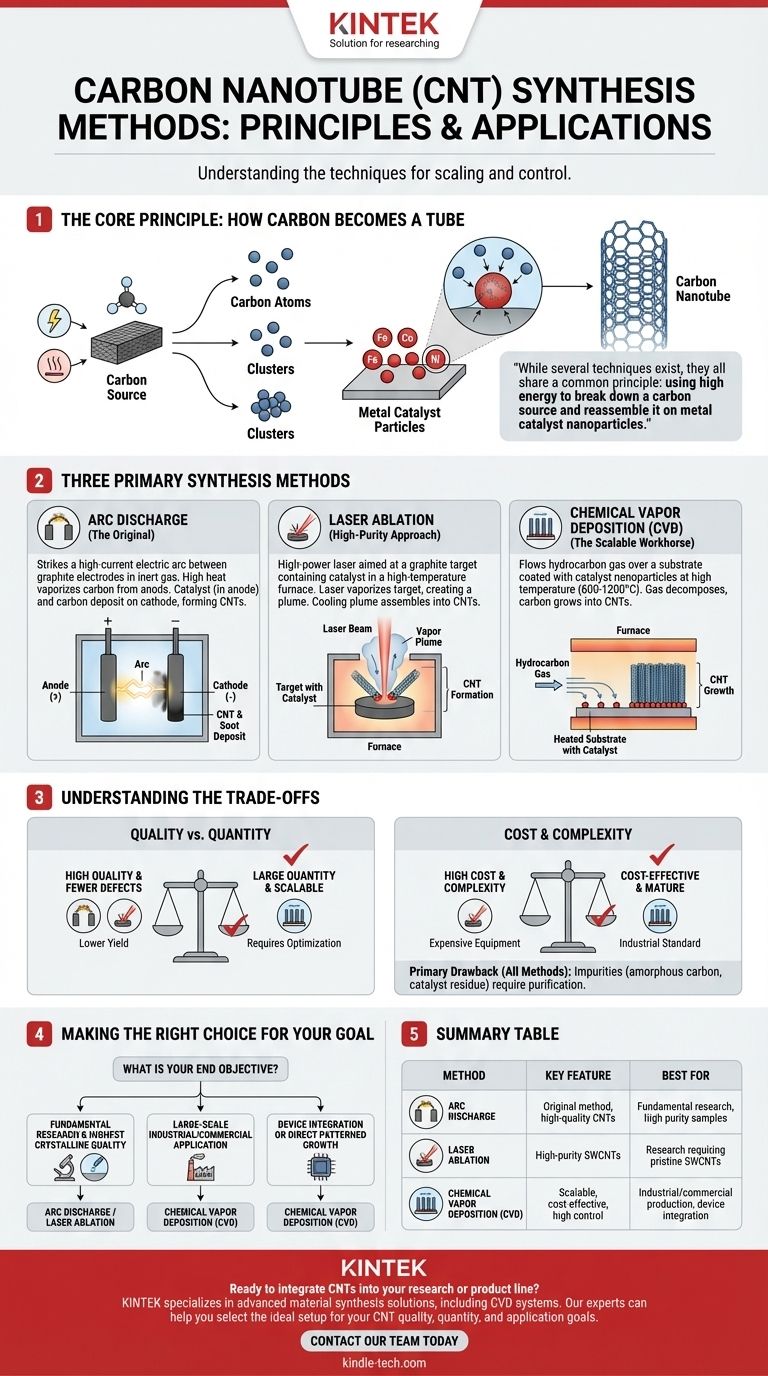

The three primary methods used to synthesize Carbon Nanotubes (CNTs) are arc discharge, laser ablation, and Chemical Vapor Deposition (CVD). While the first two were historically significant, CVD has become the most dominant and commercially viable technique due to its superior scalability and control over the final product.

While several techniques exist, they all share a common principle: using high energy to break down a carbon source and reassemble it on metal catalyst nanoparticles. The choice of method is a critical trade-off between CNT quality, production scale, and cost.

The Core Principle: How Carbon Becomes a Tube

Before comparing specific methods, it's crucial to understand the fundamental mechanism that underpins nearly all CNT synthesis. The process relies on two key steps.

Energizing Carbon Sources

First, a carbon-containing source material must be supplied with enough energy to break it down into highly mobile, individual carbon atoms or small clusters. This source can be solid (like graphite) or gaseous (like methane or acetylene).

The Role of the Metal Catalyst

These carbon atoms then diffuse towards and dissolve into nanosized particles of a metal catalyst, typically iron, cobalt, or nickel. Think of these catalyst particles as seeds. When the catalyst becomes saturated with carbon, the carbon atoms precipitate out, self-assembling into the stable, cylindrical honeycomb lattice of a carbon nanotube.

A Breakdown of the Three Main Synthesis Methods

Each of the three main methods is simply a different way of achieving the two core steps described above.

