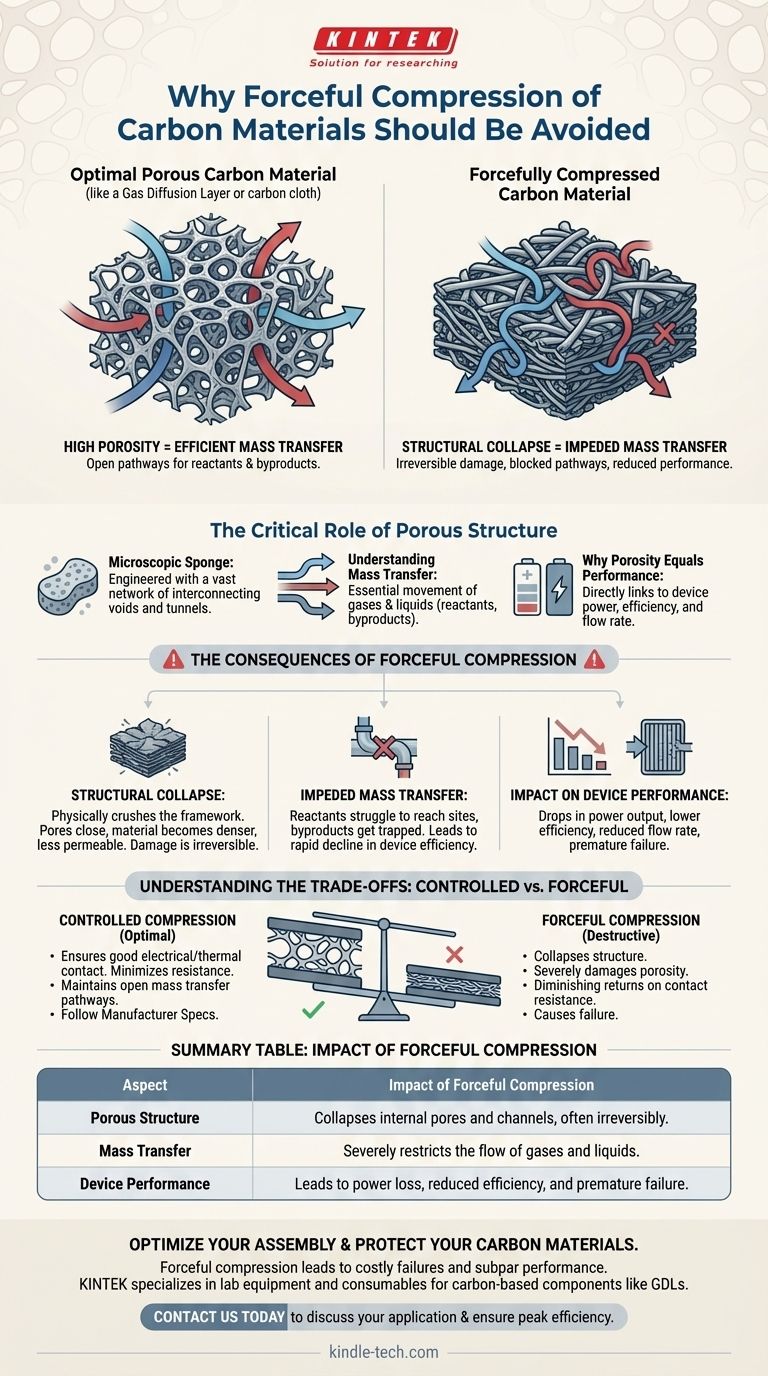

At its core, forceful compression of carbon materials should be avoided because it physically damages their internal porous structure. This collapse of the material's microscopic architecture directly compromises its ability to transport gases and liquids, which is the very function that makes it valuable in most high-performance applications.

The primary value of porous carbon materials lies in their intricate internal network of pores and channels. Forcefully compressing them is like crushing a sponge into a hard, flat sheet—it permanently destroys the pathways essential for performance, a concept known as mass transfer.

The Critical Role of Porous Structure

To understand the damage, you must first appreciate why the structure exists. Many advanced carbon materials, like carbon cloth, felt, or paper, are not solid blocks but are engineered to be highly porous.

A Microscopic Sponge

Think of these materials as a rigid, microscopic sponge. They are composed of a solid carbon framework interwoven with a vast network of interconnected voids and tunnels.

This internal architecture is not an accident; it is the material's key feature. It creates an incredibly high surface area and a permeable medium, allowing fluids and gases to move through it efficiently.

Understanding Mass Transfer

Mass transfer is the movement of chemical species from one point to another. In the context of carbon materials used in devices like fuel cells or batteries, this means delivering reactants (like hydrogen and oxygen) to the active sites and removing byproducts (like water).

The porous network acts as a superhighway system for this transfer. Wide, interconnected pores ensure reactants arrive quickly and waste products are cleared without causing "traffic jams."

Why Porosity Equals Performance

The efficiency of mass transfer is directly linked to device performance.

Fast, unrestricted mass transfer means a fuel cell can generate more power, a battery can charge and discharge faster, and a filter can process more fluid with less energy. The porous structure is the foundation of this high performance.

The Consequences of Forceful Compression

When you apply excessive force, you are working directly against the material's engineered design.

Structural Collapse Explained

Forceful compression physically crushes the carbon framework. The delicate pores and channels collapse, closing off the carefully designed pathways.

This damage is often irreversible. The material becomes denser, less permeable, and loses the very properties it was chosen for. The microscopic sponge is flattened, and its ability to absorb and transport is lost.

Impeded Mass Transfer

With the internal "highways" blocked or destroyed, mass transfer is severely restricted.

Reactants struggle to reach the reaction sites, effectively starving the device of its fuel. Byproducts get trapped, flooding the system and preventing further reactions from occurring. This leads to a rapid decline in operational efficiency.

The Impact on Device Performance

This internal failure manifests as poor external performance.

In a fuel cell, it results in a significant drop in power output and efficiency. In a flow battery, it can limit the achievable current density. In a water filter, it would lead to a dramatically reduced flow rate and a higher likelihood of clogging.

Understanding the Trade-offs: Controlled vs. Forceful Compression

While forceful compression is destructive, a certain degree of controlled compression is often necessary, particularly in electrochemical devices.

The Need for Good Contact

In systems like fuel cell or electrolyzer stacks, components are pressed together. This controlled compression serves a critical purpose: ensuring good electrical and thermal contact between layers.

Without sufficient contact, electrical resistance increases, generating waste heat and lowering overall system efficiency.

Finding the Optimal "Squeeze"

The key is to apply just enough pressure to establish good contact without collapsing the porous structure. This is a crucial engineering balance.

There is an optimal compression range where electrical resistance is minimized, and the mass transfer pathways remain open. Going beyond this point yields diminishing returns on contact resistance while severely damaging the material's porosity.

The Role of Manufacturer Specifications

Because of this delicate balance, manufacturers of components like Gas Diffusion Layers (GDLs) provide specific data on recommended compression ratios (e.g., 15-25%). Deviating from these specifications by applying excessive force is a direct cause of premature component failure and poor device performance.

Applying This to Your Project

Your approach should be guided by the specific demands of your application.

- If your primary focus is electrochemical performance (fuel cells, batteries): You must precisely control compression to the manufacturer's specification to balance low electrical resistance with high mass transfer capability.

- If your primary focus is filtration or separation: Avoid significant compression entirely, as any reduction in pore volume will directly impede flow rate and increase the energy needed for operation.

- If you are assembling a multi-layer device: Treat compression as a critical engineering parameter, not an afterthought. Use torque wrenches and pressure-sensitive films to verify you are in the optimal range.

Ultimately, respecting the material's internal architecture is fundamental to unlocking its performance.

Summary Table:

| Aspect | Impact of Forceful Compression |

|---|---|

| Porous Structure | Collapses internal pores and channels, often irreversibly. |

| Mass Transfer | Severely restricts the flow of gases and liquids. |

| Device Performance | Leads to power loss in fuel cells, reduced efficiency in batteries. |

| Key Takeaway | Controlled compression is necessary; forceful compression is destructive. |

Optimize your assembly process and protect your carbon materials.

Forceful compression can lead to costly failures and subpar performance in your lab equipment. KINTEK specializes in lab equipment and consumables, providing the expertise and products to ensure your carbon-based components, like Gas Diffusion Layers (GDLs), are handled correctly. We help you achieve the perfect balance of electrical contact and preserved porosity for peak efficiency.

Contact us today (#ContactForm) to discuss your specific application and ensure your materials perform as engineered.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What are the two classifications of press machines? Single Punch vs. Rotary Presses Explained

- What is the advantage of a single punch tablet machine? Ideal for Low-Waste R&D and Formulation Testing

- What is the pressed pellet technique? A Guide to Creating Uniform Solid Samples from Powder

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production