The fundamental importance of hardening steel is to dramatically increase its hardness and strength through a controlled heat treatment process. This transformation allows a relatively common metal to perform in highly demanding applications where it would otherwise fail.

The core reason for hardening steel is not simply to make it "hard," but to precisely engineer its mechanical properties. It's a critical process for creating components that can withstand intense stress, resist wear, and maintain their structural integrity under extreme conditions.

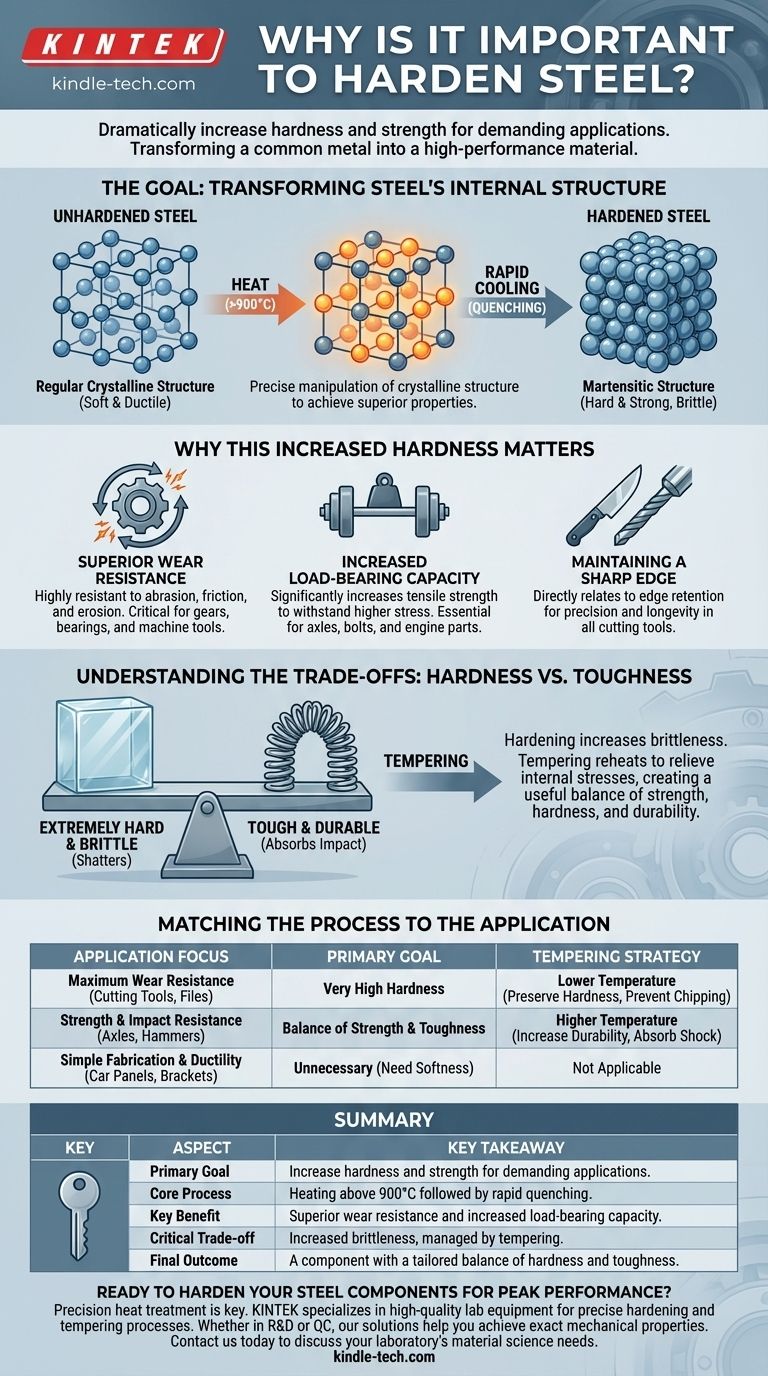

The Goal: Transforming Steel's Internal Structure

Hardening is a deliberate manipulation of steel's crystalline structure to achieve superior performance characteristics.