Arc Discharge: The Original Method

This was the first technique used to produce CNTs. It involves striking a high-current electric arc between two graphite electrodes in an inert gas atmosphere.

The intense heat from the arc vaporizes the carbon from the positive electrode (anode). The catalyst, which is mixed into the anode, and the carbon atoms then deposit on the negative electrode (cathode), forming CNTs among other carbon byproducts like soot.

Laser Ablation: The High-Purity Approach

In this method, a high-power laser beam is aimed at a graphite target that contains a metal catalyst. The process takes place in a high-temperature furnace filled with an inert gas.

The laser's energy vaporizes the target, creating a plume of carbon atoms and catalyst particles. As this plume cools, the carbon atoms assemble into CNTs on the catalyst particles. This method is known for producing high-purity single-walled CNTs (SWCNTs).

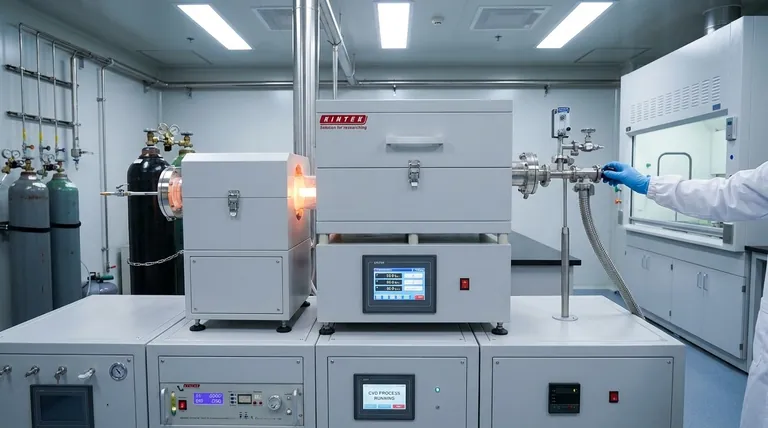

Chemical Vapor Deposition (CVD): The Scalable Workhorse

CVD is the most widely used method in both research and industry. It involves flowing a hydrocarbon gas over a substrate that has been coated with a layer of catalyst nanoparticles.

When heated to high temperatures (typically 600-1200°C), the gas decomposes, releasing carbon atoms that then grow into CNTs on the catalyst sites. CVD offers exceptional control over nanotube length, diameter, and alignment, and it can be scaled up for mass production.

Understanding the Trade-offs

No single synthesis method is perfect for every application. The choice always involves balancing competing priorities.

Quality vs. Quantity

Arc discharge and laser ablation generally produce CNTs with higher structural quality and fewer defects. However, their yield is relatively low.

CVD is unmatched for producing large quantities of CNTs, making it the standard for industrial applications. The quality can be excellent but often requires careful optimization and post-processing.

Cost and Complexity

Laser ablation is the most expensive method due to the cost of the high-power lasers and the low production rate. Arc discharge is less expensive but can be difficult to control.

CVD represents the most cost-effective and technologically mature platform for large-scale production, forming the backbone of the commercial CNT market.

Control and Purity

CVD offers the highest degree of control. By patterning the catalyst on a substrate, it's possible to grow CNTs in specific locations, creating vertically aligned "forests" for applications in electronics and sensors.

The primary drawback of all methods is the presence of impurities, such as amorphous carbon and residual metal catalyst particles, which must be removed through purification steps.

Making the Right Choice for Your Goal

Selecting a synthesis method depends entirely on your end objective.

- If your primary focus is fundamental research and the highest crystalline quality: Arc discharge or laser ablation are the classic choices for producing pristine samples for scientific study.

- If your primary focus is large-scale industrial or commercial application: Chemical Vapor Deposition (CVD) is the only viable method due to its scalability, control, and cost-effectiveness.

- If your primary focus is integrating CNTs directly onto a device or substrate: CVD is the superior method as it allows for direct, patterned growth on a pre-selected surface.

Ultimately, understanding these core methods and their associated trade-offs empowers you to select the appropriate synthesis route for any given nanotechnology application.

Summary Table:

| Method | Key Feature | Best For |

|---|---|---|

| Arc Discharge | Original method, high-quality CNTs | Fundamental research, high purity samples |

| Laser Ablation | High-purity single-walled CNTs (SWCNTs) | Research requiring pristine SWCNTs |

| Chemical Vapor Deposition (CVD) | Scalable, cost-effective, high control | Industrial/commercial production, device integration |

Ready to integrate CNTs into your research or product line? The right synthesis method is critical for success. KINTEK specializes in laboratory equipment and consumables, including solutions for advanced material synthesis like CVD systems. Our experts can help you select the ideal setup to achieve your specific goals for CNT quality, quantity, and application. Contact our team today to discuss how we can support your nanotechnology projects!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs