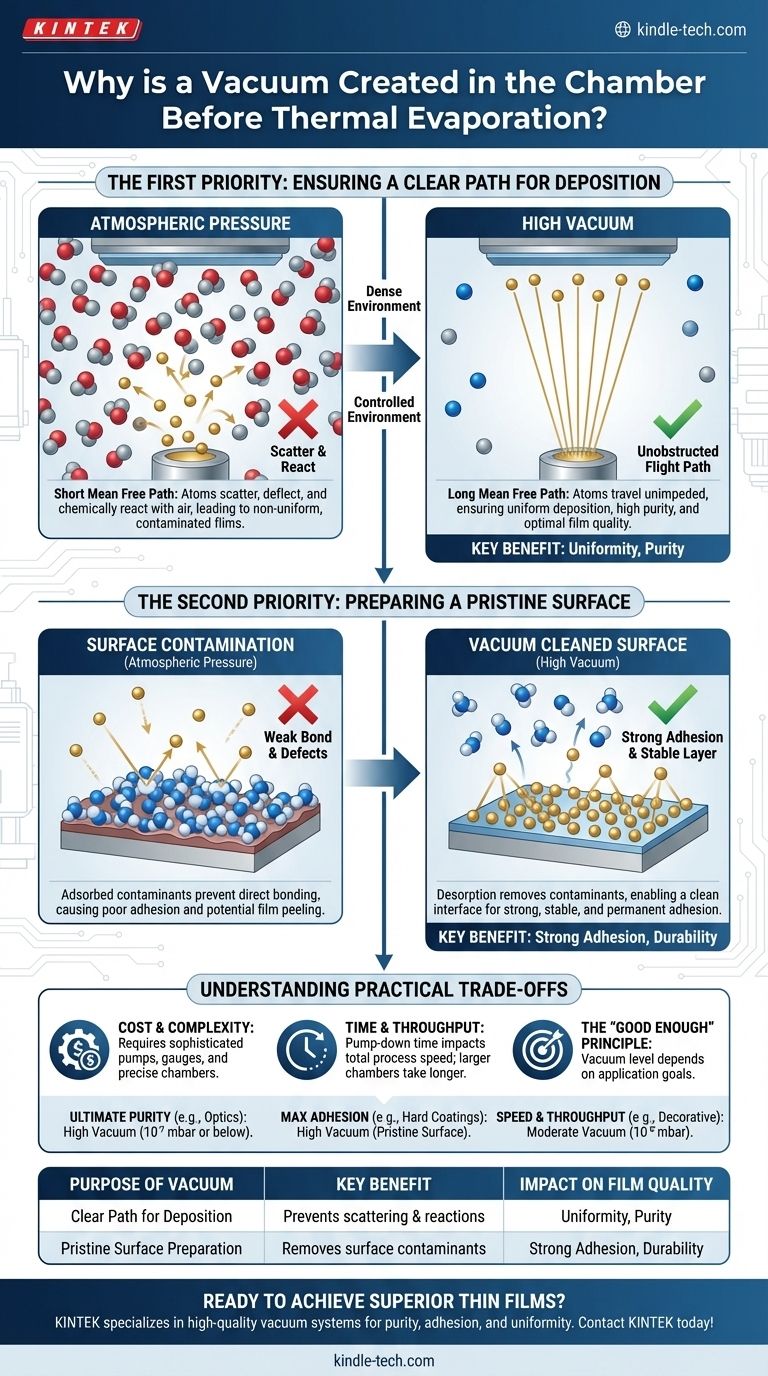

A high vacuum is created in a thermal evaporation chamber for two fundamental reasons: to ensure the evaporated material has a clear, unobstructed flight path to the target, and to prepare a perfectly clean surface for the material to land on. Without a vacuum, the evaporated atoms would collide with air molecules, scattering them and preventing a uniform coating, while a contaminated surface would cause the new film to peel off or have significant defects.

The core purpose of the vacuum is not merely to remove air, but to establish a highly controlled environment. It transforms the chaotic, contaminant-filled space of a chamber at atmospheric pressure into a pristine environment where individual atoms can travel predictably and bond perfectly, ensuring the final film's quality, purity, and adhesion.

The First Priority: Ensuring a Clear Path for Deposition

To understand why the path must be clear, we need to think about the journey of a single evaporated atom. At atmospheric pressure, this journey would be impossible.

The Concept of Mean Free Path

Mean free path is the average distance an atom or molecule can travel before it collides with another one.

In the dense environment of normal air pressure, this distance is incredibly short—on the nanometer scale. The evaporated atom wouldn't even begin its journey before being knocked off course.

By removing almost all the gas molecules, a high vacuum dramatically increases the mean free path, making it much longer than the distance between the material source and the target substrate.

Preventing Unwanted Collisions and Reactions

An unimpeded path is critical for a high-quality film. Collisions with residual gas molecules (like nitrogen or oxygen) have two negative effects.

First, the collision scatters the evaporated atom, deflecting it from its straight-line path. This results in a film that is non-uniform and has lower density.

