High Pressure Reactor

Mini SS High Pressure Autoclave Reactor for Laboratory Use

Item Number : KV-3H

Price varies based on specs and customizations

- Reactor material

- 304/316L Stainless Steel

- Work temperature

- 260 ℃

- Max.work pressure

- 22 Mpa

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Reliable PartnerEasy ordering process, quality products, and dedicated support for your business success.

Applications

Mini stainless steel reactor is widely used in medicine, beverage, chemical industry, paint, resin, scientific research and industry departments,etc, its heating temperature and speed can programmed according to different reaction processing requirement, reactor material can be 304 or 316L, which can work for different temperatures, max. Working pressure is up to 22Mpa. Its stirring method can be magnetic stirring or mechanical agitating, stirring speed is adjustable. Pressure gauge and vent port valve can be designed in different packages,which will meet different application purposes.

Detail & Parts

KT-HPR-C Series Technical Parameters

1. Motor 2. Circulation port 3. Venting/Feeding valve 4. Discharge valve 5. LCD display

6. Operating buttons 7. Pressure gauge 8. Explosion-proof valve 9. Operating handle

| Model | KT-HPR-C50 | KT-HPR-C100 | KT-HPR-C250 | KT-HPR-C500 |

|---|---|---|---|---|

| Volume | 50mL | 100mL | 250mL | 500mL |

| Material | 304/316 Stainless Steel | 304/316 Stainless Steel | 304/316 Stainless Steel | 304/316 Stainless Steel |

| Design Temp | 270°C | 350°C | 350°C | 350°C |

| Heating/Cooling Rate | ≤3°C/min | ≤3°C/min | ≤3°C/min | ≤3°C/min |

| Design Pressure | 22Mpa | 22Mpa | 22Mpa | 22Mpa |

| Stirring Speed | 0-1000r/min | 0-1000r/min | 0-1000r/min | 0-1000r/min |

| Heating Power | 0.7Kw | 0.7Kw | 0.7Kw | 0.7Kw |

| Heating Method | Modular Electric Heating | Modular Electric Heating | Modular Electric Heating | Modular Electric Heating |

| Stirring Method | Mechanical Stirring | Mechanical Stirring | Mechanical Stirring | Mechanical Stirring |

| Valves | Standard 2 (1 Inlet, 1 Outlet) | Standard 2 (1 Inlet, 1 Outlet) | Standard 2 (1 Inlet, 1 Outlet) | Standard 2 (1 Inlet, 1 Outlet) |

| Explosion-proof Device | Selected based on pressure requirements | Selected based on pressure requirements | Selected based on pressure requirements | Selected based on pressure requirements |

| Pressure Gauge | Selected based on bursting disc pressure | Selected based on bursting disc pressure | Selected based on bursting disc pressure | Selected based on bursting disc pressure |

| Temp. Measurement Hole | Standard size 4mm | Standard size 4mm | Standard size 4mm | Standard size 4mm |

| Net Weight | 11.5KG | 14.5KG | 18KG | 22KG |

| Dimensions (L×W×H) | 310×370×370mm | 330×330×545mm | 330×330×545mm | 350×330×590mm |

KT-HPR-B Series Technical Parameters

1. Pressure gauge 2. Temperature sensor 3. Venting/Inlet valve 4. Outlet valve

5. LCD display screen 6. Operating buttons 7. Explosion-proof valve 8. Operating handle

| Model | KT-HPR-B50 | KT-HPR-B100 | KT-HPR-B250 | KT-HPR-B500 |

|---|---|---|---|---|

| Volume | 50mL | 100mL | 250mL | 500mL |

| Material | 304/316 Stainless Steel | 304/316 Stainless Steel | 304/316 Stainless Steel | 304/316 Stainless Steel |

| Design Temp | 270°C | 350°C | 350°C | 350°C |

| Heating/Cooling Rate | ≤3°C/min | ≤3°C/min | ≤3°C/min | ≤3°C/min |

| Design Pressure | 22Mpa | 22Mpa | 22Mpa | 22Mpa |

| Stirring Speed | 0-1800r/min | 0-1800r/min | 0-1800r/min | 0-1800r/min |

| Heating Power | 0.7Kw | 0.7Kw | 0.7Kw | 0.7Kw |

| Heating Method | Modular Electric Heating | Modular Electric Heating | Modular Electric Heating | Modular Electric Heating |

