Introduction to Atmosphere Furnaces

Welcome to our comprehensive guide on atmosphere furnaces, a pivotal technology in the realm of controlled heat treatment. Atmosphere furnaces play a crucial role in various industrial processes, enabling precise control over heat treatment environments through the use of controlled atmospheres. This guide delves into the fundamental principles of these advanced systems, exploring their key components, diverse types, and intricate operation mechanisms. Whether you're involved in metallurgy, manufacturing, or research, understanding the capabilities and applications of atmosphere furnaces can significantly enhance your processes, ensuring efficiency and quality. Join us as we unravel the complexities of these essential industrial tools and their transformative impact across multiple sectors.

Key Components of Atmosphere Furnaces

Atmosphere furnaces are sophisticated pieces of equipment designed for precise heat treatment processes under controlled atmospheric conditions. These furnaces are essential in various industries, including metallurgy, ceramics, and electronics, where maintaining specific environmental conditions during heating is critical. Here, we delve into the key components that make up an atmosphere furnace and their functions:

1. Heating Chamber

The heating chamber is the core component of an atmosphere furnace, where materials undergo heat treatment. Constructed from high-temperature-resistant materials like refractory metals or ceramics, the chamber is designed to withstand extreme temperatures, typically ranging from 100°C to over 1000°C. The insulation properties of the chamber materials help maintain a uniform temperature distribution, ensuring consistent heat treatment outcomes.

2. Gas Supply System

The gas supply system is crucial for creating and maintaining the desired atmosphere within the furnace. This system includes gas cylinders containing gases such as nitrogen, argon, hydrogen, or a combination of these, along with pressure regulators, flow meters, and distribution lines. The precise control of gas flow rates and mixtures is essential to prevent oxidation, decarburization, or other unwanted chemical reactions during the heating process.

3. Atmosphere Control System

The atmosphere control system is the brain of the furnace, managing the composition, flow, and pressure of gases within the chamber. Advanced systems use computerized controls to adjust parameters in real-time, ensuring that the atmosphere remains consistent throughout the process. This level of control is vital for achieving repeatable and reliable results, especially in applications like annealing, sintering, and brazing.

4. Safety Mechanisms

Safety is paramount in any high-temperature process. Atmosphere furnaces are equipped with multiple safety features to prevent accidents and ensure operator safety. These include high-temperature alarms, emergency shut-off valves, and interlocks that prevent the furnace from operating unless all safety conditions are met. Additionally, the exhaust system is designed to safely remove any byproducts of the heating process, preventing the buildup of hazardous gases.

5. Control Systems

The control systems in an atmosphere furnace include the temperature controller and the atmosphere regulator. The temperature controller uses sensors and feedback loops to maintain the desired temperature within the chamber, adjusting the power to the heating elements as needed. The atmosphere regulator controls the composition and pressure of the atmosphere, ensuring that the environment within the furnace is optimal for the specific heat treatment process.

Applications of Atmosphere Furnaces

Atmosphere furnaces find extensive use in various industries. In metallurgy, they are used for annealing, hardening, and sintering metals to improve their mechanical properties. In the ceramics industry, these furnaces are crucial for firing and glazing processes. Additionally, in electronics, atmosphere furnaces are used for processes like soldering and brazing, where maintaining a controlled environment is essential to prevent oxidation and ensure the integrity of electronic components.

In conclusion, the key components of an atmosphere furnace—the heating chamber, gas supply system, atmosphere control system, safety mechanisms, and control systems—work in harmony to provide a controlled environment for precise heat treatment processes. These components ensure that materials are processed under optimal conditions, leading to high-quality outcomes and efficient production processes.

Types of Atmosphere Furnaces

Atmosphere furnaces are essential tools in various industrial and laboratory settings, designed to heat materials under controlled atmospheric conditions. These furnaces are crucial for preventing oxidation, decarburization, and other unwanted chemical reactions that can occur in the presence of oxygen or other reactive elements. The classification and use of different types of atmosphere furnaces are based on the specific gases used, which can be inert, reducing, or oxidizing in nature.