Second, the hot, reactive evaporated material can chemically react with residual gases mid-flight. For example, a pure metal could form an unwanted oxide, contaminating the final film and changing its properties. A high vacuum minimizes these contaminants to an acceptable level.

The Second Priority: Preparing a Pristine Surface

Even if the atoms arrive perfectly, their landing matters just as much. A surface that seems clean to the naked eye is, at a molecular level, a chaotic landscape of adsorbed contaminants.

The Problem of Surface Contamination

At atmospheric pressure, every surface is covered with a thin layer of molecules from the air, primarily water vapor, nitrogen, and oxygen.

This layer of contamination acts as a barrier, preventing the arriving atoms of evaporated material from forming a strong, direct bond with the substrate itself.

How Vacuum Cleans the Substrate

Creating a vacuum helps these unwanted molecules desorb, or release, from the surface, effectively cleaning it on a molecular level.

This process ensures that when the evaporated atoms arrive, they land on a truly clean substrate, ready to form a direct, powerful bond.

The Impact on Adhesion and Film Quality

The ultimate goal is a film that sticks permanently and performs its function.

A clean, vacuum-prepared surface allows for strong adhesion and the formation of a stable, well-structured layer. Without it, the deposited film would likely have poor adhesion, leading to it flaking or peeling off easily.

Understanding the Practical Trade-offs

While essential, achieving and maintaining a high vacuum involves important considerations that influence the cost, time, and complexity of the process.

Cost and Complexity

High-vacuum systems require sophisticated and expensive equipment, including multiple types of pumps (like roughing pumps and turbomolecular pumps), gauges, and a precisely engineered chamber. Operating and maintaining this equipment demands specialized knowledge.

Time and Throughput

Pumping a chamber down from atmospheric pressure to a high vacuum (e.g., 10⁻⁶ mbar) is not instantaneous. This "pump-down time" can be a significant portion of the total process time, directly impacting manufacturing throughput. Larger chambers or materials that release gases (outgassing) will increase this time.

The "Good Enough" Principle

The required level of vacuum depends entirely on the application. The typical range of 10⁻⁵ to 10⁻⁷ mbar reflects this. A decorative metallic coating on plastic may only require a moderate vacuum, while an optical coating for a precision lens will demand a much higher vacuum to ensure purity and performance.

Making the Right Choice for Your Goal

The level of vacuum you target should be directly tied to the desired characteristics of your final film.

- If your primary focus is ultimate purity and performance (e.g., optics, semiconductors): Your priority is a higher vacuum (lower pressure, 10⁻⁷ mbar or below) to minimize contaminants and ensure a collisionless path.

- If your primary focus is maximum adhesion and durability (e.g., hard coatings): Your priority is ensuring a pristine substrate, which means a high vacuum is non-negotiable to remove surface contaminants.

- If your primary focus is speed and high throughput (e.g., decorative coatings): A moderate vacuum (around 10⁻⁵ mbar) may be sufficient, providing a balance between acceptable film quality and faster processing times.

Ultimately, controlling the vacuum is the primary method for controlling the fundamental quality and integrity of your deposited film.

Summary Table:

| Purpose of Vacuum | Key Benefit | Impact on Film Quality |

|---|---|---|

| Clear Path for Deposition | Prevents scattering & reactions | Uniformity, Purity |

| Pristine Surface Preparation | Removes surface contaminants | Strong Adhesion, Durability |

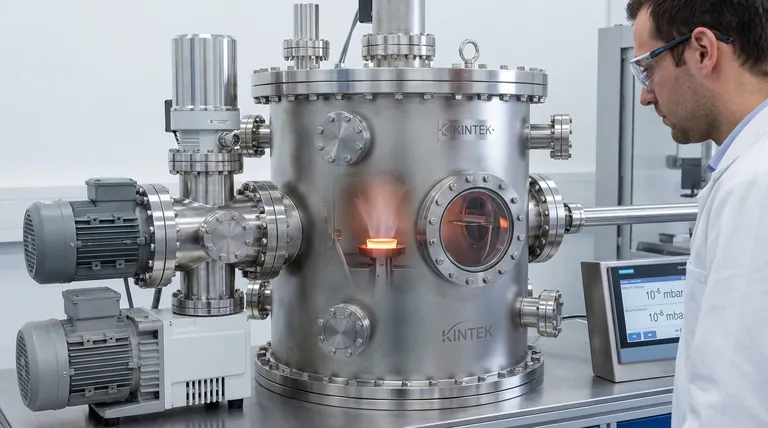

Ready to achieve superior thin films with your thermal evaporation process? The right vacuum environment is critical for success. At KINTEK, we specialize in high-quality lab equipment, including vacuum systems and thermal evaporation components, to help you achieve the purity, adhesion, and uniformity your applications demand. Let our experts guide you to the optimal solution for your laboratory's specific needs. Contact KINTEK today to discuss your project!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- What temperature do you heat treat a furnace? It's All About Your Material and Goal

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- What are the most commonly used metals in a vacuum furnace's hot zone? Discover the Key to High-Purity Processing