There is no single "best" heat treatment process. The optimal choice is entirely dependent on the final properties you need the material to possess. Each process modifies the metal's internal crystalline structure—its microstructure—to achieve a specific outcome, such as making it softer for machining or harder for wear resistance.

The core principle of heat treatment is not to find the "best" process, but to match the right process to your specific engineering goal. Understanding whether you need hardness, softness, toughness, or structural uniformity is the first and most critical step.

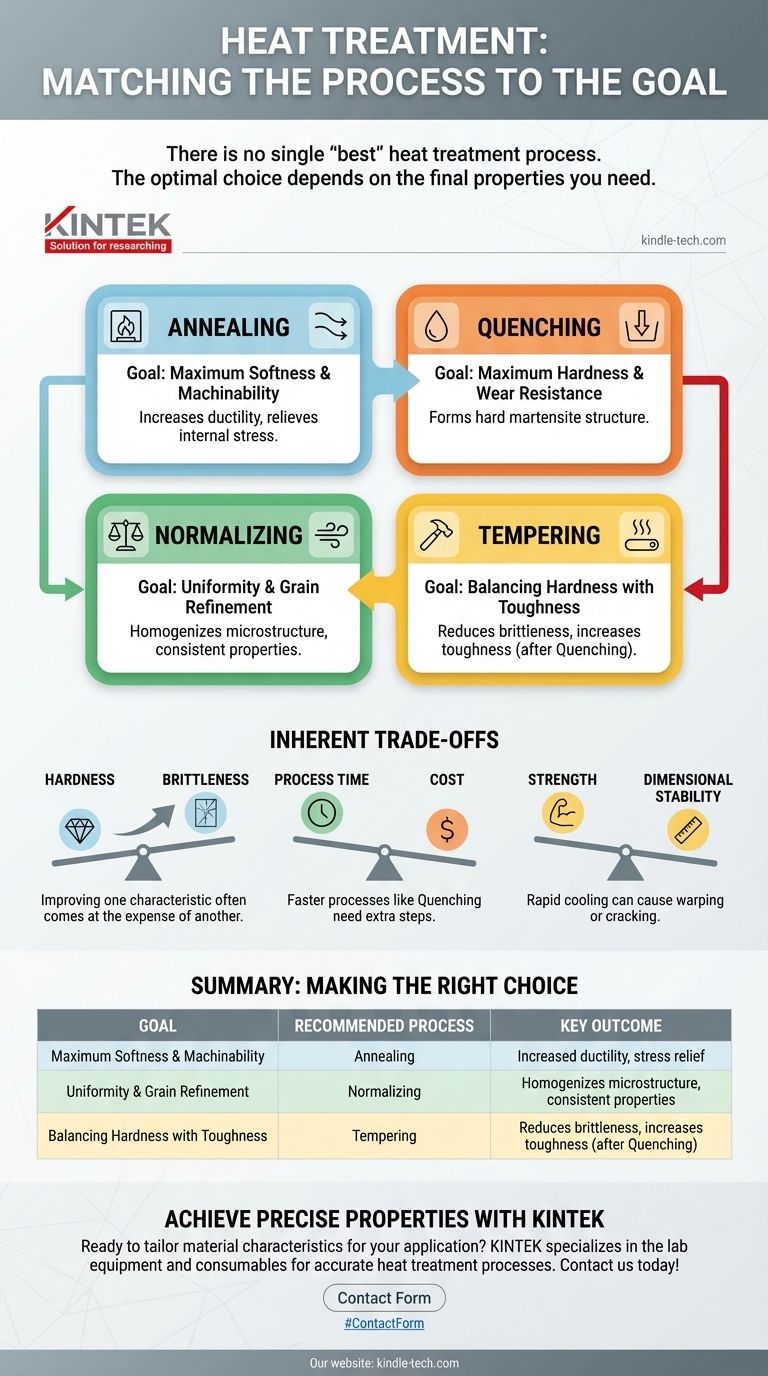

The Goal-Driven Nature of Heat Treatment

Heat treatment is best understood as a toolkit. Each process is a specialized tool designed to produce a distinct set of mechanical properties. The selection process begins by defining the end-use of the component.

Goal: Maximum Softness and Machinability (Annealing)

Annealing is a process that involves heating a metal to a specific temperature and then cooling it very slowly.