| Stirring Method | Internal Magnetic Stirring | Internal Magnetic Stirring | Internal Magnetic Stirring | Internal Magnetic Stirring |

| Valves | Standard 2 (1 Inlet, 1 Outlet) | Standard 2 (1 Inlet, 1 Outlet) | Standard 2 (1 Inlet, 1 Outlet) | Standard 2 (1 Inlet, 1 Outlet) |

| Explosion-proof Device | Selected based on pressure requirements | Selected based on pressure requirements | Selected based on pressure requirements | Selected based on pressure requirements |

| Pressure Gauge | Selected based on bursting disc pressure | Selected based on bursting disc pressure | Selected based on bursting disc pressure | Selected based on bursting disc pressure |

| Temp. Measurement Hole | Standard size 4mm | Standard size 4mm | Standard size 4mm | Standard size 4mm |

| Net Weight | 10KG | 13KG | 16.5KG | 20KG |

| Dimensions (L×W×H) | 310×370×345mm | 330×330×525mm | 330×330×525mm | 350×330×570mm |

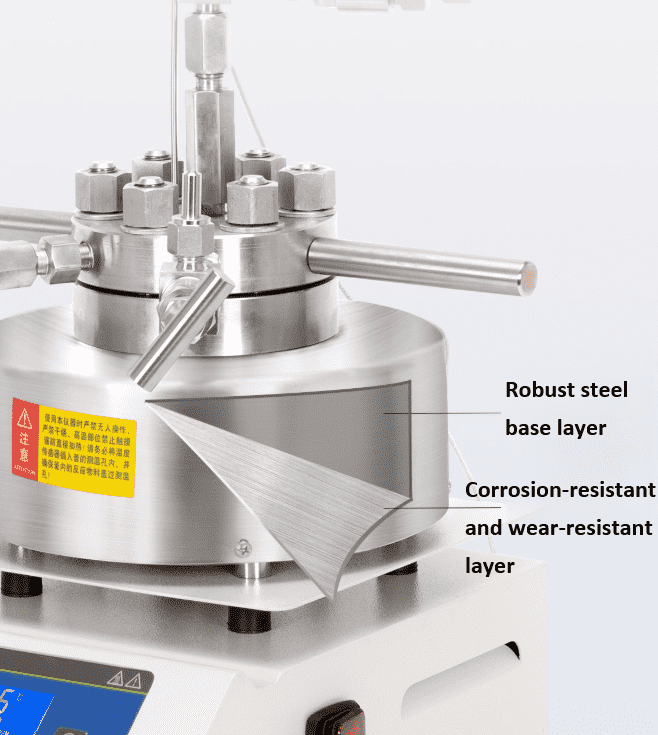

Features

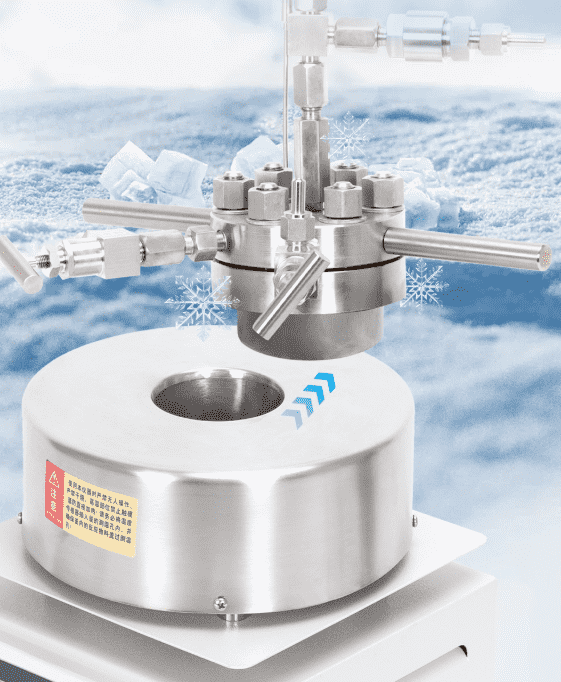

- Reactor independent designing, remove the reactor from the heater more flexible and convenient

- High temperature control accuracy and uniforming heating, guarantee the stable reaction

- Different stirring method available,flexible combination for different reaction processing conditions

- Different reactor material available, meet different reaction temperature requirement

- Pressure gauge and valve port can be designed freely with multi-purpose processing requirement

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

FAQ

What Is A High Pressure Reactor?

