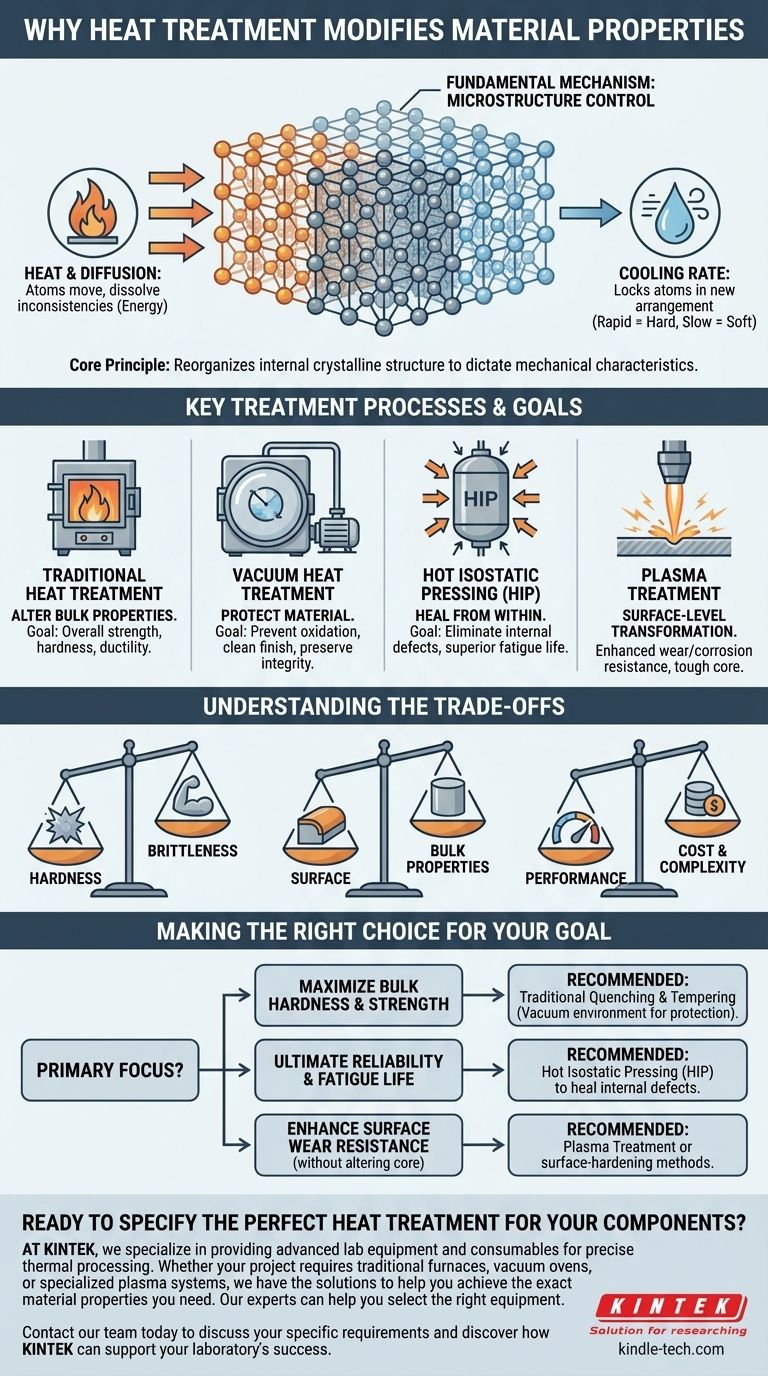

At its core, heat treatment modifies a material's properties by fundamentally reorganizing its internal crystalline structure. By carefully controlling heating and cooling cycles, we manipulate how atoms arrange themselves at a microscopic level. This change in the material's microstructure directly dictates its final mechanical characteristics, such as hardness, strength, and toughness.

The central principle is that heat provides the energy for atoms to move (diffusion), and the rate of cooling locks them into a new, more desirable arrangement. Different treatments are simply different ways of controlling this atomic reorganization to achieve a specific engineering goal.

The Fundamental Mechanism: Microstructure Control

All metals are crystalline, meaning their atoms are arranged in a repeating, orderly lattice. Heat treatment is the process of intentionally altering this lattice to enhance specific properties.

The Role of Heat and Diffusion

Heating a metal injects thermal energy into its atomic structure. This energy allows atoms to break their bonds and move around, or diffuse, within the material. This creates a more uniform and malleable state, dissolving inconsistencies in the microstructure.

