While there is no single type of steel used for all hydraulic presses, critical components are most commonly made from high-strength carbon and alloy steels. For high-stress parts like the main cylinder and piston, grades such as AISI 4140 or 4340 are chosen for their exceptional strength and fatigue resistance. For general structural frames and work platens, a medium-carbon steel like AISI 1045 is often used due to its excellent balance of strength, hardness, and cost-effectiveness.

The specific steel grade is less important than its certified properties. The core principle is selecting a steel with verified high tensile strength, toughness, and internal integrity to safely withstand the immense and repetitive forces generated during operation.

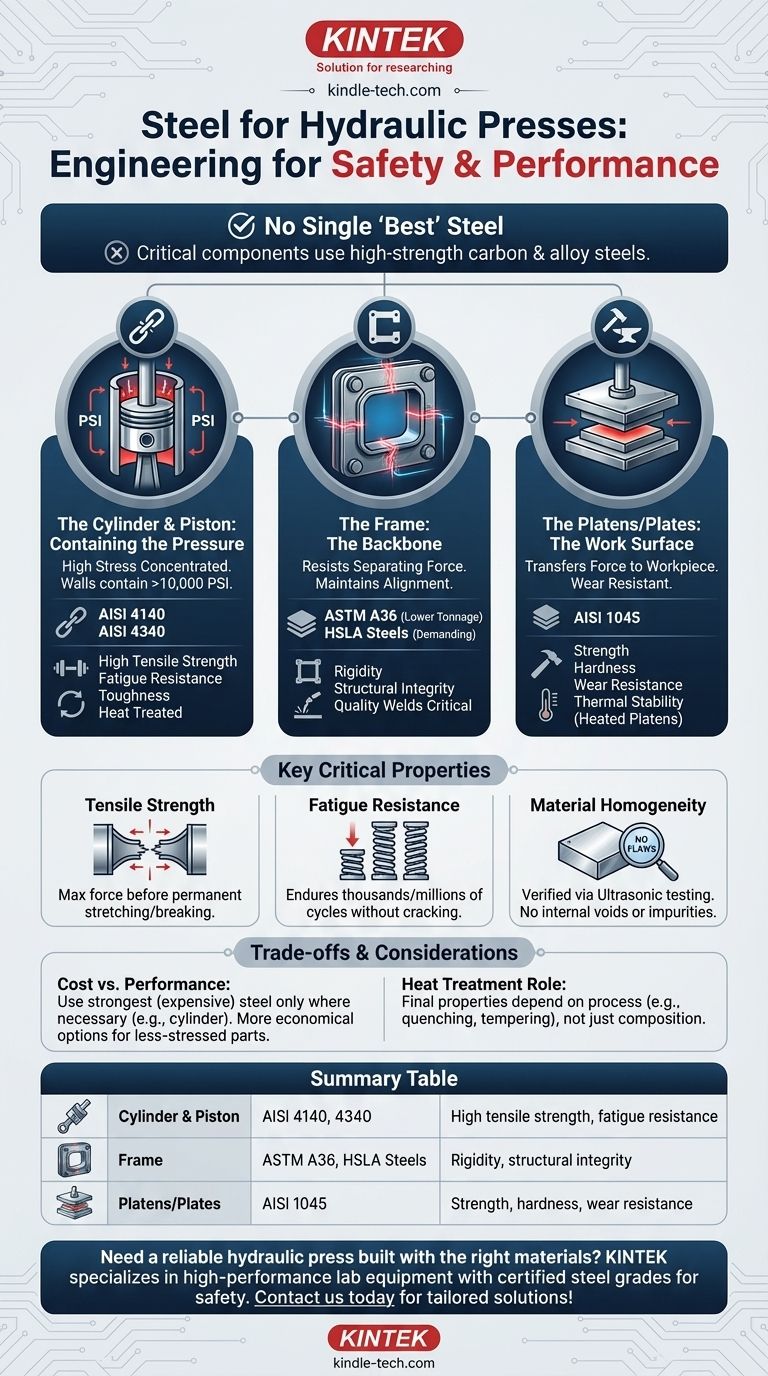

The Anatomy of a Press: Where Steel Matters Most

A hydraulic press is not made from a single block of metal. Different components are subjected to different types of stress, and therefore require different types of steel, each chosen for a specific purpose.

The Frame: The Backbone of the Machine

The frame's primary job is to resist the immense separating force generated between the cylinder and the bed. It must be incredibly rigid to maintain alignment and strong enough to prevent catastrophic failure.

Frames are typically fabricated from heavy steel plates, such as ASTM A36 for lower-tonnage presses or higher-strength low-alloy (HSLA) steels for more demanding applications. The quality of the welds is as critical as the steel itself.

The Cylinder and Piston: Containing the Pressure

This is the heart of the press, where the highest stresses are concentrated. The cylinder walls must contain hydraulic pressures that can exceed 10,000 PSI.

