At its core, a hydraulic press is a machine for applying immense, controlled force. While its applications range from laboratory sample preparation to heavy industry, its primary function is to shape, deform, assemble, or crush materials through compression. It is used to manufacture everything from automotive body panels and aircraft parts to everyday items like kitchen sinks.

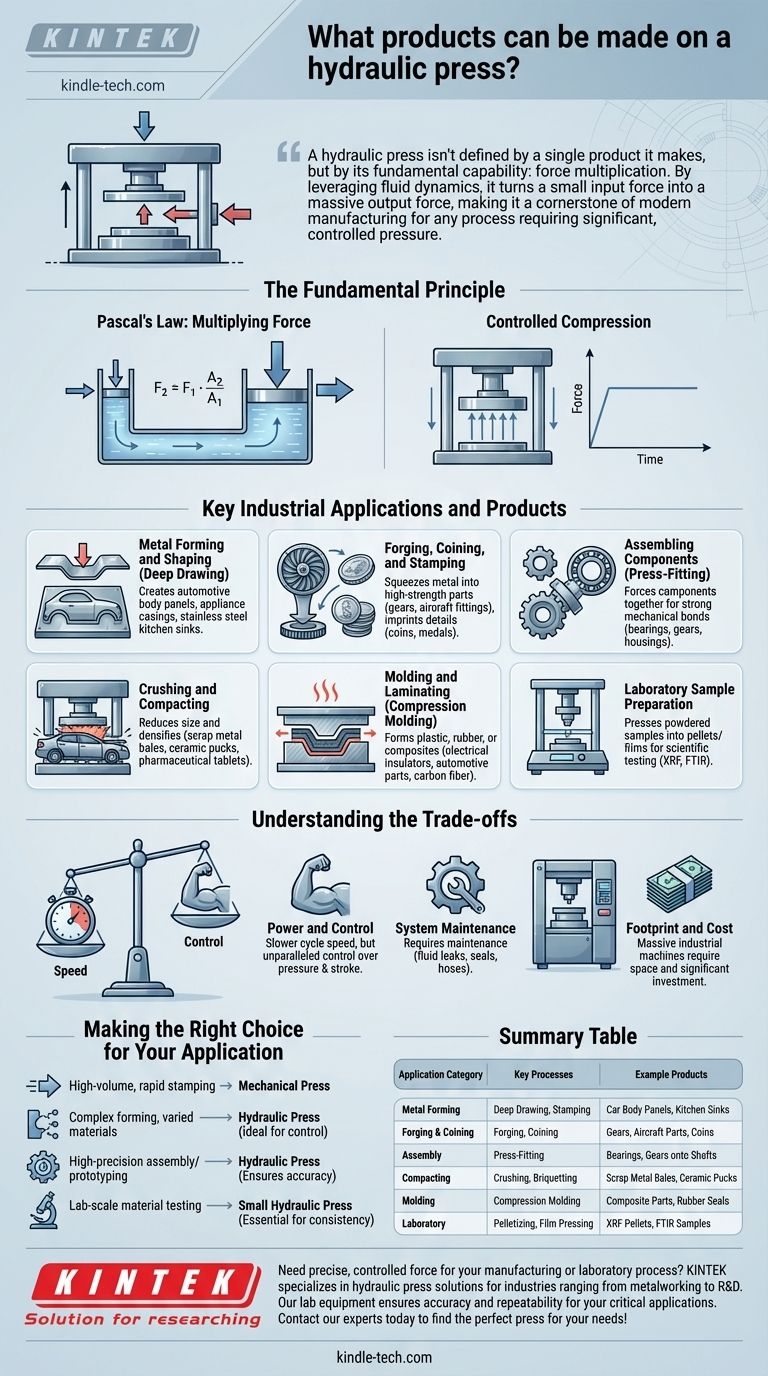

A hydraulic press isn't defined by a single product it makes, but by its fundamental capability: force multiplication. By leveraging fluid dynamics, it turns a small input force into a massive output force, making it a cornerstone of modern manufacturing for any process requiring significant, controlled pressure.

The Fundamental Principle: How a Hydraulic Press Works

To understand the vast applications of a hydraulic press, it's essential to grasp how it operates. The machine's versatility stems from a simple, elegant principle of physics.

Pascal's Law: Multiplying Force

A hydraulic press operates on Pascal's principle. This law states that pressure applied to an enclosed fluid is transmitted equally in all directions.

The press uses two interconnected cylinders of different sizes filled with hydraulic fluid. A small force is applied to a small piston (the plunger), creating pressure in the fluid. This same pressure then acts on a much larger piston (the ram), generating a proportionally larger output force.

The Core Function: Controlled Compression

The defining feature of a hydraulic press is its ability to deliver a constant, controllable compressive force throughout its entire stroke.

This slow, powerful, and even pressure is what allows it to perform complex shaping and forming operations that are difficult or impossible with other types of presses.

