Pellet mill die size is not a single number, but rather a set of critical dimensions that determine the final pellet's characteristics. The most important of these are the hole diameter, which sets the width of the pellet, and the total thickness of the die, which dictates the amount of compression the material undergoes. The right combination is chosen based on the raw material being processed and the desired quality of the final product.

The core takeaway is that selecting the right die is less about its individual dimensions and more about the relationship between them. The ratio of a die hole's length to its diameter is the most critical factor influencing pellet density, durability, and production efficiency.

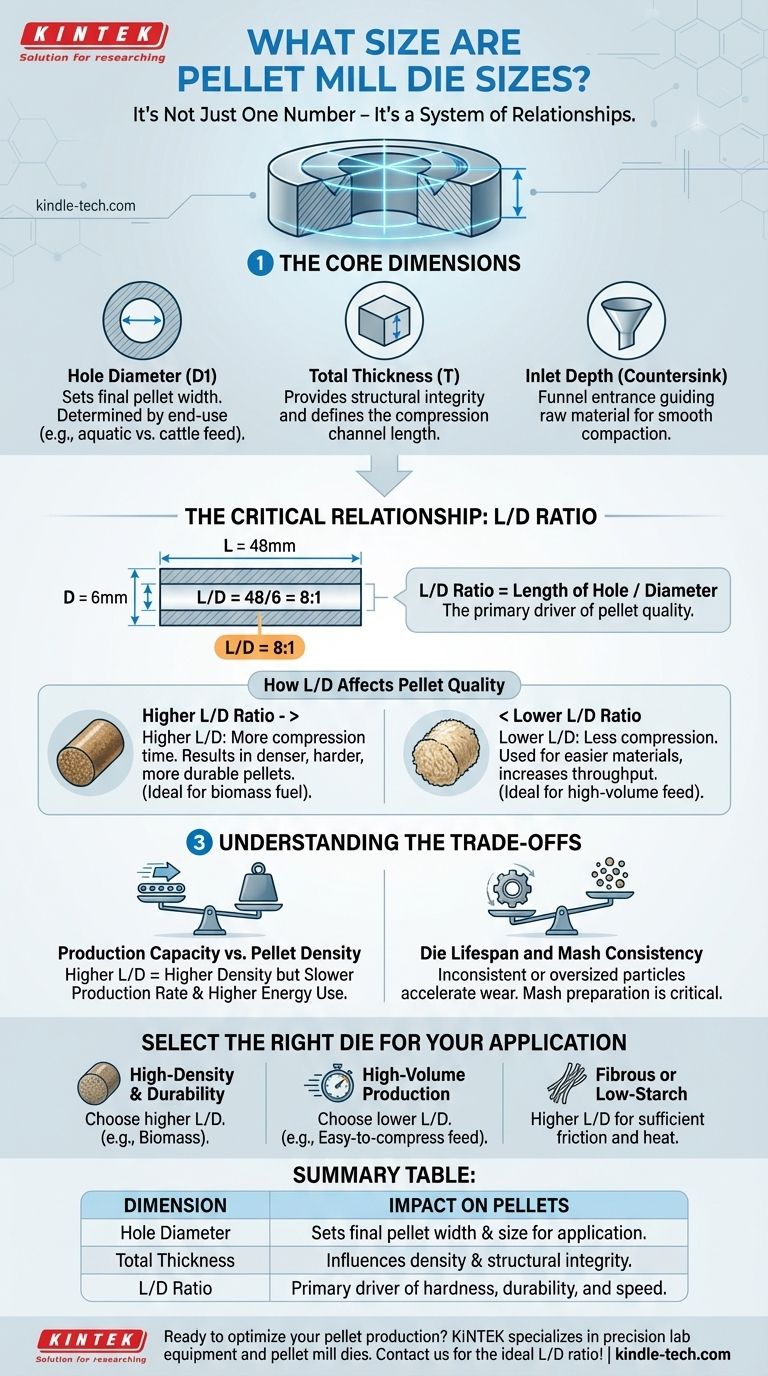

The Core Dimensions of a Pellet Mill Die

To understand how a die works, you must first understand its fundamental measurements. Each dimension serves a specific purpose in transforming loose mash into a compacted pellet.

Hole Diameter (D1)

This is the most straightforward dimension. The hole diameter directly determines the final diameter of the pellet produced.

