critical reliability: Specify isostatic pressing to eliminate internal flaws in cast or 3D-printed metal parts where failure is not an option.

- If your primary focus is creating complex ceramic shapes: Use isostatic pressing to achieve uniform density in parts like tubes, rods, and insulators that are difficult to form otherwise.

- If your primary focus is maximizing material strength: Employ this process to create the densest possible component from a powder, unlocking the full performance potential of the material.

Ultimately, isostatic pressing is the definitive choice when the integrity and uniformity of the material are more important than the cost or speed of production.

Summary Table:

| Product Category | Key Examples | Primary Benefit |

|---|---|---|

| Advanced Ceramics | Rocket nose cones, spark plug insulators, oxygen sensors | Uniform density in complex shapes |

| Critical Metal Parts | Aerospace components, medical implants (from casting/3D printing) | Elimination of internal porosity and micro-cracks |

| High-Performance Components | Turbine blades, nozzles, tubes | Maximized material strength and reliability |

Need to manufacture mission-critical components free of internal flaws?

Isostatic pressing is the definitive choice when material integrity and performance are paramount. KINTEK specializes in providing the advanced lab equipment and consumables necessary for developing and testing these high-performance parts.

Whether you are in aerospace, medical, or advanced ceramics, our expertise can help you unlock the full potential of your materials. Contact our experts today to discuss how we can support your laboratory's needs for reliability and precision.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is semi-isostatic pressing used for ceramics? Unlock Uniform Density and Superior Precision

- What is the use of cold isostatic pressing? Achieve Uniform Density for Superior Parts

- Why use cold pressing for Li10SnP2S12 electrolyte pellets? Preserving Stability in Sulfide Electrolytes

- How do isostatic presses work? Achieve Uniform Density with Isostatic Pressing

- What is the benefit of using a cold isostatic press for the secondary treatment of TiC10/Cu-Al2O3? Boost Density Now!

- What advantages does Cold Isostatic Pressing (CIP) offer for nickel-alumina composites? Enhance Density & Strength

- What is the difference between wet bag and dry bag isostatic pressing? Flexibility vs. High-Volume Production

- What is the cold CIP process? Achieve Uniform Density in Complex Powdered Parts