Introduction to Pressed Pellet Technique

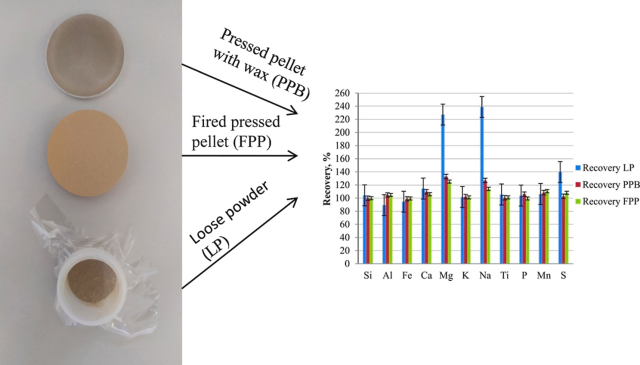

Pressed pellet technique is a widely used method for preparing solid samples for analysis. The technique involves compressing a powdered sample into a pellet form using a laboratory press. Pelletizing the sample is critical in spectroscopic analysis, as it increases the sample's density and improves the signal-to-noise ratio. The pressed pellet technique is essential in various industries, including mining, pharmaceuticals, and environmental science. The pellets produced by the technique have a consistent size, shape, and density, making them ideal for use in XRF, XRD, and IR analysis. The pelletization process is highly efficient and reduces sample preparation time, making it an indispensable tool for laboratory analysts.

Table of Contents

Importance of Material Utilization Efficiency

Efficient material utilization is essential for reducing waste and conserving resources, both of which are important for sustainable development. The pressed pellet technique is a valuable tool for improving material utilization efficiency. By providing accurate and detailed information about a material's properties, this technique can help researchers optimize its usage and reduce waste.

Maximizing Information Extraction from Samples

The pressed pellet technique involves compressing a sample of the material under high pressure to create a uniform pellet shape that can be easily analyzed. This technique is particularly useful for analyzing small quantities of materials, as it allows for accurate measurements of the sample's elemental composition, crystal structure, and other properties. By using this technique, researchers can maximize the amount of information they can extract from a given sample, which is critical for improving material utilization efficiency.

Optimizing Material Usage

By using the pressed pellet technique, researchers can better understand the properties of a material and optimize its usage. For example, they can determine the optimal temperature and pressure conditions for a particular material, which can reduce the amount of energy required for its production and processing. The pressed pellet technique can also help identify impurities or defects in a material, which can be removed to improve its performance and reduce waste.

Sustainable Development

As sustainability becomes an increasingly important issue, methods like the pressed pellet technique will play an important role in ensuring that we use our resources in the most efficient and responsible way possible. By reducing waste and conserving resources, we can minimize our impact on the environment and promote sustainable development.

In conclusion, the importance of material utilization efficiency cannot be overstated. The pressed pellet technique is a valuable tool for improving material utilization efficiency by providing accurate and detailed information about a material's properties, optimizing its usage, and promoting sustainable development.

Factors Affecting Pellet Shape and Density

The shape and density of a pellet are critical factors that affect the accuracy and precision of the analysis when using the pressed pellet technique. In this section, we will discuss the different factors that can impact pellet shape and density.

Particle Size

The particle size of the material is an important factor that affects pellet shape and density. For optimal results, the sample should be ground to a particle size of <50µm, although <75µm is also acceptable. This is because small particle sizes enable better binding of the sample under pressure, which results in more accurate analysis.

Pressure

The pressure applied during the pelletizing process is another critical factor that affects pellet shape and density. The hydraulic press used for pressing the material needs to apply enough pressure to ensure that the binder recrystallizes and the sample is completely compressed. Most samples require pressing for 1-2 minutes under 25-35T of pressure to ensure no void spaces are present in the pellet.