For this reason, cylinders are made from high-strength, seamless steel tubing or forgings. AISI 4140 (a chromium-molybdenum alloy steel) is a very common choice. It offers an excellent combination of high tensile strength, toughness, and fatigue resistance, especially after heat treatment.

The Platens/Plates: The Work Surface

The platens transfer the force to the workpiece. They must be strong, flat, and resistant to wear and deformation.

A medium-carbon steel like AISI 1045 is a frequent choice. It can be hardened to resist surface damage. For heated platen applications, the material's thermal stability and homogeneity are critical to ensure even heating and prevent warping, which is why they undergo strict quality checks.

Key Steel Properties and Why They Are Critical

Understanding the terminology helps clarify why certain steels are chosen over others. The selection is a careful engineering decision based on material science.

Tensile Strength: Resisting Being Pulled Apart

This is the maximum force a material can withstand before it begins to permanently stretch or break. In a press, the cylinder walls are under extreme tension, making this the most critical property for pressure-containing components.

Fatigue Resistance: Enduring Repetitive Cycles

A press doesn't just apply force once; it does so thousands or millions of times. Fatigue is the weakening of a material caused by this repeated loading. Steels like 4140 and 4340 are selected for their ability to endure these cycles without developing cracks.

Material Homogeneity: The Importance of No Flaws

As your reference noted, high-quality steel is verified for ultrasonic homogeneity. This means it is tested to ensure there are no internal voids, impurities, or microscopic cracks. Such flaws can act as stress risers, creating a starting point for catastrophic failure under pressure.

Understanding the Trade-offs

The ideal steel for a hydraulic press is a balance of performance, safety, and cost. There is no perfect, one-size-fits-all solution.

Cost vs. Performance

Alloy steels like 4140 are significantly more expensive than standard carbon steels like 1045 or structural steels like A36. Engineers use the strongest (and most expensive) steel only where it is absolutely necessary, such as for the cylinder, while using more economical options for the frame and other less-stressed components.

The Myth of a Single "Best" Steel

The "best" steel is entirely dependent on the application. A 20-ton shop press has vastly different material requirements than a 2,000-ton forging press. Over-engineering with exotic alloys is wasteful, while under-engineering with low-grade steel is dangerously negligent.

The Critical Role of Heat Treatment

The final properties of a steel are determined as much by its heat treatment as its chemical composition. Processes like quenching and tempering are used to precisely control the final hardness, toughness, and strength of components like the cylinder and platens. The same bar of 4140 steel can have dramatically different characteristics depending on how it is treated.

Making the Right Choice for Your Application

Your focus should be on the intended use and the manufacturer's engineering standards, not just a steel name on a spec sheet.

- If your primary focus is buying a press: Prioritize manufacturers who are transparent about their engineering standards and quality control, including material certifications. A reputable brand's safety factor is more important than a specific alloy name.

- If your primary focus is building a custom press: You must consult a qualified mechanical engineer. Material selection for pressure vessels is a safety-critical discipline that requires professional Finite Element Analysis (FEA) and adherence to established engineering codes.

- If your primary focus is specifying a press for a task: Clearly define your required tonnage, cycle speed, and operating conditions (e.g., heated platens). This information allows an engineer to select the appropriate materials to ensure safety and longevity.

Ultimately, a safe and reliable hydraulic press is the product of sound engineering design, not just the selection of a single material.

Summary Table:

| Component | Common Steel Grades | Key Properties |

|---|---|---|

| Cylinder & Piston | AISI 4140, 4340 | High tensile strength, fatigue resistance |

| Frame | ASTM A36, HSLA Steels | Rigidity, structural integrity |

| Platens/Plates | AISI 1045 | Strength, hardness, wear resistance |

Need a reliable hydraulic press built with the right materials? KINTEK specializes in high-performance lab equipment, including hydraulic presses engineered with certified steel grades for safety and durability. Our experts ensure every component meets rigorous standards for your specific application. Contact us today to discuss your requirements and get a solution tailored to your lab's needs!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

- Assemble Square Lab Press Mold for Laboratory Applications

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- Why KBr is used for IR spectroscopy? The Ideal Medium for Solid Sample Analysis

- What is a cubic press and how does it function? Master High-Volume, Uniform 3D Compression

- What are the specific conditions and steps in HPHT diamond growth? Master the Art of Synthetic Diamond Production

- What is the use of a hydraulic pellet press? Transform Powders into Precise Samples for Analysis

- What role does a Benchtop Hydraulic Press play in sample preparation for solubility tests? Optimize Sample Uniformity.

- What is roll forming used for? Achieve Mass Production of Precise Metal Profiles

- What are the weakness of hydraulic press? Understand the Trade-offs of Power and Control

- Why use a laboratory hydraulic press for metal powders? Achieve High-Density Green Bodies for Hot Pressing