Classification of High-Temperature Vacuum Furnaces

Resistance Type High-Temperature Vacuum Furnace

The resistance type high-temperature vacuum furnace employs electric heating wires to generate heat, which is then conducted to the material through radiation. This method is highly versatile, making it applicable to a wide array of materials. At the core of this furnace is the electric heating wire, which is designed to withstand extreme temperatures, often reaching up to 3000°C (5432°F). This capability ensures that the furnace can handle the stringent requirements of high-temperature processes, such as heat treatment, sintering, brazing, and annealing.

One of the standout features of this furnace is its ability to achieve uniform heating across the entire workpiece. This uniformity is crucial for producing high-quality materials with consistent properties, which is essential in industries where precision and reliability are paramount. The vacuum atmosphere maintained within the furnace plays a pivotal role in preventing oxidation, a common issue that can lead to defects and degrade the final product's quality. By eliminating oxygen, the furnace ensures that the materials being processed remain pure and free from contaminants.

In the realm of ultra-high temperature applications, such as those exceeding 2000°C, the resistance type high-temperature vacuum furnace has proven to be indispensable. Despite the technical challenges associated with such extreme conditions, this furnace has carved out a niche by delivering reliable performance and superior results. Its dominance in the market is a testament to its robust design and the meticulous attention to detail in its construction.

The resistance type high-temperature vacuum furnace is not just a tool; it is a cornerstone of advanced material processing technologies. Its ability to operate under vacuum conditions and at such high temperatures makes it an ideal choice for a variety of industrial applications, from electronic component manufacturing to ceramic material sintering and beyond. As the demand for high-performance materials continues to grow, the importance of this furnace in meeting those demands will only increase.

Induction High-Temperature Vacuum Furnace

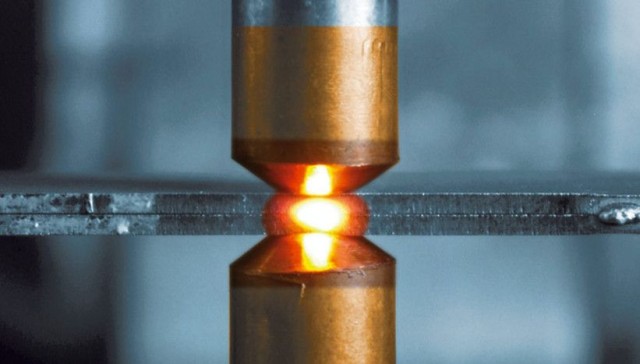

The induction high-temperature vacuum furnace employs electromagnetic induction to generate heat, a process that is particularly effective for the melting and casting of metal materials. This type of furnace operates by creating a high-frequency magnetic field that induces currents within the metal, causing it to heat up rapidly. The furnace is designed to achieve temperatures as high as 2000℃, making it suitable for a wide range of applications.

One of the key advantages of the induction high-temperature vacuum furnace is its ability to operate under a high vacuum environment. This feature is crucial for melting metals that are prone to oxidation or contamination, ensuring the purity and integrity of the final product. The vacuum system, which includes a high vacuum molecular pumping unit, enhances the vacuum degree of the furnace, thereby improving the melting quality and reducing the risk of impurities.

The furnace chamber is typically constructed from stainless steel with a water-cooled design, which not only withstands the high temperatures but also ensures the longevity of the equipment. Additionally, the chamber is equipped with a quartz observation window, allowing operators to monitor the melting process without compromising the vacuum environment. This real-time observation capability is particularly useful for precise control and adjustment during the melting and casting operations.

Induction high-temperature vacuum furnaces are widely used in various industries, including the production of nickel and special steels, precision alloys, active metals, high-temperature alloys, and magnetic materials. They are also ideal for the vacuum precision casting of small parts, making them indispensable in research and industrial settings where high-quality, pure metal components are required.

In summary, the induction high-temperature vacuum furnace stands out for its ability to achieve high temperatures under a controlled vacuum environment, ensuring the purity and precision of metal melting and casting processes. Its advanced design and versatile applications make it a critical tool in both research and industrial production.

