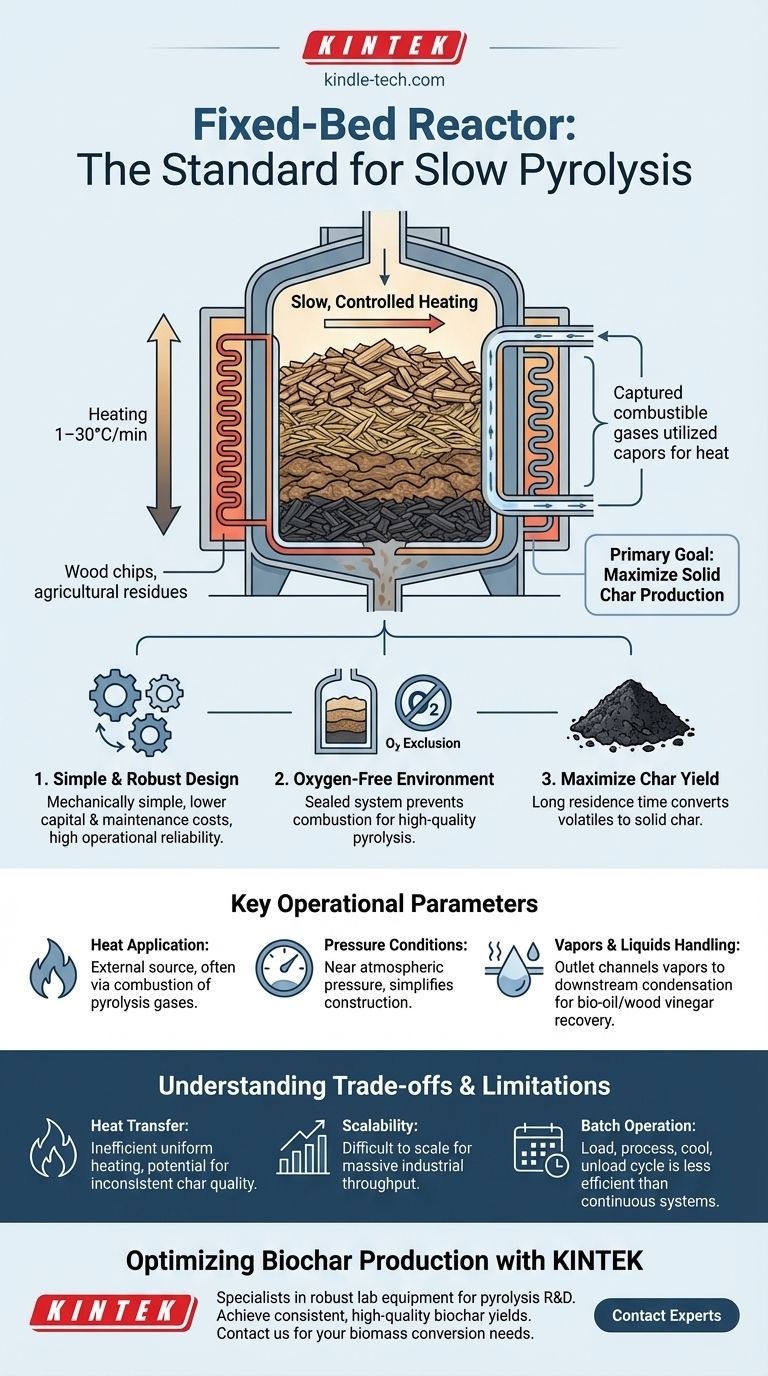

For slow pyrolysis, the most common and direct choice is the fixed-bed reactor. This design involves loading the biomass feedstock into a stationary chamber where heat is applied slowly and gradually. This approach perfectly aligns with the core requirements of slow pyrolysis: a low heating rate (typically 1–30°C per minute) and an oxygen-limited environment, designed specifically to maximize the production of solid char.

The choice of a fixed-bed reactor for slow pyrolysis isn't arbitrary; it's a design decision driven by the process's fundamental goal of maximizing solid char production through slow, controlled heating of a stationary biomass pile.

Why Fixed-Bed Reactors Dominate Slow Pyrolysis

The suitability of a fixed-bed reactor stems from its alignment with the slow, low-intensity nature of the process. Its design directly facilitates the necessary conditions for high-quality char production.