This size is chosen based on the end-use. For example, animal feed varies widely, with smaller diameters required for aquatic feed and much larger diameters for cattle or horse feed.

Total Thickness (T)

The total thickness of the die provides the necessary structural integrity to withstand the immense pressure of the pelletizing process and prevent breakage.

However, its more important function is creating the channel where compression occurs. The length of this channel is what dictates how long the material is under pressure.

Inlet Depth (Countersink)

The inlet depth refers to the conical or tapered entrance to each hole on the die's surface.

This acts as a funnel, guiding the raw material from the die's surface into the compression channel smoothly, which is the first step in the compaction process.

Why the Relationship Between Dimensions Matters Most

Simply knowing the individual dimensions is not enough. The true art and science of pelleting lie in understanding how these dimensions work together, a concept defined by the length-to-diameter ratio.

The Critical L/D Ratio

The most important metric in die selection is the L/D ratio, or the ratio of the effective length of the hole (L) to its diameter (D).

A die with a 6mm hole diameter and a 48mm effective thickness has an L/D ratio of 8:1 (48/6). This ratio, not the thickness alone, is the primary driver of pellet quality.

How L/D Affects Pellet Quality

A higher L/D ratio means the material spends more time under compression within the die. This generates more heat and pressure, typically resulting in denser, harder, and more durable pellets.

Conversely, a lower L/D ratio is used for materials that are easier to compress or when extremely high density is not the primary goal.

Understanding the Trade-offs

Selecting a die is a balancing act between quality, production speed, and operational costs. Understanding the inherent trade-offs is key to making an informed decision.

Production Capacity vs. Pellet Density

A die with a high L/D ratio creates more resistance, which can slow down the rate of production (fewer tons per hour) and increase the energy consumption of the pellet mill.

You must balance the need for high-quality, dense pellets against the need for efficient, high-volume output.

Die Lifespan and Mash Consistency

The particle size of the raw material, or mash, has a direct impact on the life of a die. Inconsistent or oversized particles create uneven pressure points, leading to accelerated wear and even die failure.

A high-quality die can be quickly ruined by poorly prepared raw material, making mash preparation a critical factor in operational efficiency.

How to Select the Right Die for Your Application

Your choice should always be guided by your raw material and your final product goals.

- If your primary focus is high-density, durable pellets (e.g., for biomass fuel): Choose a die with a higher L/D ratio to maximize compression time and create a harder pellet.

- If your primary focus is high-volume production for easily compressed feed: A die with a lower L/D ratio can increase throughput and reduce energy costs without sacrificing necessary quality.

- If you are processing fibrous or low-starch materials: You may need a higher L/D ratio to generate enough friction and heat to bind the pellets properly.

Ultimately, mastering pellet production comes from understanding that the die is not just a part, but a precise tool engineered for a specific material and outcome.

Summary Table:

| Dimension | Description | Impact on Pellets |

|---|---|---|

| Hole Diameter | Sets the final pellet width | Determines pellet size for specific applications (e.g., aquatic vs. cattle feed) |

| Total Thickness | Defines compression channel length | Influences pellet density and structural integrity |

| L/D Ratio | Ratio of hole length to diameter | Primary driver of pellet hardness, durability, and production speed |

Ready to optimize your pellet production? The right die is critical for achieving high-density, durable pellets while maximizing efficiency. At KINTEK, we specialize in precision lab equipment and consumables, including pellet mill dies tailored to your raw material and output goals. Our experts will help you select the ideal L/D ratio for superior results. Contact us today to discuss your specific needs and elevate your pelleting process!

Visual Guide

Related Products

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use

- Special Heat Press Mold for Lab Use

- Cylindrical Press Mold for Lab Applications

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

People Also Ask

- What does a tablet punching machine consist of? Core Components for Efficient Tablet Production

- How does a flat die pellet mill work? A Complete Guide to Small-Scale Pellet Production

- What are the advantages of tablet press machine? Achieve High-Speed, Consistent Production

- What is the use of single punch tablet press? For Precise R&D and Small-Batch Tablet Production

- What are the two classifications of press machines? Single Punch vs. Rotary Presses Explained

- What are advantages of single punch tablet press machine? Maximize R&D Efficiency with Minimal Material

- What are the advantages of a rotary tablet machine? Unlock High-Speed, Precise Tablet Production

- What is the purpose of the pelletizing machine? Transform Waste into Valuable, Dense Pellets