Inert Gas Atmosphere Furnaces

Inert gas atmosphere furnaces are primarily used to protect materials from oxidation during heat treatment processes. The most common inert gases used in these furnaces are nitrogen (N2) and argon (Ar). Nitrogen is widely used due to its unreactive nature and availability, providing a protective environment where carbon, oxygen, and nitrogen do not react with steel. Argon, another inert gas, is also used to fulfill the criteria of an inert environment.

These furnaces are equipped with precision microprocessor-based temperature controls and energy-efficient insulation to ensure optimal performance and cost savings. They are typically used for applications such as bonding, curing, and heat-treating, where protection from oxidation is critical.

Reducing Atmosphere Furnaces

Reducing atmosphere furnaces use gases that reduce the surface of the metal being treated. Common gases used in these furnaces include hydrogen (H2) and endothermic gas, which is a mixture of nitrogen and hydrogen produced by the reaction of natural gas and air over a heated catalyst. The primary purpose of a reducing atmosphere is to remove oxygen from the metal surface, preventing oxidation and decarburization.

These furnaces are often used in applications where the metallurgical properties of the metal need to be controlled, such as in the production of high-quality steel and other alloys. They are equipped with safety features, especially when hydrogen is used, to prevent explosions and ensure operator safety.

Oxidizing Atmosphere Furnaces

Oxidizing atmosphere furnaces are designed to promote oxidation on the surface of the materials being treated. These furnaces use oxygen-rich atmospheres, which can be pure oxygen or air, to create an oxidizing environment. This type of atmosphere is used in applications where oxidation is beneficial, such as in the production of certain types of ceramics and in some metal finishing processes.

Oxidizing atmosphere furnaces are typically used in specific industrial processes where the formation of oxide layers is desired, either for aesthetic purposes or to enhance the material's properties.

Conclusion

The choice of atmosphere furnace depends on the specific requirements of the application, including the type of material being treated and the desired outcome. Whether it's an inert, reducing, or oxidizing atmosphere, each type of furnace offers unique benefits and is designed to meet specific industrial needs. Selecting the right furnace, equipped with appropriate safety features and precision controls, is crucial for achieving the desired results in heat treatment processes.

Operation and Control Systems

Atmosphere furnaces are integral to processes where controlled environments are crucial for achieving specific material properties. These furnaces operate by creating a sealed chamber where the atmosphere can be precisely manipulated, ensuring that the materials being processed are not exposed to unwanted elements such as oxygen or moisture. This section delves into the step-by-step operation of atmosphere furnaces, the creation of controlled atmospheres, and the role of automation in maintaining precise conditions.

Step-by-Step Guide on How Atmosphere Furnaces Operate

-

Sealed Chamber Setup: The first step in operating an atmosphere furnace is ensuring the tightness of the chamber. This prevents any external air from infiltrating the system, which could compromise the purity of the controlled atmosphere. The chamber is typically made from materials that can withstand high temperatures and resist corrosion from the gases used.

-

Gas Supply Introduction: Once the chamber is sealed, the gas supply system comes into play. This system includes gas cylinders containing gases like nitrogen, argon, hydrogen, or specialized mixtures. These gases are essential for creating the desired atmosphere within the furnace.

-

Gas Flow Control: Pressure regulators and flow meters are used to control the flow of gases into the furnace. These components ensure that the correct amount of each gas is introduced, maintaining the precise composition required for the process.

-

Atmosphere Control: The atmosphere control system is responsible for adjusting the gas flow rates, mixtures, and pressure levels within the furnace. This system uses sensors and automated controls to maintain the desired environment, ensuring consistent and repeatable results.

-

Heating Process: With the controlled atmosphere in place, the furnace is heated to the required temperature. The heating elements within the furnace are designed to provide uniform heat distribution, ensuring that the materials being processed are heated evenly.

-

Process Monitoring: Throughout the heating process, various sensors monitor the temperature, gas composition, and pressure within the furnace. This data is used to make real-time adjustments to the system, ensuring that the process remains within the specified parameters.