This slow cooling allows the material's internal microstructure to reset into its most stable, low-energy state.

The primary result is a significant reduction in hardness and an increase in ductility, making the metal easier to machine, form, or shape without fracturing. It is also highly effective at relieving internal stresses from previous manufacturing steps.

Goal: Maximum Hardness and Wear Resistance (Quenching)

Quenching is the opposite of annealing in its cooling phase. The material is heated to a critical temperature and then cooled with extreme rapidity by submerging it in a medium like water, oil, or brine.

This rapid cooling freezes a very hard, brittle, and unstable crystalline structure called martensite in place.

The goal of quenching is to achieve maximum surface hardness, which is essential for components that must resist wear, abrasion, and indentation.

Goal: Balancing Hardness with Toughness (Tempering)

A quenched part is often too brittle for practical use; it can shatter under impact. Tempering is a secondary process performed after quenching to solve this problem.

The hardened part is reheated to a lower temperature and held for a specific time. This process relieves some internal stresses and allows the brittle martensite structure to transform slightly.

Tempering reduces some of the extreme hardness gained during quenching but, in return, significantly increases the material's toughness—its ability to absorb energy and deform without fracturing.

Goal: Uniformity and Grain Refinement (Normalizing)

Normalizing, like annealing, involves heating the material and then cooling it. However, the cooling is done in open air, which is faster than the slow furnace-cooling of annealing but much slower than quenching.

The primary purpose of normalizing is to create a more uniform and fine-grained microstructure. This process is often used on materials that have been forged or cast to homogenize the structure and ensure consistent, predictable mechanical properties throughout the part.

Understanding the Inherent Trade-offs

Choosing a heat treatment process always involves balancing competing properties. Improving one characteristic often comes at the expense of another.

Hardness vs. Brittleness

This is the most fundamental trade-off. As you increase a material's hardness (its resistance to scratching and indentation), you almost always increase its brittleness (its tendency to fracture without warning).

A fully quenched steel is exceptionally hard but can be as brittle as glass. Tempering is the deliberate act of trading a small amount of that hardness to gain a large amount of essential toughness.

Process Time vs. Cost

The cooling rate directly impacts process time and cost. Full annealing, with its slow furnace-cooling requirements, can take many hours or even days, making it a more expensive operation.

Normalizing is faster because it cools in ambient air. Quenching is the fastest but requires an additional tempering step, adding complexity and time to the overall workflow.

Strength vs. Dimensional Stability

Rapid heating and cooling can introduce significant internal stresses into a component.

Processes like quenching can cause parts to warp, distort, or even crack if not managed carefully. Slower processes like annealing and normalizing are far more dimensionally stable.

Making the Right Choice for Your Goal

Your selection should be guided by the final application of the component.

- If your primary focus is preparing a part for extensive machining: Choose annealing to achieve maximum softness and relieve internal stress.

- If your primary focus is creating a wear-resistant surface for a tool or bearing: Choose quenching, but always follow it with tempering to prevent catastrophic failure.

- If your primary focus is a structural component that must withstand impact (e.g., an axle or bolt): Choose quenching followed by tempering to achieve the optimal balance of hardness and toughness.

- If your primary focus is ensuring consistent mechanical properties after a forging process: Choose normalizing to refine the grain structure and homogenize the material.

Ultimately, selecting the right heat treatment begins not with the process, but with a clear definition of your material's end-use.

Summary Table:

| Goal | Recommended Process | Key Outcome |

|---|---|---|

| Maximum Softness & Machinability | Annealing | Increased ductility, stress relief |

| Maximum Hardness & Wear Resistance | Quenching | Forms hard martensite structure |

| Balance Hardness with Toughness | Tempering (after Quenching) | Reduces brittleness, increases toughness |

| Uniformity & Grain Refinement | Normalizing | Homogenizes microstructure, consistent properties |

Ready to achieve the perfect material properties for your application?

At KINTEK, we specialize in providing the precise lab equipment and consumables needed to execute heat treatment processes like annealing, quenching, tempering, and normalizing with accuracy and repeatability. Whether you're in R&D, quality control, or production, our solutions help you tailor material characteristics—from hardness and wear resistance to toughness and machinability—to meet your specific engineering goals.

Contact us today using the form below to discuss your heat treatment challenges and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing