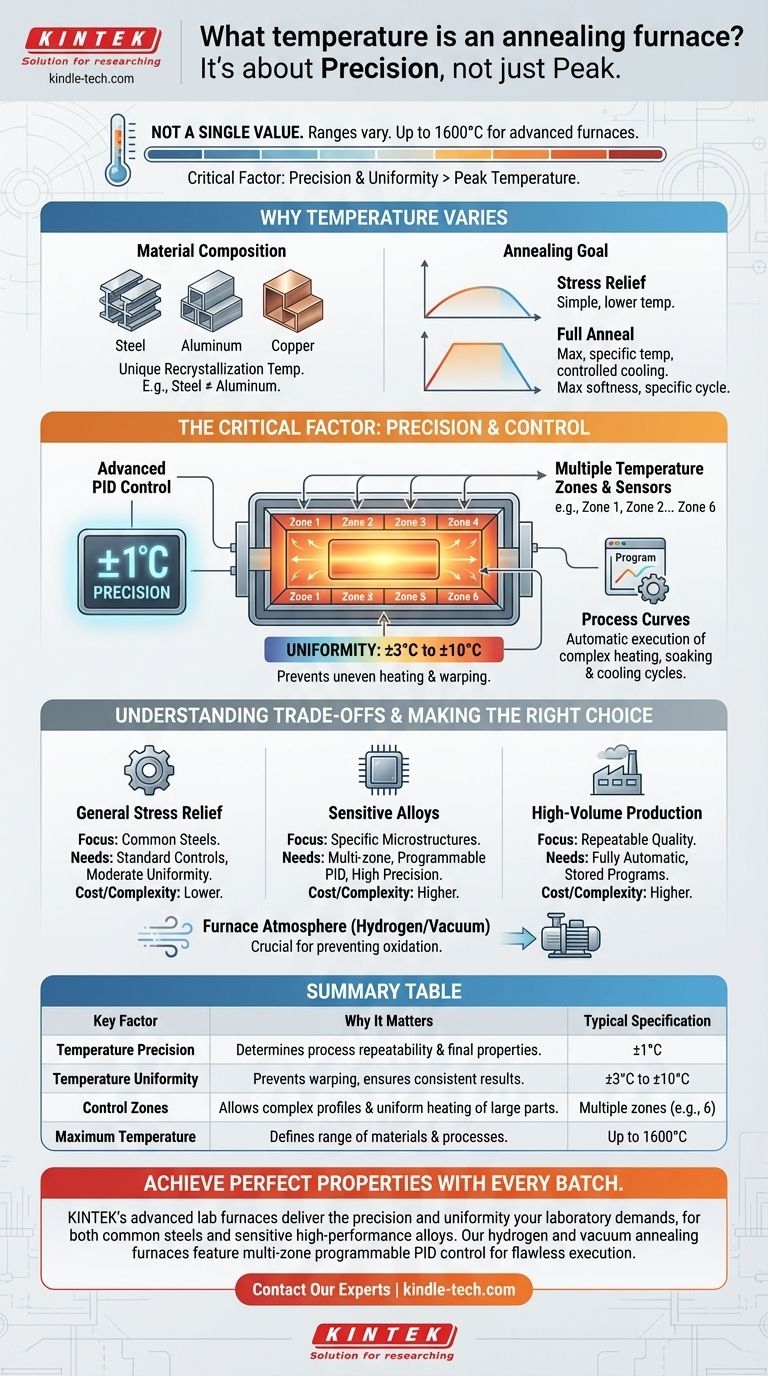

The temperature of an annealing furnace is not a single value. It varies significantly based on the material being treated and the desired outcome, with some advanced hydrogen furnaces capable of reaching a maximum temperature of 1600℃. The critical factor is not the peak temperature itself, but the extreme precision and uniformity with which that temperature is controlled throughout the process.

The specific temperature for annealing is entirely material-dependent. The true measure of an annealing furnace's quality lies in its ability to achieve and maintain that target temperature with exceptional precision (often within ±1°C) and uniformity across the entire workpiece.

Why Temperature Varies in Annealing

The goal of annealing is to alter a material's microstructure to make it softer, more ductile, and less brittle. This is achieved by heating it to a specific temperature, holding it there, and then cooling it at a controlled rate. The "specific temperature" is the key variable.