-

Cooling and Venting: Once the heating process is complete, the furnace may need to be cooled under controlled conditions. This often involves venting the controlled atmosphere and replacing it with a cooling gas or allowing the chamber to cool naturally.

The Role of Automation in Maintaining Precise Conditions

Automation plays a critical role in the operation of atmosphere furnaces. Modern furnaces are equipped with advanced control systems that use programmable logic controllers (PLCs) and computer interfaces to automate the entire process. These systems can monitor and adjust multiple parameters simultaneously, ensuring that the furnace operates efficiently and consistently.

- Temperature Control: Automated systems can precisely control the temperature within the furnace, making minute adjustments to maintain the desired heat level.

- Gas Composition Control: Sensors continuously monitor the gas composition, and automated valves adjust the flow of gases to maintain the correct mixture.

- Safety Features: Automation also includes safety features such as emergency shut-off systems and alarms that alert operators to any deviations from the specified parameters.

Applications of Atmosphere Furnaces

Atmosphere furnaces are used in a wide range of applications, including:

- Metal Heat Treatment: To improve the hardness, strength, and wear resistance of metals without causing oxidation.

- Ceramic Processing: For sintering and firing ceramics under controlled atmospheres to achieve specific properties.

- Chemical Processing: In the production of certain chemicals where the reaction must occur in a controlled environment.

- Laboratory Research: For experiments that require precise control over the atmospheric conditions.

In conclusion, atmosphere furnaces are sophisticated pieces of equipment that offer precise control over the heating environment. By creating and maintaining controlled atmospheres, these furnaces enable the processing of materials to achieve specific properties and outcomes. The integration of advanced automation systems ensures that these processes are carried out efficiently, safely, and with consistent results.

Applications in Metallurgy

Atmosphere furnaces play a crucial role in metallurgical processes, offering precise control over the environment to enhance the properties of metals. These furnaces are essential in applications ranging from annealing and tempering to hardening and sintering, each process tailored to meet specific metallurgical outcomes.

Annealing

Annealing is a fundamental process in metallurgy used to soften metals or alter their physical properties. By heating the metal to a specific temperature and then slowly cooling it, the material's ductility is increased, reducing its hardness and brittleness. Atmosphere furnaces provide a controlled environment that minimizes oxidation and decarburization, ensuring the metal remains pure and achieves the desired softness. This process is particularly important in the production of wires, sheets, and other forms of metal where flexibility and formability are crucial.

Tempering

Tempering is another critical process that follows hardening. It involves heating the hardened metal to a lower temperature to reduce its brittleness without significantly losing its hardness. This process increases the metal's toughness and ductility, making it more resistant to fractures. Atmosphere furnaces, with their ability to maintain precise temperatures and gas compositions, are ideal for tempering. They help in achieving uniform temperature distribution, which is essential for consistent metallurgical properties across the metal component.

Hardening

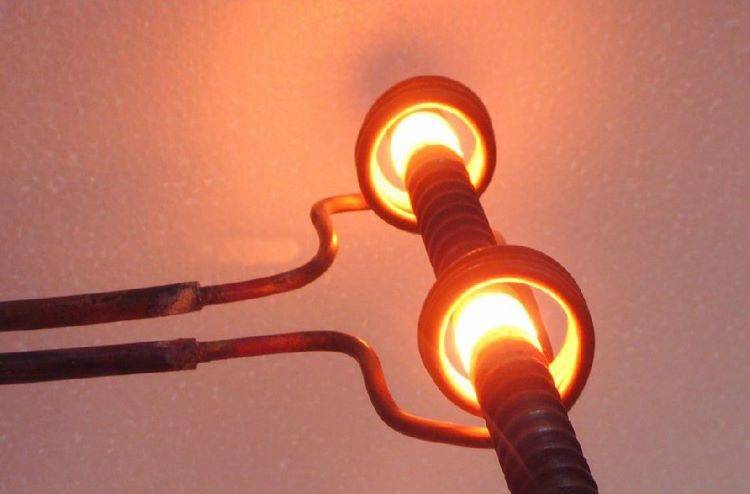

Hardening involves heating the metal to a specific temperature and then quenching it in a suitable medium to increase its hardness and strength. Atmosphere furnaces are used to create the necessary environment for this process, ensuring that the metal is heated uniformly and protected from atmospheric contaminants. For instance, carburizing, a type of hardening process, involves introducing carbon into the metal's surface layer to increase its hardness. This is typically done in an endothermic atmosphere, which is precisely controlled in atmosphere furnaces.