Electron Beam High-Temperature Vacuum Furnace

The Electron Beam High-Temperature Vacuum Furnace operates by directing a high-speed electron flow to generate intense heat within a controlled vacuum environment. This technology is particularly adept at delivering precise and localized heat, making it ideal for advanced surface treatment applications. The primary use of this furnace is in the surface treatment of metal materials, where it can achieve uniform heating without the risk of oxidation or contamination, which is often a concern in non-vacuum environments.

One of the standout features of this furnace is its ability to prepare high-quality films. By controlling the electron beam's intensity and direction, it can deposit thin films with exceptional uniformity and adhesion onto various substrates. This capability is crucial in industries such as electronics, where the performance of components can be significantly enhanced by the precise application of protective or functional coatings.

The Electron Beam High-Temperature Vacuum Furnace is also highly versatile, capable of handling a wide range of materials beyond just metals. For instance, it can be used in the sintering of ceramic materials, where the vacuum environment prevents the formation of unwanted compounds and ensures the purity of the final product. This versatility, combined with its high efficiency and precision, makes it a valuable tool in both research and industrial applications.

Other Types of High-Temperature Vacuum Furnaces

In addition to the more common types of high-temperature vacuum furnaces, such as resistance and induction furnaces, there are specialized variants designed for specific applications. Among these, microwave and plasma high-temperature vacuum furnaces stand out due to their unique working principles and application requirements.

Microwave High-Temperature Vacuum Furnaces leverage microwave technology to generate heat within the material itself, rather than externally. This method offers superior control over temperature distribution and can achieve rapid heating rates. Microwave furnaces are particularly advantageous for materials that exhibit strong microwave absorption properties, such as certain ceramics and composites. They are also favored in applications requiring precise temperature control and uniform heating, such as in the sintering of advanced ceramics or the processing of electronic components.

Plasma High-Temperature Vacuum Furnaces utilize plasma, a highly ionized gas, to achieve extremely high temperatures. These furnaces are designed for applications where conventional heating methods are insufficient, such as in the melting of refractory metals or the synthesis of high-purity materials. The plasma's ability to reach temperatures far beyond those achievable by traditional heating elements makes it ideal for processes requiring extreme thermal conditions. Additionally, the high vacuum environment in these furnaces minimizes contamination, ensuring the purity of the processed materials.

Both microwave and plasma furnaces are equipped with advanced temperature control systems, ensuring precise regulation of heating and cooling cycles. They also feature robust vacuum systems to maintain the necessary ultra-high vacuum conditions, preventing unwanted chemical reactions and ensuring the integrity of the processed materials. These specialized furnaces are often customizable, allowing them to be tailored to specific industrial needs, whether for research and development or large-scale production.

Application Scenarios of High-Temperature Vacuum Furnaces

Electronic Components

High-temperature vacuum furnaces are particularly well-suited for the production and processing of electronic components, including Near Field Communication (NFC) devices. These furnaces provide an ideal environment for the precise thermal management required in the fabrication of sensitive electronic elements.

The controlled atmosphere within a high-temperature vacuum furnace ensures that electronic components are not exposed to contaminants that could affect their performance. This is crucial for the production of components like NFC chips, which require high levels of reliability and stability.

Moreover, the ability to maintain a consistent temperature profile within the furnace is essential for the sintering and bonding processes involved in the manufacturing of electronic components. This precision is key to ensuring the integrity and functionality of the final products.

In summary, high-temperature vacuum furnaces offer a superior environment for the production of electronic components, particularly those like NFC devices, by providing a controlled, contaminant-free atmosphere and precise temperature management.

Ceramic Material Sintering

Ceramic material sintering is a critical process in the manufacture of ceramic objects, including pottery. This process involves the use of specialized furnaces such as gas pressure sintering furnaces and graphite vacuum furnaces. These furnaces operate under controlled conditions of high temperature and, in some cases, pressure or electrical currents, to transform raw ceramic materials into dense, strong, and often translucent finished products.