What Is An Autoclave Sterilizer?

What Causes An Increase In Pressure Within A High-pressure Reactor?

Increasing pressure inside a pressure reactor can be achieved through various means. One common method is by heating a sealed pressure vessel, where temperature and pressure increase proportionately, impacting reaction kinetics. Alternatively, the reaction occurring inside the vessel can induce pressure, and agitation can accelerate this process.

In situations where heating is unsuitable or insufficient pressure is generated, manual pressurization is possible with a compressed gas source, such as a compressor or a pre-compressed canister of inert gas.

Pressure reactors utilize pressure relief valves to safely regulate and maintain pressure, emphasizing their reliable and safe operation.

How Does An Autoclave Sterilizer Work?

How Does A Pressure Reactor Work?

What Are The Advantages Of Using Autoclave Sterilizers?

What Safety Precautions Should Be Taken When Using Autoclave Sterilizers?

Can All Materials And Items Be Sterilized Using Autoclave Sterilizers?

Are There Different Types Of Autoclave Sterilizers Available?

4.8

out of

5

Incredibly fast delivery! The build quality is exceptional. A fantastic piece of technology that has accelerated our research significantly.

4.9

out of

5

The precision temperature control is a game-changer. It's so versatile and robust, truly outstanding value for the investment.

4.7

out of

5

Arrived sooner than expected. The flexibility in stirring methods and reactor materials is perfect for our diverse lab needs.

4.9

out of

5

A marvel of engineering! The uniform heating and high-pressure capability have revolutionized our chemical synthesis processes.

4.8

out of

5

Durability is top-notch. It handles demanding reactions with ease. The removable reactor design is brilliantly convenient.

4.7

out of

5

Superb quality and surprisingly affordable. The programmable features make complex reactions so much simpler to manage.

4.9

out of

5

Technologically advanced and built to last. The customizable ports and safety valves provide immense peace of mind.

4.8

out of

5

Exceeded all expectations. The precision and reliability of this autoclave reactor are unmatched in its class.

4.7

out of

5

Shipped lightning fast! The stainless steel construction feels incredibly durable and is perfect for high-temperature work.

4.9

out of

5

An absolute workhorse. The combination of advanced features and robust design offers incredible value for any laboratory.

4.8

out of

5

Flawless performance. The adjustable stirring and precise pressure control make it an indispensable tool for our R&D.

4.7

out of

5

Incredible value! The ability to customize the reactor for different applications makes it a versatile and powerful asset.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

Discover the versatility of Stainless High Pressure Reactor - a safe and reliable solution for direct and indirect heating. Built with stainless steel, it can withstand high temperatures and pressures. Learn more now.

Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

This laboratory-scale high-pressure reactor is a high-performance autoclave engineered for precision and safety in demanding research and development environments.

Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

High-pressure lab reactor for precise hydrothermal synthesis. Durable SU304L/316L, PTFE liner, PID control. Customizable volume & materials. Contact us!

High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

Discover the applications of Hydrothermal Synthesis Reactor - a small, corrosion-resistant reactor for chemical labs. Achieve rapid digestion of insoluble substances in a safe and reliable way. Learn more now.

Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

The horizontal autoclave steam sterilizer adopts the gravity displacement method to remove the cold air in the inner chamber, so that the inner steam and cold air content is less, and the sterilization is more reliable.

Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

The desktop fast steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items.

Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

Vertical pressure steam sterilizer is a kind of sterilization equipment with automatic control, which is composed of heating system, microcomputer control system and overheating and overpressure protection system.

Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

Portable autoclave sterilization pressure is a device that uses pressure saturated steam to quickly and effectively sterilize items.

Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

The desktop fast steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items. It efficiently sterilizes surgical instruments, glassware, medicines, and resistant materials, making it suitable for various applications.

Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

The High Temperature Hot Press is a machine specifically designed for pressing, sintering and processing materials in a high temperature environment. It is capable of operating in the range of hundreds of degrees Celsius to thousands of degrees Celsius for a variety of high temperature process requirements.

Square Bidirectional Pressure Mold for Lab Use

Discover precision in molding with our Square Bidirectional Pressure Mold. Ideal for creating diverse shapes and sizes, from squares to hexagons, under high pressure and uniform heating. Perfect for advanced material processing.

Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

Discover Warm Isostatic Pressing (WIP) - A cutting-edge technology that enables uniform pressure to shape and press powdered products at a precise temperature. Ideal for complex parts and components in manufacturing.

Round Bidirectional Press Mold for Lab

The round bidirectional press mold is a specialized tool used in high-pressure molding processes, particularly for creating intricate shapes from metal powders.

915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

915MHz MPCVD Diamond Machine and its multi-crystal effective growth, the maximum area can reach 8 inches, the maximum effective growth area of single crystal can reach 5 inches. This equipment is mainly used for the production of large-size polycrystalline diamond films, the growth of long single crystal diamonds, the low-temperature growth of high-quality graphene, and other materials that require energy provided by microwave plasma for growth.

Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

Get high-quality diamond films with our Bell-jar Resonator MPCVD machine designed for lab and diamond growth. Discover how Microwave Plasma Chemical Vapor Deposition works for growing diamonds using carbon gas and plasma.

Efficient split chamber CVD furnace with vacuum station for intuitive sample checking and quick cooling. Up to 1200℃ max temperature with accurate MFC mass flowmeter control.

Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

Efficiently prepare samples with our Automatic Lab Cold Isostatic Press. Widely used in material research, pharmacy, and electronic industries. Provides greater flexibility and control compared to electric CIPs.

Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

Experience optimal performance with our Water Bath Electrolytic Cell. Our double-layer, five-port design boasts corrosion resistance and longevity. Customizable to fit your specific needs. View specs now.

Custom PTFE Teflon Parts Manufacturer for Acid and Alkali Resistant Chemical Powder Material Scoops

Known for its excellent thermal stability, chemical resistance and electrical insulating properties, PTFE is a versatile thermoplastic material.

Related Articles

Enhancing Safety in Your Laboratory: A Comprehensive Guide to Pressure Reactor Safety

Laboratory safety isn't just about you. Improper preparation and mishandling can cause potential hazards that could be disastrous if left unchecked. It is crucial to take the time to carefully prepare your pressure reactor and lab safety equipment, as even minor problems can escalate quickly when working under pressure.

10 Essential Safety Steps for Pressure Reactor Use in Laboratories

Safety is paramount when conducting chemical reactions under pressurized conditions. It is important to carefully prepare pressure reactors and laboratory safety equipment to prevent potential hazards that, if not controlled, can have catastrophic consequences. In order to ensure the safety of using a pressure reactor, it is important to understand the specifications of the reactor. Become familiar with the chemistry of the reactor material and make sure it is chemically resistant enough to withstand the substances used in the reaction.

How Rotavapor Can Improve Your Distillation Process and Save You Time

A Rotavapor, also known as a rotary evaporator, is a laboratory apparatus used for distillation, purification, and extraction of solvents. It consists of a heating bath, rotation flask, and a condenser, which work together to remove the solvent from a sample.

High Pressure Tube Furnace: Applications, Safety, and Maintenance

Explore the advanced applications, safety measures, and maintenance tips for high pressure tube furnaces. Learn how these furnaces are used in various high-temperature processes and ensure optimal performance and safety.

Basic Laboratory Reaction Equipment

Overview of essential lab equipment for chemical reactions under various conditions.

Laboratory Safety: High Pressure Equipment and Reactors

This article discusses safety measures and precautions for using high pressure equipment and reactors in laboratories, including case studies and detailed usage instructions.

Understanding Isostatic Pressing: Process, Benefits, Limitations, and Applications

Isostatic pressing is a manufacturing process that offers numerous benefits and applications in various industries. It involves subjecting a material to equal pressure from all directions to achieve uniform density and shape. This method is particularly advantageous compared to other production techniques.

Laboratory Jacketed Vessels

Overview of jacketed vessels, their types, and applications in various industries.

Laboratory Safety: Safe Use of High Voltage Equipment

Guidelines for the safe operation of high-pressure equipment in laboratories, including reactors, hydrothermal reactors, autoclaves, and gas cylinders.

Hazards and Safety Precautions of Laboratory Pressure Vessels

An overview of the dangers and safety measures for pressure vessels in laboratory settings.

Basic Mixing Equipment in the Laboratory

Overview of essential laboratory mixing devices and their functionalities.

Molecular Distillation: An Efficient Separation and Purification Technology

Explore the principles, applications, and benefits of molecular distillation in various industries.