Sintering

Sintering is a process used to create objects from powder particles by heating them to just below their melting point. This process is widely used in the production of metal components, ceramics, and some polymers. Atmosphere furnaces provide a protective atmosphere that prevents oxidation and contamination, ensuring that the powder particles bond correctly and uniformly. The controlled atmosphere also allows for the precise control of the sintering temperature and duration, which are critical for achieving the desired mechanical properties in the final product.

Bright Annealing

Bright annealing is a specialized process used to produce a bright, shiny surface finish on metals without the typical oxidation that occurs during heating. This process is often performed in a pure hydrogen atmosphere or in inert gases like nitrogen or argon. Atmosphere furnaces are designed to maintain these controlled atmospheres, ensuring that the metal remains free from oxidation and achieves a high-quality surface finish. This is particularly important in the production of stainless steel and other high-grade metal products where appearance and corrosion resistance are paramount.

Industrial Applications

The demand for controllable metallurgical outcomes has driven the advancement of heat treatment technology. Modern atmosphere furnaces are equipped with advanced gas pumping systems that can introduce various gases like carbon, nitrogen, and argon to modify the metal's surface properties. For example, gas-pumped furnaces can apply a carburizing finish to improve wear performance, while nitrogen atmospheres enhance the annealing process. These advancements ensure that metallurgical processes are repeatable and produce consistent results, which is essential for industries requiring high precision and quality in their metal components.

In conclusion, atmosphere furnaces are indispensable in metallurgy, offering precise control over the environment to enhance metal properties through various heat treatment processes. Their ability to maintain controlled atmospheres and precise temperatures ensures that metals achieve the desired hardness, ductility, and surface finish, making them vital in a wide range of industrial applications.

Industrial and Research Applications

Atmosphere furnaces are indispensable tools in both industrial and research settings, offering precise control over environmental conditions to enhance material properties and enable advanced manufacturing processes. Their versatility and efficiency make them a cornerstone in several key sectors, including metallurgy, electronics, automotive, aerospace, and glass and ceramics industries.

Metallurgy

In the field of metallurgy, atmosphere furnaces play a pivotal role in various heat treatment processes that significantly influence the mechanical and physical properties of metals. These processes include annealing, tempering, and hardening, which are essential for refining the microstructure of metals to enhance their ductility, hardness, and strength. For instance, steel components undergo carburizing or nitriding in controlled atmospheres to increase their surface hardness and wear resistance, making them suitable for applications in machinery and automotive parts.

Electronics

The electronics industry relies heavily on atmosphere furnaces for the fabrication of semiconductor devices. These furnaces facilitate critical processes such as diffusion, doping, and annealing, which are necessary for creating the intricate structures of integrated circuits and semiconductor chips. By precisely controlling the atmosphere, these furnaces ensure that the electronic components meet the stringent requirements for efficiency, reliability, and performance. For example, the doping process, which introduces impurities to alter the electrical conductivity of semiconductors, is meticulously controlled to achieve the desired electronic properties.

Automotive Industry

In the automotive sector, atmosphere furnaces are extensively used for heat treating various components to enhance their mechanical properties. Parts such as gears, shafts, bearings, and engine components undergo heat treatment in controlled atmospheres to improve their strength, durability, and wear resistance. This not only ensures the longevity of the automotive parts but also contributes to the overall safety and efficiency of vehicles. For instance, the heat treatment of engine valves in a controlled atmosphere can significantly increase their resistance to high temperatures and mechanical stresses.