Sintering ceramic materials typically begins with the addition of organic additives to enhance the plasticity of the raw materials, which often have a lower affinity for water compared to traditional clay. As the sintering process progresses, the material undergoes significant shrinkage as the glass phases within it flow and the powdery structure consolidates, reducing porosity. This consolidation is driven by the application of high temperatures, which can be supplemented by external forces like pressure or electrical currents to achieve the desired material properties.

One notable example of ceramic sintering is the transformation of zirconia. Pre-sintered zirconia starts with a monoclinic crystalline structure, characterized by a chalk-like appearance and texture that is easy to mill. Upon exposure to temperatures between 1,100°C and 1,200°C, zirconia undergoes a phase transition to a polytetragonal crystalline state. This transition results in a substantial increase in particle density, strength, and translucency, transforming the material into an extremely hard, dense, and strong ceramic that is challenging to cut even with high-speed tools.

| Sintering Process | Temperature Range | Material Transformation |

|---|---|---|

| Initial Stage | Below 1,100°C | Monoclinic structure, chalk-like appearance |

| Transition Stage | 1,100°C - 1,200°C | Polytetragonal structure, increased density and strength |

| Final Stage | Above 1,200°C | Extremely hard, dense, and strong ceramic |

The sintering process not only enhances the physical properties of ceramic materials but also plays a crucial role in shaping them into complex 3D forms through techniques like hot isostatic pressing. This method allows for the creation of intricate shapes with uniform density and strength, making it indispensable in various industrial applications.

High-Temperature Processes

High-temperature processes encompass a broad range of applications that require precise control and maintenance of elevated temperatures. These processes are facilitated by specialized equipment such as manual high-temperature hot presses and vacuum furnaces, which are often lined with ceramic fiber to ensure thermal efficiency and durability.

Key Applications in High-Temperature Processes

-

Ceramic Material Sintering:

- Vacuum furnaces with ceramic fiber lining are crucial for sintering ceramic materials, ensuring uniform heating and minimal thermal degradation.

- Examples: Gas pressure sintering furnaces and graphite vacuum furnaces are commonly used for this purpose.

-

Metal Heat Treatment:

- High-temperature processes are integral to metal heat treatment, including annealing, quenching, and tempering, which enhance the mechanical properties of metal parts.

- Equipment: Vacuum heat treatment furnaces are preferred for their ability to maintain a controlled environment and prevent oxidation.

-

Surface Coating:

- Vacuum furnaces are employed for surface coating under vacuum conditions, improving the wear and corrosion resistance of materials.

- Process: The vacuum environment ensures uniform coating and eliminates impurities.

-

Powder Metallurgy:

- Vacuum furnaces play a vital role in pressing and sintering metal powders to produce high-quality metal products.

- Advantages: The vacuum conditions facilitate precise control over the sintering process and enhance the final product's properties.

Benefits of Ceramic Fiber Lining

- Thermal Efficiency: Ceramic fiber lining provides excellent insulation, reducing heat loss and improving energy efficiency.

- Durability: The lining is resistant to high temperatures and thermal shock, ensuring the longevity of the equipment.

- Uniform Heating: It helps in achieving uniform temperature distribution within the furnace, which is crucial for consistent process outcomes.

In summary, high-temperature processes rely on specialized equipment like manual hot presses and vacuum furnaces with ceramic fiber lining to achieve precise and efficient thermal operations across various industries.

Precise Metal Melting and Casting

Vacuum induction melting furnaces and vacuum brazing furnaces are pivotal in achieving precise metal melting and casting processes. These specialized furnaces operate under vacuum conditions, which significantly reduce the risk of oxidation and contamination, ensuring the purity and integrity of the final product.

Key Features and Applications:

-

Vacuum Induction Melting Furnaces: These furnaces use electromagnetic induction to generate heat, making them ideal for melting and casting metal materials. The absence of atmospheric oxygen prevents oxidation, which is crucial for high-purity alloys used in aerospace and medical industries.

-

Vacuum Brazing Furnaces: These furnaces are designed for brazing, a process that joins metals using a filler metal with a melting point higher than that of the base metal. Vacuum brazing ensures strong, leak-proof joints, making it essential in automotive and aerospace engineering.

Advantages of Vacuum Processes:

| Advantage | Description |

|---|---|

| Purity | Reduces oxidation and contamination, ensuring high-purity metal alloys. |

| Precision | Allows for precise temperature control, essential for intricate casting designs. |

| Uniformity | Ensures uniform heating and cooling, leading to consistent material properties. |

| Environmental Benefits | Minimizes emissions and waste, contributing to a cleaner production process. |

In summary, the combination of vacuum induction melting and brazing furnaces offers unparalleled precision and quality in metal melting and casting, making them indispensable in industries requiring high-integrity metal components.

Metal Heat Treatment

Vacuum heat treatment furnaces are indispensable tools in the metalworking industry, playing a crucial role in enhancing the physical and mechanical properties of metal parts. These furnaces are specifically designed to perform a range of thermal processes, including annealing, quenching, and tempering, which are essential for modifying the microstructure of metals to achieve desired characteristics such as hardness, ductility, and strength.

The primary advantage of using vacuum furnaces for heat treatment is the controlled environment they provide, which minimizes oxidation and contamination. This is particularly important for high-value components in industries such as aerospace, automotive, and medical devices, where precision and material integrity are paramount.

| Process | Description |

|---|---|

| Annealing | Softens the metal, improving ductility and reducing internal stresses. |

| Quenching | Rapidly cools the metal to increase hardness and strength. |

| Tempering | Relieves stresses from quenching, improving toughness without losing hardness. |

Vacuum heat treatment is also versatile, applicable to a wide array of materials, from tool steels and stainless steels to titanium alloys and superalloys. This versatility makes it a cornerstone in the manufacturing processes of many advanced industries, ensuring that components meet rigorous performance standards.

Drying and Quality Improvement

Vacuum drying furnaces play a crucial role in the removal of water and other volatile substances from various materials, thereby enhancing their overall quality and performance. Unlike conventional drying methods, vacuum drying operates under reduced pressure, which significantly lowers the boiling point of water, allowing for more efficient and controlled moisture extraction.

This method is particularly advantageous for materials that are sensitive to high temperatures or prone to oxidation, as the vacuum environment minimizes these risks. For instance, in the processing of pharmaceuticals, electronics, and advanced ceramics, vacuum drying ensures that the final products are free from residual moisture, which can otherwise lead to defects such as cracking, delamination, or reduced efficacy.

Moreover, the controlled environment of a vacuum drying furnace allows for precise temperature and pressure adjustments, enabling the optimization of drying times and conditions for different materials. This adaptability makes vacuum drying furnaces indispensable in industries where product consistency and quality are paramount.

| Advantage | Description |

|---|---|

| Efficient Moisture Removal | Lower boiling point under vacuum enhances water removal efficiency. |

| Temperature Sensitivity | Ideal for materials that cannot withstand high temperatures. |

| Minimized Oxidation | Vacuum environment prevents oxidation, crucial for sensitive materials. |

| Precise Control | Adjustable temperature and pressure settings for optimal drying conditions. |

Vacuum drying furnaces are thus not just tools for drying but essential instruments for quality improvement, ensuring that materials meet the stringent standards required by modern industries.

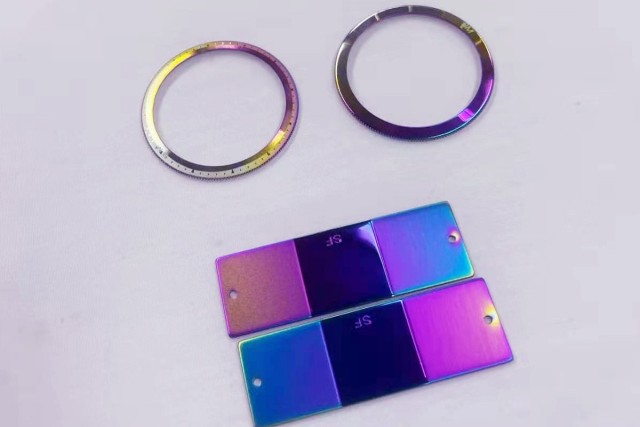

Surface Coating

The vacuum coating furnace is a specialized piece of equipment designed to apply protective coatings to materials under vacuum conditions. This process significantly enhances the wear and corrosion resistance of the coated materials, making them more durable and reliable in various industrial applications.

Key Techniques in Vacuum Coating

-

Physical Vapor Deposition (PVD): This technique involves evaporating the coating material and condensing it onto the substrate. Common methods include:

- Sputtering: Uses argon ions to knock atoms from a target material, which then deposit onto the substrate.

- Evaporation: Heats the coating material until it vaporizes, with the vapor then condensing on the substrate.

-

Chemical Vapor Deposition (CVD): Involves the chemical reaction of gaseous compounds to produce a solid deposit on the substrate. This method is particularly effective for creating complex coatings.

Advantages of Vacuum Coating

- Enhanced Surface Properties: Coating materials under vacuum conditions ensures a uniform and dense layer, improving mechanical properties such as hardness and wear resistance.

- Corrosion Protection: The absence of oxygen and other reactive gases in the vacuum environment prevents oxidation, offering superior corrosion resistance.

- Precision and Control: Advanced temperature and pressure control systems ensure precise application of coatings, tailored to specific material requirements.

Applications of Vacuum Coating

| Industry | Application |

|---|---|

| Aerospace | Protective coatings on aircraft components to withstand extreme conditions. |

| Automotive | Enhanced durability of engine parts and exterior components. |

| Electronics | Thin film coatings on semiconductors and other electronic components. |

| Medical | Biocompatible coatings on medical devices to prevent corrosion and improve longevity. |

Vacuum coating furnaces play a crucial role in various industries by providing advanced surface treatments that enhance the performance and lifespan of materials.

Metal Melting and Purity Improvement

The vacuum melting furnace plays a pivotal role in the metallurgical process, particularly in the melting and casting of metal materials under vacuum conditions to enhance their purity and quality. This method is essential for producing metals with high purity levels, as the resulting properties of the metal are significantly influenced by the concentration of impurities. These impurities can negatively impact the final product's characteristics, making it crucial to prevent their formation during the melting process.

One of the primary advantages of using a vacuum melting furnace is the reduction of impurities through the prevention of chemical reactions with the atmosphere and furnace walls. Additionally, the dissolution of crucible material components is minimized, further contributing to the purity of the melt. To achieve a homogeneous material, it is vital to ensure a uniform distribution of alloying components within the melt volume, which is facilitated by controlling the melting time.

Among the various techniques for heating and melting metals, induction furnaces are widely utilized due to their ability to provide non-contact control of melt mixing through an electromagnetic field, temperature, and surface shape. For high-purity materials, induction furnaces equipped with cold crucibles are preferred over traditional ceramic crucibles. These cold crucible induction furnaces are extensively used in industries such as aerospace, automotive, and medical, as well as in semiconductor manufacturing for photovoltaic purification and silicon crystallization. The use of a cold crucible, which remains transparent to the electromagnetic field due to air gaps, allows for strong compression of the melt, resulting in semi-levitation. This process reduces contamination of the melt with crucible material.

The melting and refining process involves several critical steps to ensure the highest purity levels. Initially, the material containing all inactive alloying elements is melted, with the presence of carbon playing a dual role: deoxidizing the melt and providing stirring. In contrast, ultra-low-carbon alloys require excess oxygen to fully decarburize during the melting period. To avoid intense boiling and splashing, argon gas is introduced at a controlled pressure. During the refining period, adequate stirring of the molten pool is essential to ensure uniformity in the metal's composition and facilitate various metallurgical reactions. The temperature during this phase must be carefully managed; while higher temperatures can enhance reaction rates, excessively high temperatures can lead to increased oxygen content in the metal and other adverse effects. The vacuum level should be optimized to the highest achievable value, typically ranging from 1.33 to 0.13 N/m, to leverage the benefits of vacuum smelting. Volatile alloying elements are added only when necessary, and active alloying components are introduced after full deoxidation to adjust the melt pool temperature for pouring.

The pouring process is equally critical, as it directly impacts the final product's quality. Accurate control of the pouring temperature ensures that the liquid metal has good mobility without causing overheating, which could lead to mold wall damage and increased secondary inclusions. Measures to prevent slag and other impurities from entering the mold, such as the use of slag plates and foam ceramic filters, are essential. Additionally, methods like heat insulation caps and induction heating are employed to fill ingot shrinkage holes effectively.

