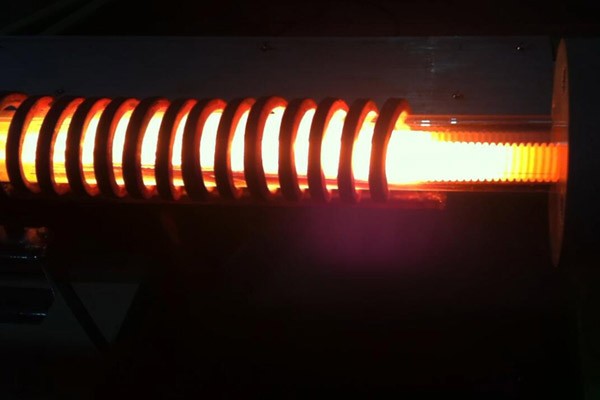

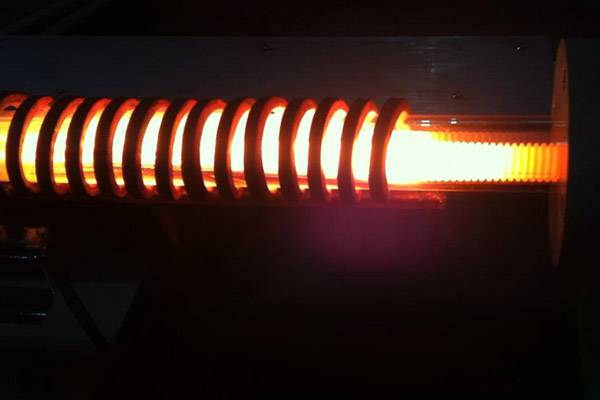

Understanding Batch Vacuum Furnaces

Batch vacuum furnaces are integral to various thermal processes, offering versatility and precision in heat treatment applications. These furnaces are adept at handling diverse materials, providing annealing, brazing, carburizing, and hardening capabilities.

Versatile Heat Treatment Options

Vacuum furnaces facilitate a wide array of heat treatment processes, including annealing, brazing, sintering, tempering, and hardening. Their flexibility allows manufacturers to process various materials with distinct heat treatment requirements efficiently.

Energy Efficiency

Designed with energy efficiency in mind, vacuum furnaces employ advanced insulation materials to minimize heat loss. Additionally, sophisticated control systems optimize energy consumption, reducing operating costs and environmental impact.

Applications of Vacuum Furnaces

Primarily utilized in the aerospace and automotive industries, vacuum furnaces play a crucial role in multiple processes, such as brazing, aging, and solution heat treating. They ensure minimal oxidation and contamination during heat treatment, maintaining the integrity of the materials.

Evolution of Vacuum Furnaces

The origins of vacuum furnaces trace back to the 1930s when they were initially used for annealing and melting titanium sponge materials. Early iterations were hot wall vacuum furnaces and lacked diffusion pumps, unlike modern cold wall vacuum furnaces.

Configurations and Components

Electrically heated batch vacuum furnaces are available in various configurations to suit different thermal processing needs. Basic styles include front and top-loading single chamber furnaces for high-temperature applications. These furnaces feature graphite or ceramic insulation packages and evacuation systems comprising rough pumps, boosters, and diffusion pumps.

Modular Design and Quenching Capabilities

With a modular design, batch vacuum furnaces offer versatility in configuration. Independent quench chambers can be added to the heating chamber, allowing for customization based on specific requirements. Quenching mediums may include gas, pressurized gas, and/or oil, with temperature and vacuum level isolation achieved through internal vacuum doors.

Batch vacuum furnaces stand as indispensable tools in modern manufacturing, providing precise control over heat treatment processes while ensuring the integrity and quality of materials across diverse industries.

Options for Vacuum Furnaces

Detailing the range of options available for vacuum furnaces at the ordering stage, including advanced software, data loggers, and state-of-the-art digital controllers for enhanced control and data logging capabilities. Discuss different pumps, vacuum systems, and cooling systems tailored to specific requirements.

Custom Vacuum Furnace Engineering

Would you describe your requirements for vacuum furnace systems as “nonstandard” or “unconventional”? Perfect. Our custom vacuum furnaces are engineered for your specific project – no matter how “out there” it may be.

What are some options for vacuum furnace engineering?

-

Designed for Multiple Processes: Our vacuum furnaces are versatile, designed to accommodate various processes tailored to your needs.

-

Vertical or Horizontal Loading: Choose the loading orientation that best suits your workflow and space constraints.

-

Range of Shapes and Sizes: From compact designs to large-scale systems, we offer a range of configurations to fit your application.

-

Multiple Hot Zone Options: Select the hot zone configuration optimized for your specific heating requirements.

-

Manual or Automatic Flow Controls: Customize the level of automation based on your operational preferences and requirements.

Examples of Previous Custom Vacuum Furnace Work

Advanced Automation and Control:

Our vacuum furnaces are equipped with advanced automation and control systems, empowering you with precise process management and monitoring capabilities. Our user-friendly interface allows you to effortlessly program and adjust various parameters, ensuring optimal performance and efficiency. With real-time data and diagnostics, you can make informed decisions, detect anomalies, and optimize your production processes for maximum output.

Energy Efficiency and Sustainability:

Our vacuum furnace systems are designed with energy efficiency and sustainability in mind. By optimizing thermal insulation and integrating energy-saving features, we minimize heat loss and reduce overall energy consumption. Additionally, our systems are engineered for durability and reliability, ensuring long-term operational efficiency with minimal environmental impact.