The Basic Mechanism

The process involves heating steel to a very high temperature, typically above 900°C. This alters its internal atomic arrangement.

It is then rapidly cooled, or quenched, in a medium like oil, water, or gas. This rapid cooling freezes a very hard, strong, but brittle crystalline structure in place.

The Resulting Properties

This transformation yields a material that is significantly harder and stronger than its original, untreated state. This new structure can better resist deformation and surface abrasion.

Why This Increased Hardness Matters

The enhanced properties gained from hardening are essential for countless industrial and commercial applications.

Superior Wear Resistance

A hardened surface is highly resistant to abrasion, friction, and erosion. This is critical for components that are in constant contact with other parts, such as gears, bearings, and machine tools.

Increased Load-Bearing Capacity

Hardening significantly increases steel's tensile strength, which is its ability to withstand pulling forces without breaking. This allows components like axles, structural bolts, and engine parts to handle much higher stress.

Maintaining a Sharp Edge

For any cutting tool, from a simple knife to an industrial drill bit, hardness is directly related to edge retention. A hardened edge will stay sharp far longer than an unhardened one, ensuring precision and longevity.

Understanding the Trade-offs: The Problem of Brittleness

Hardening is a powerful process, but it comes with a critical trade-off that must be managed.

Hardness vs. Toughness

The same process that makes steel extremely hard also makes it very brittle. A fully hardened piece of steel can be as fragile as glass, shattering under a sharp impact rather than bending.

The Role of Tempering

To solve this problem, hardened steel almost always undergoes a second heat treatment called tempering. This involves reheating the part to a lower temperature to relieve internal stresses.

Tempering reduces some of the peak hardness but, crucially, it dramatically increases the steel's toughness—its ability to absorb impact without fracturing. This creates a final product with a useful balance of strength, hardness, and durability.

Matching the Process to the Application

The decision to harden steel and how to temper it depends entirely on the component's final purpose.

- If your primary focus is maximum wear resistance and edge retention (e.g., cutting tools, files): The goal is very high hardness, so tempering will be done at a lower temperature to preserve as much hardness as possible while removing just enough brittleness to prevent chipping.

- If your primary focus is strength and impact resistance (e.g., axles, hammers, structural components): The goal is a balance of strength and toughness, requiring a higher tempering temperature to make the part durable enough to withstand shock loads.

- If your primary focus is simple fabrication and ductility (e.g., car body panels, basic brackets): Hardening is unnecessary and detrimental, as the material needs to be soft enough to be easily formed and is not subjected to high stress or wear.

Ultimately, hardening empowers engineers to turn a standard material into a high-performance component tailored for a specific, demanding job.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Goal | Increase hardness and strength for demanding applications. |

| Core Process | Heating above 900°C followed by rapid quenching. |

| Key Benefit | Superior wear resistance and increased load-bearing capacity. |

| Critical Trade-off | Increased brittleness, which is managed by tempering. |

| Final Outcome | A component with a tailored balance of hardness and toughness. |

Ready to Harden Your Steel Components for Peak Performance?

Precision heat treatment is key to unlocking the full potential of your steel parts. KINTEK specializes in providing the high-quality lab equipment and consumables necessary for precise hardening and tempering processes. Whether you're in R&D or quality control, our solutions help you achieve the exact mechanical properties your application demands.

Contact us today to discuss how KINTEK can support your laboratory's material science and heat treatment needs.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the disadvantages of hardening process? Understanding the Trade-offs of Increased Strength

- Does annealing require furnace cooling? The Key to Achieving Maximum Softness and Stress Relief

- What equipment is used in annealing? Selecting the Right Furnace for Your Process

- What role does a vacuum drying oven play in the calcium thermal reduction process? Preserve High-Purity Metal Powders

- What environmental protection do mechanical vacuum pump sets provide during zirconium alloy melting? Prevent Embrittlement

- How does temperature monitoring affect nickel alloys in SPS? Ensure Precision for High-Performance Sintering

- What function does a laboratory vacuum furnace serve during the 150°C post-treatment of fluorinated carbon aerogels?

- What is the pyrolysis of oil sludge? Turn Hazardous Waste into Valuable Resources