In summary, the vacuum melting furnace is a sophisticated tool in metallurgy, offering significant advantages in achieving high purity and quality in metal materials. By meticulously controlling various parameters such as temperature, vacuum levels, and the addition of alloying elements, this technology ensures the production of metals with superior properties tailored to specific industrial applications.

Metal Welding

Vacuum welding furnaces are specialized tools designed to weld metal materials under vacuum conditions, thereby significantly enhancing the quality and efficiency of the welding process. The absence of atmospheric oxygen in these furnaces prevents oxidation, which is a common issue in traditional welding methods, leading to cleaner and stronger welds. This makes vacuum welding furnaces particularly advantageous for applications where high precision and material integrity are critical, such as in aerospace, automotive, and electronics industries.

Under vacuum conditions, the metal's surface remains free from contaminants, ensuring that the weld interface is pristine. This results in superior mechanical properties of the welded joint, including increased strength and durability. Additionally, the vacuum environment minimizes the risk of porosity and inclusions, which are common defects in conventional welding methods. These benefits collectively contribute to the production of high-quality, reliable metal components that meet stringent industry standards.

Furthermore, the efficiency of vacuum welding furnaces is enhanced by their ability to achieve rapid heating and cooling cycles. This not only reduces the overall processing time but also minimizes thermal distortion of the metal parts. The controlled environment provided by these furnaces allows for precise temperature management, ensuring that the welding parameters are optimized for each specific material and application. This level of control is essential for achieving consistent and reproducible results, which are crucial for industrial manufacturing processes.

In summary, vacuum welding furnaces offer a superior method for metal welding by eliminating common welding defects and ensuring high-quality, reliable welds. Their application in various industries underscores their importance in modern manufacturing processes.

Powder Metallurgy

The Vacuum Powder Metallurgy Furnace is a specialized piece of equipment utilized for pressing and sintering metal powders under vacuum conditions. This process is pivotal in the production of high-quality metal products, offering precision and consistency that is difficult to achieve through traditional manufacturing methods.

Key Advantages of Vacuum Powder Metallurgy

-

Material Efficiency: By eliminating the need for subtractive processes, powder metallurgy significantly reduces material waste, thereby lowering the overall cost of the final product.

-

Unique Material Production: This method enables the creation of materials that are otherwise impossible to obtain through conventional melting or forming techniques. For instance, tungsten carbide, a material widely used in industrial tools, is produced by bonding tungsten carbide particles with cobalt.

-

Precision and Accuracy: The sintering process, which involves heating the pressed metal powder to just below the melting point of the primary metal, ensures that the powder particles bond together with high precision. This results in parts that are both dimensionally accurate and structurally robust.

Applications in Industry

Powder metallurgy is not limited to a single type of product. It finds extensive use in various industrial applications, including:

-

Tools and Cutting Equipment: The production of tungsten carbide tools, which are essential for cutting and forming other metals.

-

Electrical Components: The manufacture of sintered filters, porous oil-impregnated bearings, and electrical contacts.

-

Structural Parts: The creation of gears, bushings, and bearings, which are integral components in machinery and automotive industries.

Historical Context

The origins of powder metallurgy can be traced back to ancient times, where it was used to produce household items and tools. With the advent of the first industrial revolution, it evolved into a method for mass-producing products and parts, a role it continues to play today with the added benefits of modern technological advancements.

In summary, the Vacuum Powder Metallurgy Furnace is a cornerstone in the production of high-quality metal products, leveraging the advantages of material efficiency, precision, and the ability to create unique materials that drive various industries forward.

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- Comprehensive Guide to Vacuum Hot Press Furnace Application

- The Physics of Perfection: Why a Vacuum Is the Material Scientist's Most Powerful Tool

- From Dust to Density: The Microstructural Science of Hot Pressing

- The Unseen Physics of Perfection: Mastering Heat, Pressure, and Time

- The Physics of Permanence: How Hot Presses Forge the Modern World