Vacuum Pump Options

Vacuum Pump Technologies:

-

Mechanical Pumps: These pumps rely on mechanical means to create a vacuum by trapping and exhausting gas molecules.

-

Cryogenic Pumps: Operating at extremely low temperatures, cryogenic pumps condense gases to achieve high vacuum levels.

-

Turbo Pumps: Utilizing high-speed rotating blades, turbo pumps efficiently evacuate gas molecules from the vacuum chamber.

-

Ion Pumps: Ion pumps use electrically charged particles to capture and remove gas molecules, achieving ultra-high vacuum levels.

Factors Affecting Vacuum Performance:

Several factors influence the ultimate vacuum level and performance of vacuum pumps, including:

-

Material Composition: The composition of materials introduced into the chamber affects vacuum performance.

-

Cleanliness: The cleanliness of the system's components and surfaces impacts vacuum quality.

-

Desorption Rate: The rate at which gases are released from inner surfaces affects vacuum stability.

-

Outgassing: Gases released from samples or other items introduced into the chamber influence vacuum conditions.

-

Leakage Rate: The rate of air leakage from the furnace or oven affects overall vacuum integrity.

Vacuum Furnace Options and Applications

The Vacuum Furnace range is available with a number of different options at the ordering stage, including advanced software, data loggers, and state-of-the-art digital controllers. These facilitate a higher level of control over the operation of the vacuum furnace and provide full data logging capabilities. In addition, in some cases, different pumps, vacuum systems, and cooling systems can be supplied to meet specific requirements.

Applications in Research and Development

Highlighting the crucial role of vacuum furnaces in research and development laboratories for studying material behavior under controlled thermal conditions. Emphasize their contribution to the development of new alloys, advanced materials, and innovative heat treatment processes.

Vacuum furnaces are highly valuable tools in research and development laboratories, playing a vital role in studying the behavior of materials under controlled thermal conditions. These furnaces enable scientists and engineers to explore the properties and characteristics of various materials, leading to the development of new alloys, advanced materials, and innovative heat treatment processes.

Advancements in Alloy Development

One of the key applications of vacuum furnaces in research and development is the development of new alloys. By subjecting different materials to controlled thermal conditions, researchers can study the effects of temperature, pressure, and other factors on the composition and structure of alloys.

Vacuum furnaces facilitate the melting and refining of metals under vacuum or with protective gas, allowing for precise control over the alloy's composition. This tight control ensures the production of high-quality alloys with desired properties, such as enhanced strength, corrosion resistance, and heat resistance.

By harnessing the capabilities of vacuum furnaces, researchers have been able to create advanced alloys that are used in various industries. For example, aerospace companies utilize vacuum furnace technology to develop lightweight yet strong alloys for aircraft components. These alloys offer improved fuel efficiency and durability, contributing to the advancement of the aerospace industry.

Exploration of Advanced Materials

In addition to alloy development, vacuum furnaces are instrumental in the study of advanced materials. Advanced materials refer to materials that possess unique properties or characteristics beyond those of traditional materials.

Through the use of vacuum furnaces, researchers can subject advanced materials to specific thermal conditions to understand their behavior and properties. This knowledge is crucial for optimizing the performance of these materials and identifying potential applications in various industries.

For instance, in the field of electronics, researchers utilize vacuum furnaces to study the behavior of semiconductors under controlled thermal environments. This research aids in the development of more efficient and reliable electronic devices.

Similarly, in the medical field, vacuum furnace technology is employed to explore the behavior of biomaterials, such as biocompatible alloys and ceramics. This research contributes to the development of innovative medical implants and devices that improve patient outcomes.

Innovative Heat Treatment Processes

Vacuum furnaces also play a crucial role in the development of innovative heat treatment processes. Heat treatment is a method used to alter the physical and mechanical properties of materials through controlled heating and cooling.

By utilizing vacuum furnaces, researchers can precisely control the temperature, pressure, and atmosphere during the heat treatment process. This level of control enables the development of novel heat treatment techniques that can enhance the properties of materials in unprecedented ways.

For example, vacuum heat treatment can be used to improve the hardness, wear resistance, and fatigue strength of various metals. This process involves heating the material in a vacuum environment, followed by controlled cooling. The absence of oxygen and other impurities allows for optimal material properties, resulting in components with superior performance.

Furthermore, vacuum carburizing is a specialized heat treatment process that involves introducing carbon into the surface of a material to increase its hardness. This process, enabled by vacuum furnaces, has revolutionized the production of gears, bearings, and other high-performance components in industries such as automotive and machinery.

Conclusion

Vacuum furnaces have revolutionized research and development in the field of materials science. Their ability to create precise and controlled thermal environments enables scientists and engineers to study the behavior of materials, leading to advancements in alloy development, exploration of advanced materials, and the development of innovative heat treatment processes.

By harnessing the capabilities of vacuum furnaces, researchers have been able to push the boundaries of material science, resulting in the creation of new alloys with enhanced properties, the discovery of advanced materials with unique characteristics, and the development of cutting-edge heat treatment techniques. These advancements have had a significant impact on various industries, driving innovation and progress.

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Multi-zone Laboratory Tube Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

Related Articles

- The Art of the Void: When Precision Matters More Than Power

- Materials Science with the Lab Vacuum Furnace

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Why Your Brazed Joints Fail: The Truth About Furnace Temperature and How to Master It