Key Industrial Applications and Products

The ability to deliver massive, controlled force makes the hydraulic press indispensable across numerous industries. Its applications go far beyond simple pressing.

Metal Forming and Shaping

This is one of the most common uses. The process, known as deep drawing, involves pressing a flat sheet of metal into a die to create complex, hollow shapes.

Products made this way include automotive body panels (doors, hoods), appliance casings, and stainless steel kitchen sinks.

Forging, Coining, and Stamping

In forging, a press is used to squeeze metal into high-strength parts like turbine blades, gears, and structural fittings for aircraft.

The high, even pressure is also perfect for coining, where intricate details are imprinted onto a metal surface, such as minting currency or medals.

Assembling Components

Hydraulic presses are widely used for press-fitting parts together. This involves forcing one component, like a bearing or gear, into or onto another component, like a housing or a shaft.

This creates a strong, reliable mechanical bond without the need for welding or fasteners.

Crushing and Compacting

The immense power of hydraulic presses is ideal for size reduction and densification. Large industrial presses are used to crush and bale scrap metal, including entire cars, for recycling.

They are also used to compact waste materials or press powders into solid forms, such as ceramic pucks or pharmaceutical tablets.

Molding and Laminating

In compression molding, a hydraulic press is used to form parts from materials like plastic, rubber, or composites. Heat and pressure are applied to the material inside a mold until it cures.

This process is used to create everything from electrical insulators and automotive parts to carbon fiber components.

Laboratory Sample Preparation

On a much smaller scale, benchtop hydraulic presses are essential tools in scientific and material testing labs.

As noted in technical specifications, they are used to press powdered samples into thin, solid pellets or films for analysis by techniques like X-ray fluorescence (XRF) or Fourier-transform infrared spectroscopy (FTIR).

Understanding the Trade-offs

While incredibly versatile, hydraulic presses are not the solution for every application. Understanding their limitations is key to using them effectively.

Speed vs. Power and Control

The primary trade-off is speed. Hydraulic presses are generally slower than their mechanical counterparts.

While they sacrifice cycle speed, they offer unparalleled control over pressure and stroke length, which is critical for complex forming operations or when working with sensitive materials.

System Maintenance

The design is simple in principle, but the hydraulic system itself requires maintenance. Hydraulic fluid can leak, and seals or hoses can wear out over time.

Proper maintenance is crucial to prevent downtime and ensure consistent, safe operation.

Footprint and Cost

While a small lab press is compact, industrial-scale presses capable of delivering thousands of tons of force are massive machines that require significant floor space and a substantial initial investment.

Making the Right Choice for Your Application

The decision to use a hydraulic press depends entirely on the specific requirements of the task at hand.

- If your primary focus is high-volume, rapid stamping of simple parts: A mechanical press is often the better choice due to its higher cycle speed.

- If your primary focus is forming complex, deep-drawn shapes or working with varied materials: The superior control and constant pressure of a hydraulic press make it the ideal solution.

- If your primary focus is assembling high-precision components or prototyping: The controlled force of a hydraulic press ensures accuracy and repeatability.

- If your primary focus is lab-scale material testing: A small, manual or automated hydraulic press is an essential tool for consistent sample preparation.

Ultimately, the hydraulic press is a foundational tool of engineering, valued for its simple power and profound versatility.

Summary Table:

| Application Category | Key Processes | Example Products |

|---|---|---|

| Metal Forming | Deep Drawing, Stamping | Car Body Panels, Kitchen Sinks |

| Forging & Coining | Forging, Coining | Gears, Aircraft Parts, Coins |

| Assembly | Press-Fitting | Bearings, Gears onto Shafts |

| Compacting | Crushing, Briquetting | Scrap Metal Bales, Ceramic Pucks |

| Molding | Compression Molding | Composite Parts, Rubber Seals |

| Laboratory | Pelletizing, Film Pressing | XRF Pellets, FTIR Samples |

Need precise, controlled force for your manufacturing or laboratory process? KINTEK specializes in hydraulic press solutions for industries ranging from metalworking to R&D. Our lab equipment, including presses for XRF sample preparation, ensures accuracy and repeatability for your critical applications. Contact our experts today to find the perfect press for your needs!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What role does a laboratory hydraulic press play in the assembly of all-solid-state lithium-sulfur batteries?

- How much does a small hydraulic press cost? Find the Right Tonnage for Your Budget

- What is the alternative to KBr in IR spectroscopy? Explore Faster, Easier Sample Prep Methods

- How does a laboratory hydraulic press prepare C-SiC-B4C-TiB2 powders? Enhance Your Composite Pre-Forming Success

- How do you use a KBr press? Master the Art of Creating Transparent Pellets for FTIR Analysis

- What is the purpose of applying a compression load in dissimilar alloy brazing? Ensure Defect-Free Joint Integrity

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab

- What is the effect of heat generated in hydraulic system? Prevent Costly Damage and Downtime