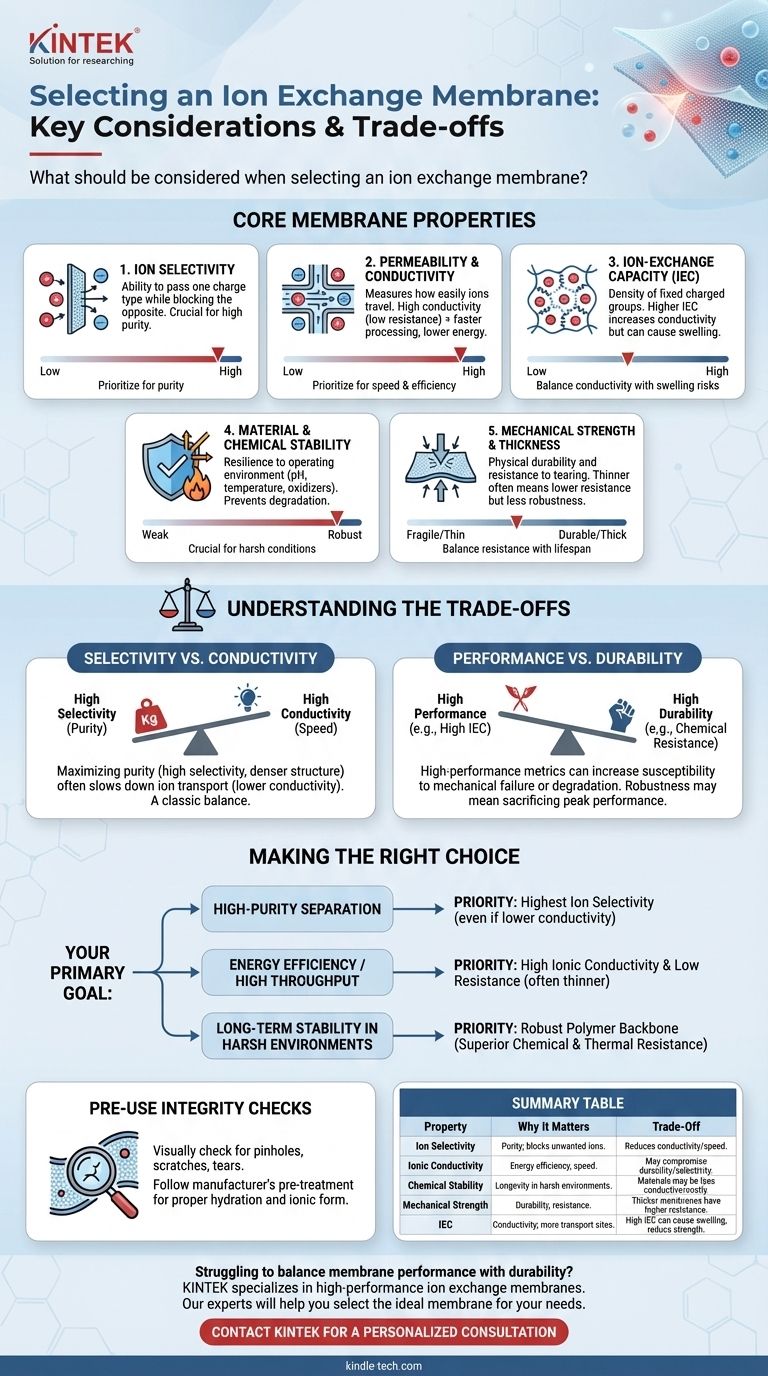

To select the right ion exchange membrane, you must evaluate its core properties in the context of your specific goal. The key factors to consider are the membrane's ion selectivity, permeability (or ionic conductivity), ion-exchange capacity, chemical stability, and physical characteristics like thickness and mechanical strength.

The central challenge in selecting an ion exchange membrane is not finding the "best" one, but understanding that every choice is a trade-off. You are balancing performance metrics like purity (selectivity) and speed (conductivity) against practical constraints like durability, chemical resistance, and cost.

Core Membrane Properties Explained

Understanding how each property influences the outcome is the first step toward making an informed decision. These factors are interconnected and must be evaluated together.

Ion Selectivity

Selectivity is a membrane's ability to allow ions of one charge (e.g., cations) to pass through while blocking ions of the opposite charge (e.g., anions).

This is the most fundamental property for separation tasks. High selectivity is crucial for applications requiring high-purity products or efficient separation of specific ions from a mixed solution.

Permeability & Ionic Conductivity

Permeability, often discussed in terms of ionic conductivity or area resistance, measures how easily the target ions can travel through the membrane.

A membrane with high ionic conductivity (low resistance) allows for faster processing rates and lower energy consumption. This is a critical factor for optimizing the efficiency and operating cost of any industrial-scale process.

Ion-Exchange Capacity (IEC)

IEC quantifies the density of fixed charged groups within the membrane polymer. It is typically measured in milliequivalents per gram of dry polymer.