The Role of Material Composition

Every metal and alloy has a unique recrystallization temperature—the point at which new, strain-free grains form. Annealing is typically performed at or above this temperature. For example, the annealing temperature for steel is vastly different from that for aluminum or copper.

The Goal of the Annealing Process

Different annealing processes require different temperature profiles. A simple stress-relief anneal might only require a relatively low temperature, while a full anneal to achieve maximum softness requires heating to a much higher, more specific point.

The Critical Factor: Precision and Control

Modern annealing furnaces are sophisticated systems designed not just to get hot, but to achieve a specific thermal profile with absolute reliability. This is where the engineering focus lies.

Achieving High Precision

The most advanced furnaces achieve a temperature control precision of ±1℃. This is accomplished using intelligent control systems, often an expert PID (Proportional-Integral-Derivative) self-tuning program controller. This controller continuously adjusts the power supplied to the heating elements, ensuring the temperature remains stable.

Ensuring Temperature Uniformity

It's not enough for one spot in the furnace to be at the correct temperature; the entire workpiece must be. Furnaces are often divided into multiple temperature control zones (e.g., six zones) with separate sensors. This ensures temperature uniformity, typically within ±3℃ to ±10℃, preventing uneven heating that could cause warping or inconsistent material properties.

Programmatic Temperature Control

Annealing follows a specific recipe or "process curve." A piecewise program temperature controller allows operators to store multiple programs. The furnace can then automatically execute complex heating, soaking (holding at temperature), and cooling cycles required for different materials and outcomes.

Understanding the Trade-offs

Choosing or specifying an annealing furnace involves balancing capability with cost and complexity. Not every application requires the highest level of performance.

The Cost of Precision

Achieving ±1°C precision and high uniformity requires sophisticated components like imported PID controllers, multiple temperature zones, and advanced power regulators (thyristors or solid-state modules). These add significant cost and complexity to the furnace design.

Process Complexity vs. Simplicity

For basic stress relief on robust parts, a simpler furnace with fewer control zones and less precise control may be perfectly adequate. For sensitive, high-performance alloys, the multi-zone, programmable control is non-negotiable to achieve the desired metallurgical properties without defects.

Furnace Atmosphere

The references mention both hydrogen and vacuum annealing furnaces. The choice of atmosphere is critical to the process, as it prevents oxidation at high temperatures. While not a direct temperature trade-off, the furnace design must accommodate the requirements of maintaining and controlling this atmosphere alongside the temperature.

Making the Right Choice for Your Goal

The correct annealing temperature is dictated by your material and objective. The quality of your furnace is determined by its ability to meet that temperature profile precisely.

- If your primary focus is general stress relief on common steels: A furnace with standard controls and moderate temperature uniformity is likely sufficient.

- If your primary focus is achieving specific microstructures in sensitive alloys: You must prioritize a furnace with multi-zone, programmable PID control for the highest precision and uniformity.

- If your primary focus is high-volume, repeatable production: A system with stored programs and fully automatic temperature control is essential for ensuring consistent quality from batch to batch.

Ultimately, mastering the annealing process is about mastering precise and repeatable thermal control.

Summary Table:

| Key Factor | Why It Matters | Typical Specification |

|---|---|---|

| Temperature Precision | Determines process repeatability and final material properties. | ±1°C |

| Temperature Uniformity | Prevents warping and ensures consistent results across the workpiece. | ±3°C to ±10°C |

| Control Zones | Allows for complex thermal profiles and uniform heating of large parts. | Multiple zones (e.g., 6) |

| Maximum Temperature | Defines the range of materials and processes possible. | Up to 1600°C |

Achieve perfect material properties with every batch. The right annealing process is defined by precise temperature control. Whether you are stress-relieving common steels or working with sensitive high-performance alloys, KINTEK's advanced lab furnaces deliver the precision and uniformity your laboratory demands.

Our hydrogen and vacuum annealing furnaces feature multi-zone programmable PID control to ensure your specific thermal profile is executed flawlessly. Let's discuss your application and ensure your results are never compromised by inadequate equipment.

Contact our thermal processing experts today to find the ideal annealing solution for your lab.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control