The Principle of Slow, Controlled Heating

Slow pyrolysis is defined by its gradual temperature increase. A fixed-bed design allows a static mass of feedstock to be heated thoroughly and evenly over a long period.

This long residence time is critical for the secondary reactions that convert volatile compounds into additional solid char, thereby maximizing the final yield.

Simple and Robust Design

Compared to more complex systems like fluidized-bed or ablative reactors used in fast pyrolysis, the fixed-bed reactor is mechanically simple.

There are fewer moving parts, which reduces capital costs, lowers maintenance requirements, and increases operational reliability, making it ideal for many wood and agricultural biomass applications.

Maintaining an Oxygen-Free Environment

Achieving high-quality pyrolysis products requires the near-total exclusion of oxygen to prevent combustion.

A sealed, stationary reactor chamber makes it significantly easier to control the internal atmosphere, purge it with inert gas if necessary, and prevent air from leaking into the system.

Key Operational Parameters of the Reactor System

While the reactor type is central, the overall system's success depends on managing several key operational factors that influence the process.

Method of Heat Application

Heat is typically supplied from an external source. The reactor must be designed to transfer this energy effectively into the stationary pile of biomass, which is often a poor thermal conductor.

Common methods include heating the reactor walls or using internal heat exchange tubes. In many systems, the combustible gases produced during pyrolysis are captured and burned to provide this process heat, creating a more self-sustaining operation.

Pressure Conditions

Slow pyrolysis is almost always conducted at or near atmospheric pressure. This simplifies the reactor's construction, as it does not need to be a high-pressure vessel, further contributing to lower costs and enhanced safety.

Handling Vapors and Liquids

While solid char is the primary product, the process also generates vapors. The reactor must have an outlet to channel these vapors to a downstream condensation system.

This system captures the liquid products, often called wood vinegar or bio-oil. Because slow pyrolysis yields less liquid than fast pyrolysis, these condensation and collection systems can be designed more simply.

Understanding the Trade-offs

While effective, the fixed-bed reactor is not without its limitations. Understanding these trade-offs is crucial for proper application and scaling.

Heat Transfer Limitations

The primary drawback of a static bed is inefficient heat transfer. It can be difficult to heat a large volume of biomass uniformly, potentially leading to inconsistent char quality throughout the batch. The core may be under-processed while the edges are over-processed.

Scalability Challenges

Due to these heat transfer issues, traditional fixed-bed reactors can be difficult to scale to very large industrial capacities. For massive throughput, other designs like rotary kilns, which tumble the material to improve heat distribution, may become more viable despite their complexity.

Batch vs. Continuous Operation

Many fixed-bed reactors operate in a batch mode: load feedstock, run the process, cool down, and unload the char. This cycle can be time-consuming and less efficient from a throughput perspective compared to continuous reactor systems.

Making the Right Choice for Your Goal

The ideal reactor configuration depends directly on your primary product and intended operational scale.

- If your primary focus is maximizing solid biochar yield on a small-to-medium scale: A fixed-bed reactor is the most direct, reliable, and cost-effective solution.

- If your primary focus is producing liquid bio-oil or operating at a very large, continuous industrial scale: You may need to evaluate alternative reactor designs that prioritize rapid heat transfer and material movement.

Ultimately, understanding the core principles of slow pyrolysis—gradual heating and long residence times—is the key to selecting and operating the right reactor for your needs.

Summary Table:

| Feature | Fixed-Bed Reactor for Slow Pyrolysis |

|---|---|

| Primary Goal | Maximize solid biochar yield |

| Heating Rate | Low (1–30°C per minute) |

| Key Advantage | Simple, robust, and cost-effective design |

| Operation Mode | Typically batch |

| Best For | Small-to-medium scale biochar production |

Ready to optimize your biochar production process?

At KINTEK, we specialize in providing robust and reliable lab equipment for pyrolysis research and development. Whether you're scaling up from the lab or optimizing your process parameters, our expertise in reactor systems can help you achieve consistent, high-quality biochar yields.

Let's discuss your project. Contact our experts today to find the perfect solution for your laboratory's biomass conversion needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy