While rapid prototyping remains the most widespread use of additive manufacturing, its most applied and highest-value area is in the direct production of functional, end-use parts. This shift from models to mission-critical components is most prominent in industries like aerospace and medical, where the unique benefits of 3D printing—namely complex geometries and customization—provide a value that traditional manufacturing cannot easily replicate.

Additive manufacturing has evolved far beyond its origins as a prototyping tool. Its greatest impact today is in creating finished components where design complexity, mass customization, or extreme weight reduction are the primary engineering goals.

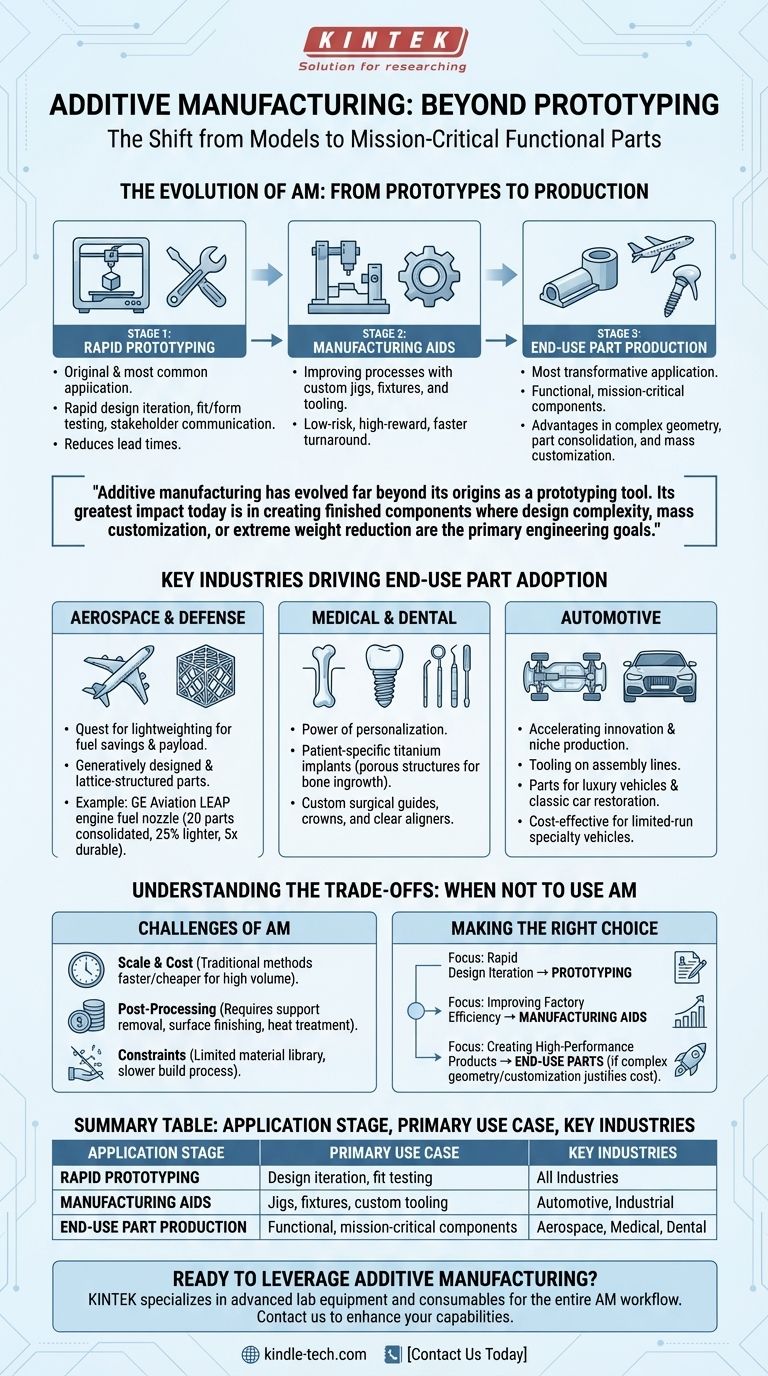

The Evolution of AM: From Prototypes to Production

Additive Manufacturing (AM), or 3D printing, did not become a production technology overnight. Its applications have evolved in distinct stages, each building on the last.

The Foundation: Rapid Prototyping

This is the original and still most common application of AM. For decades, engineers have used 3D printers to quickly create physical models of digital designs.

The value is simple: it allows for rapid design iteration, fit and form testing, and stakeholder communication long before committing to expensive tooling for mass production.

The Bridge: Manufacturing Aids

The next logical step was using AM to improve the manufacturing process itself. This involves printing jigs, fixtures, and other custom tooling.

This application is a low-risk, high-reward entry point for many companies. A custom fixture that might have taken weeks to machine can often be printed overnight, dramatically reducing lead times and costs on the factory floor.

The Pinnacle: End-Use Part Production

This is the most transformative application area. Here, the printed part is not a model or a tool—it is the final product delivered to the customer.

This is only viable when AM provides a distinct advantage over traditional methods. These advantages typically fall into three categories: complex geometry, part consolidation, and mass customization.

Key Industries Driving End-Use Part Adoption

Certain industries were quick to recognize the production potential of AM because their needs align perfectly with its strengths.

Aerospace and Defense: The Quest for Lightweighting

In aviation, every gram of weight saved translates directly into fuel savings or increased payload capacity over the life of an aircraft.

AM allows engineers to create generatively designed and lattice-structured parts that are impossibly complex to machine yet offer incredible strength-to-weight ratios.

A famous example is the GE Aviation LEAP engine fuel nozzle. AM allowed designers to consolidate 20 individual components into a single, complex part that is 25% lighter and five times more durable.

Medical and Dental: The Power of Personalization

No two human bodies are alike, making medicine a perfect fit for AM's customization capabilities.

Orthopedic surgeons use AM to create patient-specific titanium implants, such as hip cups, with porous structures that encourage bone ingrowth. Dentists and orthodontists print millions of custom surgical guides, crowns, and clear aligners.

Automotive: Accelerating Innovation and Niche Production

The automotive industry uses AM extensively for prototyping new vehicle designs. However, it is also a key enabler for tooling on assembly lines and the production of parts for luxury vehicles and classic car restoration.

For high-volume production, AM is still too slow, but for limited-run specialty vehicles, it provides a cost-effective way to create complex parts without expensive tooling.

Understanding the Trade-offs: When Not to Use AM

To apply AM effectively, it is critical to understand its limitations. It is a powerful tool, but it is not the right tool for every job.

The Challenge of Scale and Cost

For producing thousands of identical, simple parts, traditional methods like injection molding or CNC machining are almost always faster and cheaper per part. The primary cost of AM is in machine time and material, not tooling.

The Reality of Post-Processing

Parts rarely come out of a printer ready for use. They often require support structure removal, surface finishing, heat treatment, or other steps to meet final specifications. These post-processing steps add time and cost to the workflow.

The Constraints of Materials and Speed

While the library of AM-compatible materials is growing, it is still a fraction of what is available for traditional manufacturing. Furthermore, building parts layer-by-layer is an inherently slower process per part than stamping or molding.

Making the Right Choice for Your Goal

The "most applied" area of AM is less important than the right application for your specific objective.

- If your primary focus is rapid design iteration: Prototyping is your key application. Use it to fail fast, learn quickly, and perfect your design before committing to production.

- If your primary focus is improving factory efficiency: Look to manufacturing aids. Printing custom jigs and fixtures is a proven, high-ROI strategy to reduce lead times and improve process quality.

- If your primary focus is creating high-performance products: End-use parts are your goal, but only if your design requires complex geometry, lightweighting, or customization that justifies the cost.

Ultimately, the best application of additive manufacturing is the one where its unique capabilities solve a specific engineering or business challenge that other methods cannot.

Summary Table:

| Application Stage | Primary Use Case | Key Industries |

|---|---|---|

| Rapid Prototyping | Design iteration and fit testing | All industries |

| Manufacturing Aids | Jigs, fixtures, and custom tooling | Automotive, Industrial |

| End-Use Part Production | Functional, mission-critical components | Aerospace, Medical, Dental |

Ready to leverage additive manufacturing for your production needs? KINTEK specializes in providing advanced lab equipment and consumables that support the entire AM workflow, from prototyping to final part production. Whether you are in aerospace, medical, or automotive, our solutions can help you achieve complex geometries, part consolidation, and mass customization. Contact us today to discuss how we can enhance your additive manufacturing capabilities!

Visual Guide

Related Products

- Assemble Lab Cylindrical Press Mold

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is the lifespan of a mold? It's Immortal Unless You Control Moisture

- What is the purpose of using a mold for pellet pressing when preparing catalyst test samples? Ensure Data Consistency

- Why are a laboratory hydraulic press and precision molds required for pressing MAX phase green bodies? - Expert Guide

- What role do high-strength graphite molds play during vacuum hot pressing? Enhance Precision in CuAlMn Composites

- What are the functions of a cylindrical pelleting mold and a hydraulic press in LATP ceramics? Create High-Density Pellets