Thickness

The thickness of the pellet is also crucial for effective analysis. If the pellet is too thick, the X-rays will not be able to penetrate it up to a certain point. The sample must be infinitely thick to the X-rays to ensure accurate analysis. Therefore, it is important to ensure that the pellet thickness is optimized to enable the X-rays to penetrate the sample.

Sample Composition

The composition of the sample can also impact the shape and density of the pellet. The nature of the material itself, particle shape, and the particle size distribution can all affect the shape and density of the pellet. It is important to consider these factors when preparing samples for analysis using the pressed pellet technique.

Pellet Die Size

The size of the pellet die used for pressing the sample can also impact pellet shape and density. Pellet dies usually have a maximum rated load that limits the pressure to under 1000 MPa. Therefore, there is a trade-off between the size of the required pellet and the compaction pressure that can be achieved. To achieve a pressure of 250 MPa, for example, a 5 mm die would only require 0.5 tonnes of load, while a 40 mm die would require over 30 tonnes of load.

In conclusion, the factors that affect pellet shape and density are critical to obtaining accurate and reliable analysis results when using the pressed pellet technique. Particle size, pressure, thickness, sample composition, and pellet die size are all important factors to consider when preparing samples for analysis. By optimizing these factors, the material utilization efficiency can be improved, resulting in more accurate and reliable analysis.

Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP)

Pressed pellet techniques, such as Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP), are widely used in the production of high-quality metal components. Both CIP and HIP are isostatic pressing techniques used in powder metallurgy to produce dense and homogeneous materials.

Cold Isostatic Pressing (CIP)

In CIP, powdered metal is placed inside a flexible mold made of rubber, urethane, or PVC. The assembly is then pressurized hydrostatically in a chamber, usually using water, with pressures ranging from 400 to 1000MPa. The powder gets compacted, and the green compact is taken out and sintered. CIP has the advantage of producing parts where the high initial cost of pressing dies cannot be justified or when very large or complex compacts are needed.

CIP is commonly used for parts that do not require high precision in the sintered state and are too large to be pressed in uniaxial presses. It is a very simple process capable of producing high-integrity billets or preforms that exhibit little distortion or cracking when fired. The main advantage of isostatic pressing is the absence of wall friction as pressure is being applied from all directions.

Hot Isostatic Pressing (HIP)

On the other hand, in HIP, a metal powder is stressed using inert gas inside a metal container with a high melting point. Pressure of 100MPa at 1000oC is used, and the inert gas acts as the pressuring media. HIP is relatively expensive but produces compacts with essentially 100% density, good metallurgical bonding among the particles, and good mechanical properties.

HIP is often used to make super alloy components for the aerospace industry, as well as for the densification of WC cutting tools and PM tool steels. It is also used to close internal porosity and improve properties in superalloy and Ti alloy castings for the aerospace industry.

Advantages of Isostatic Pressing

Both CIP and HIP have significant advantages over traditional manufacturing methods. They are able to produce materials with higher densities, improved mechanical properties, and better resistance to wear and corrosion. Additionally, these techniques are highly versatile and can be used to produce a wide range of materials, including ceramics, metals, and polymers.

One of the main benefits of using pressed pellet techniques is that they significantly improve material utilization efficiency. By compressing the sample into a uniform shape, these methods reduce the amount of waste material produced during the manufacturing process. This is particularly important for expensive or rare materials, as it allows for greater use of the available resources.

In summary, isostatic pressing techniques such as CIP and HIP offer a highly effective way to improve material utilization efficiency. These methods produce materials with improved properties and can be used with a wide range of materials. By reducing waste and maximizing the use of available resources, these techniques offer significant benefits for both manufacturers and researchers in a variety of fields.

Related Products

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

Related Articles

- Operating of Automatic Lab xrf Pellet Press

- Manual Hydraulic Pellet Press: An Efficient Tool for Spectral Analyses Preparation

- Comprehensive Guide to Manual Hydraulic Pellet Press

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- Fully automatic tablet press operating steps and replacement accessories