A higher IEC generally leads to higher ionic conductivity but can also cause the membrane to swell more in water. Excessive swelling can negatively impact its mechanical strength and selectivity.

Material & Chemical Stability

The membrane's polymer backbone dictates its resilience. It must withstand the operating environment, which could include aggressive pH levels, oxidizing agents, or high temperatures.

Choosing a membrane made from a material incompatible with your solution will lead to rapid degradation, compromising the entire process and causing costly downtime.

Mechanical Strength & Thickness

This refers to the membrane's physical durability and its ability to resist tearing or puncture during handling and operation.

Thinner membranes typically offer lower electrical resistance (which is good for efficiency), but they are also more fragile. You must balance the need for low resistance with the requirement for a long operational lifespan.

Understanding the Trade-offs

There is no universally perfect membrane. Your selection will always involve balancing competing priorities.

Selectivity vs. Conductivity

Often, the most highly selective membranes have a denser structure, which can increase electrical resistance and slow down the transport of ions.

This creates a classic trade-off: maximizing purity (high selectivity) might come at the cost of processing speed and energy efficiency (lower conductivity).

Performance vs. Durability

High-performance membranes, such as those with very high IEC or extreme thinness, can sometimes be more susceptible to mechanical failure or chemical degradation.

A robust, chemically resistant membrane might offer a longer service life but may not provide the absolute highest level of conductivity.

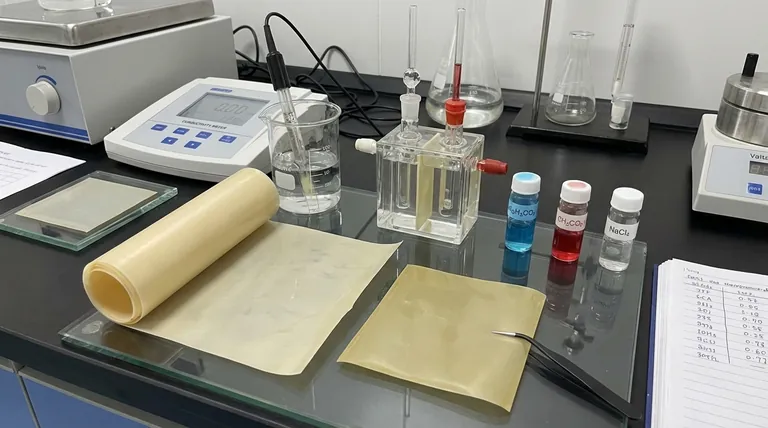

Pre-Use Integrity Checks

Before any use, a membrane must be inspected. A small, undetected flaw can render an experiment or process run invalid.

Visually check for any pinholes, scratches, or tears. It is also critical to follow the manufacturer's pre-treatment and conditioning protocols to ensure the membrane is properly hydrated and in the correct ionic form for use.

Making the Right Choice for Your Application

Your final decision should be dictated by the primary goal of your work.

- If your primary focus is high-purity separation: Prioritize membranes with the highest possible ion selectivity, even if it means slightly lower conductivity.

- If your primary focus is energy efficiency or high throughput: Select a membrane with high ionic conductivity and low electrical resistance, which often points to a thinner material.

- If your primary focus is long-term stability in harsh environments: Choose a membrane with a robust polymer backbone known for its superior chemical and thermal resistance.

Ultimately, the optimal ion exchange membrane is the one whose properties align precisely with the demands of your application.

Summary Table:

| Property | Why It Matters | Trade-Off |

|---|---|---|

| Ion Selectivity | Determines purity of separation; blocks unwanted ions. | Higher selectivity may reduce conductivity/speed. |

| Ionic Conductivity | Impacts energy efficiency and processing speed. | Higher conductivity may compromise durability or selectivity. |

| Chemical Stability | Ensures longevity in harsh environments (e.g., extreme pH, temperature). | Robust materials may be less conductive or more expensive. |

| Mechanical Strength | Affects durability and resistance to tearing/puncture. | Thicker, stronger membranes may have higher electrical resistance. |

| Ion-Exchange Capacity (IEC) | Influences conductivity; higher IEC = more ion transport sites. | High IEC can cause swelling, reducing mechanical strength. |

Struggling to balance membrane performance with durability? KINTEK specializes in lab equipment and consumables, including high-performance ion exchange membranes tailored for laboratory and industrial applications. Our experts will help you select the ideal membrane for your specific needs—ensuring optimal purity, efficiency, and longevity. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Anion Exchange Membrane for Laboratory Use

- Proton Exchange Membrane for Batteries Lab Applications

- Polyethylene Separator for Lithium Battery

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does an anion exchange membrane play in a PEC battery? Ensure Safe, High-Purity Hydrogen Production

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy

- How do ion-exchange membranes prevent H2O2 decomposition? Boost Yield and Efficiency in Flow Cells

- What is the purpose of an anion exchange membrane (AEM) or PEM? Enhance Electrochemical Efficiency

- What is the primary function of a Cation Exchange Membrane? Optimize Cu-Cl Cycle Efficiency and Longevity