Aerospace and Defense

The aerospace and defense industries demand materials and components that can withstand extreme conditions, making atmosphere furnaces an essential part of their manufacturing processes. These furnaces are used to produce high-performance components for aircraft engines, turbines, rocket parts, and armor plating. The precise control of the atmosphere during heat treatment ensures that these components meet the stringent requirements for high-temperature resistance, structural integrity, and durability. For example, the heat treatment of titanium alloys in a controlled atmosphere enhances their strength-to-weight ratio, making them ideal for aerospace applications.

Glass and Ceramics

In the glass and ceramics industry, atmosphere furnaces are crucial for heat treatment processes that enhance the physical and mechanical properties of these materials. Glass tempering, ceramic sintering, and annealing are some of the key processes that benefit from the controlled environments provided by these furnaces. The heat treatment in a controlled atmosphere results in superior-quality products with improved strength, hardness, and thermal stability, making them suitable for applications in construction, home appliances, and various other industries. For instance, the tempering of glass in a controlled atmosphere significantly increases its resistance to thermal shock and mechanical impact, making it safer for use in architectural and automotive applications.

Research Applications

In research settings, atmosphere furnaces are used to study the effects of controlled atmospheres on material properties and to develop new materials with specific characteristics. These furnaces are equipped with advanced features such as vacuum pumps, gas flow meters, and needle valves to create and maintain inert atmospheres using gases like argon and nitrogen. In certain applications, hydrogen gas is also used, necessitating explosion-proof safety provisions. The ability to precisely control the atmosphere allows researchers to conduct experiments that simulate extreme conditions and explore the potential of new materials and manufacturing techniques.

In conclusion, atmosphere furnaces are versatile and essential tools in both industrial and research applications. Their ability to provide controlled environments for heat treatment processes enables the production of high-quality materials and components with enhanced properties. As technology advances, the role of atmosphere furnaces is likely to expand, driving innovation and improving the efficiency and performance of various industries.

Advantages and Benefits of Atmosphere Furnaces

Atmosphere furnaces are indispensable tools in various industrial and laboratory settings, offering a range of benefits that enhance production efficiency, reduce costs, and improve product quality. These furnaces operate by maintaining a controlled environment around the material being heated, which can be adjusted to suit specific processing needs such as carburizing, tempering, or annealing. Here, we delve into the key advantages of using atmosphere furnaces.

Energy Efficiency

One of the primary benefits of atmosphere furnaces is their high energy efficiency. These furnaces are designed to minimize heat loss through superior insulation and precise temperature control systems. The use of electric heating elements ensures that heat is generated and distributed evenly within the furnace chamber, reducing the amount of energy required to maintain high temperatures. According to industry statistics, atmosphere furnaces can achieve energy savings of up to 30% compared to traditional heating methods, making them a cost-effective choice for long-term operations.

Cost Reduction

Beyond energy savings, atmosphere furnaces contribute to overall cost reduction in several ways. The precise control over the furnace atmosphere allows for reduced material wastage and improved product consistency. This means fewer defects and rework, directly impacting the bottom line. Additionally, the durability and longevity of atmosphere furnaces, thanks to their robust construction and minimal wear due to controlled environments, mean lower maintenance and replacement costs over time.

Improved Product Quality

The ability to control the atmosphere within the furnace is a game-changer for product quality. By adjusting the gas composition, manufacturers can prevent oxidation, decarburization, and other forms of surface contamination that can degrade the quality of metals and alloys. This is particularly crucial in industries where precision and consistency are paramount, such as aerospace, automotive, and electronics. The result is products with enhanced mechanical properties, longer service life, and superior performance.

Versatility and Flexibility

Atmosphere furnaces are incredibly versatile, capable of handling a wide range of materials and processes. Whether it's heating metals to very high temperatures, conducting precise heat treatments, or creating specific atmospheres for unique applications, these furnaces can adapt to meet diverse industrial needs. This flexibility not only increases their utility but also makes them a valuable investment for any facility looking to expand its capabilities.

Enhanced Safety

Safety is another critical advantage of atmosphere furnaces. The controlled environment reduces the risk of fires and explosions, common hazards in traditional furnaces. Advanced safety features, such as automatic shut-off systems and pressure relief valves, further ensure the protection of both operators and equipment. This not only minimizes the risk of accidents but also complies with stringent safety regulations, safeguarding the reputation and operations of the business.

Environmental Benefits

Lastly, atmosphere furnaces contribute to environmental sustainability. By optimizing energy use and reducing material waste, they lower the carbon footprint associated with industrial processes. The use of inert gases in the furnace atmosphere also helps in minimizing emissions of harmful pollutants, aligning with global efforts to combat climate change and promote cleaner manufacturing practices.

In conclusion, atmosphere furnaces offer a compelling array of advantages that make them a superior choice for modern industrial and laboratory applications. From energy efficiency and cost reduction to improved product quality and enhanced safety, these furnaces are designed to meet the rigorous demands of contemporary manufacturing while paving the way for sustainable and efficient production processes.

Safety and Maintenance

Safety Measures for Atmosphere Furnaces

Atmosphere furnaces are critical pieces of equipment in various industrial and laboratory settings, used for heat treatment processes that require controlled environments. Ensuring the safety of these furnaces is paramount to prevent accidents and maintain operational efficiency. Here are some essential safety measures:

-

Sealing and Pressure Control: The furnace must be well sealed to prevent air intrusion and gas leakage. This ensures the stability of the furnace gas composition and the quality of the heat treatment. Maintaining a positive pressure inside the furnace prevents external air from entering, which could lead to explosions.

-

Uniform Atmosphere: The atmosphere within the furnace should be uniform to ensure consistent heat treatment results. This is achieved by ensuring that the controlled atmosphere circulates evenly within the furnace, maintaining a consistent environment around the workpiece.

-

Engineering Controls: Operate the furnace in a well-ventilated area or within a fume hood to manage any escaping fumes. This is particularly important if the furnace malfunctions, as it can prevent the release of hazardous gases into the workspace.

-

Administrative Controls: Operators must undergo specific safety training for the furnace they are using and should thoroughly read the instrument’s manual. It is crucial to consult with the manufacturer and principal investigator to ensure that experiments align with the furnace’s capabilities. Avoid overheating materials or using containers outside their recommended temperature ranges. Implement an external temperature-controlled power circuit to cut power in case of elevated temperatures.

-

Personal Protective Equipment (PPE): Always wear appropriate PPE when operating an atmosphere furnace. This includes long pants, closed-toe shoes, a lab coat, safety glasses, and heat-resistant gloves. Regularly inspect and replace PPE that shows signs of wear or damage.

Regular Maintenance Practices

Regular maintenance is crucial for the longevity and reliability of atmosphere furnaces. Here are some key maintenance practices:

-

Routine Cleaning: Clean the muffle chamber regularly to remove any residues or buildup that could affect the furnace’s performance. This includes cleaning the heating elements and the interior walls of the furnace.

-

Component Replacement: Inspect and replace any damaged or worn-out components promptly. This includes heating elements, seals, and control systems. Regular replacement of these components prevents unexpected failures and ensures consistent operation.

-

Inspection and Testing: Conduct regular inspections of the furnace for any signs of damage, such as loose wiring, water damage, or heat damage. Perform periodic tests to ensure that all safety features and control systems are functioning correctly.

-

Proper Disposal: Dispose of furnace units that have exceeded their usable lifetime. This ensures that older, potentially unsafe equipment is not used, reducing the risk of accidents and operational issues.

By adhering to these safety measures and maintenance practices, you can ensure the long-term reliability of your atmosphere furnace, prevent operational issues, and maintain a safe working environment.

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Mesh belt controlled atmosphere furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

Related Articles

- Comprehensive Guide to Atmosphere Furnaces: Types, Applications, and Benefits

- Muffle Furnace: Unraveling the Secrets of Uniform Heating and Controlled Atmosphere

- Comparing Laboratory Furnace Features and Specifications: A Guide

- Hydrogen Atmosphere Furnaces: Applications, Safety, and Maintenance

- Controlled Atmosphere Furnace: Comprehensive Guide to Advanced Heat Treatment