The Impact of Cooling

The cooling phase is where the transformation is locked in. The rate of cooling is the most critical variable. A rapid cool (quenching) traps atoms in a highly stressed, disorganized structure, which typically results in high hardness. A slow cool allows atoms to settle into a more orderly, less stressed structure, resulting in a softer, more ductile material.

Key Treatment Processes and Their Goals

While the principle is the same, different methods are used to target specific outcomes, from changes deep within the material to modifications only on its surface.

Traditional Heat Treatment: The Foundation

This involves heating a material to a specific temperature, holding it there to ensure a uniform state, and then cooling it at a controlled rate. The goal is to alter the bulk properties of the entire component, changing its overall strength, hardness, or ductility.

Vacuum Heat Treatment: Protecting the Material

Performing heat treatment in a vacuum is not about changing the mechanism, but about controlling the environment. It prevents oxidation and other surface reactions that can occur at high temperatures. This results in a clean, bright finish and prevents the formation of a weak surface layer, preserving the material's integrity.

Hot Isostatic Pressing (HIP): Healing from Within

HIP combines high heat with immense, uniform pressure. This process physically squeezes the material on all sides, eliminating internal microporosity and microscopic voids. The result is a fully dense material with superior fatigue life, impact strength, and overall consistency.

Plasma Treatment: A Surface-Level Transformation

Unlike methods that alter the entire part, plasma treatment modifies only the surface properties. It uses energized gas (plasma) to promote surface reactions, enhancing characteristics like wear resistance or corrosion resistance without changing the core properties of the material. This leaves the bulk of the component tough and ductile while creating a hard outer "shell."

Understanding the Trade-offs

Choosing a heat treatment process involves balancing desired properties, as enhancing one often comes at the expense of another.

Hardness vs. Brittleness

The most common trade-off is between hardness and toughness. A very hard material, created by rapid quenching, is often also very brittle and prone to fracture. Subsequent tempering (a form of reheating) is often required to restore some toughness, albeit at the cost of some hardness.

Surface vs. Bulk Properties

Processes like plasma treatment create a significant difference between the surface and the core. While this is often desirable for parts needing a wear-resistant surface and a tough interior, it's unsuitable for applications where strength is required throughout the entire component.

Performance vs. Cost and Complexity

Advanced processes deliver superior results but come with higher costs and complexity. Vacuum treatments and HIP, for example, require specialized equipment and are significantly more expensive than traditional atmospheric furnace treatments. The performance gain must justify the investment.

Making the Right Choice for Your Goal

The optimal heat treatment is dictated entirely by the intended application of the component.

- If your primary focus is maximizing bulk hardness and strength: Traditional quenching and tempering, often in a vacuum environment to protect the surface, is the most direct approach.

- If your primary focus is ultimate reliability and fatigue life: Hot Isostatic Pressing (HIP) is the superior choice for healing internal defects in critical components.

- If your primary focus is enhancing surface wear resistance without altering the core: Plasma treatment or other surface-hardening methods provide a targeted solution that preserves the material's underlying toughness.

Ultimately, understanding these processes empowers you to specify a material treatment that precisely matches the engineering demands of your project.

Summary Table:

| Process | Primary Goal | Key Outcome |

|---|---|---|

| Traditional | Alter Bulk Properties | Overall strength, hardness, or ductility |

| Vacuum | Prevent Surface Oxidation | Clean finish, preserved material integrity |

| Hot Isostatic Pressing (HIP) | Eliminate Internal Defects | Superior fatigue life and impact strength |

| Plasma Treatment | Modify Surface Properties | Enhanced wear/corrosion resistance, tough core |

Ready to specify the perfect heat treatment for your components?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise thermal processing. Whether your project requires traditional furnaces, vacuum ovens, or specialized plasma systems, we have the solutions to help you achieve the exact material properties you need.

Our experts can help you select the right equipment to control microstructure, enhance performance, and ensure reliability for your most critical applications.

Contact our team today to discuss your specific requirements and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the function of a high-temperature Box Furnace in rare earth oxide conversion? Enhance Chemical Reactivity

- What is the significance of integrating a high-temperature muffle furnace into an impact wear testing system?

- Which thing is determined in ash content? Measure Inorganic Material for Quality Control

- What is the difference between a box furnace and a muffle furnace? Choose the Right Lab Furnace for Your Application

- How do you use a muffle oven? A Step-by-Step Guide to Safe, Precise Operation

- Why is a Muffle furnace required for the preparation of titanium components? Optimize Passivation and Resistance

- Why is a digital muffle furnace utilized for 270°C treatment? Master CeO2 Nanoparticle Synthesis

- Why is a high-temperature laboratory oven used for Ti-6Al-4V heat treatment? Enhance Durability & Biocompatibility