Introduction

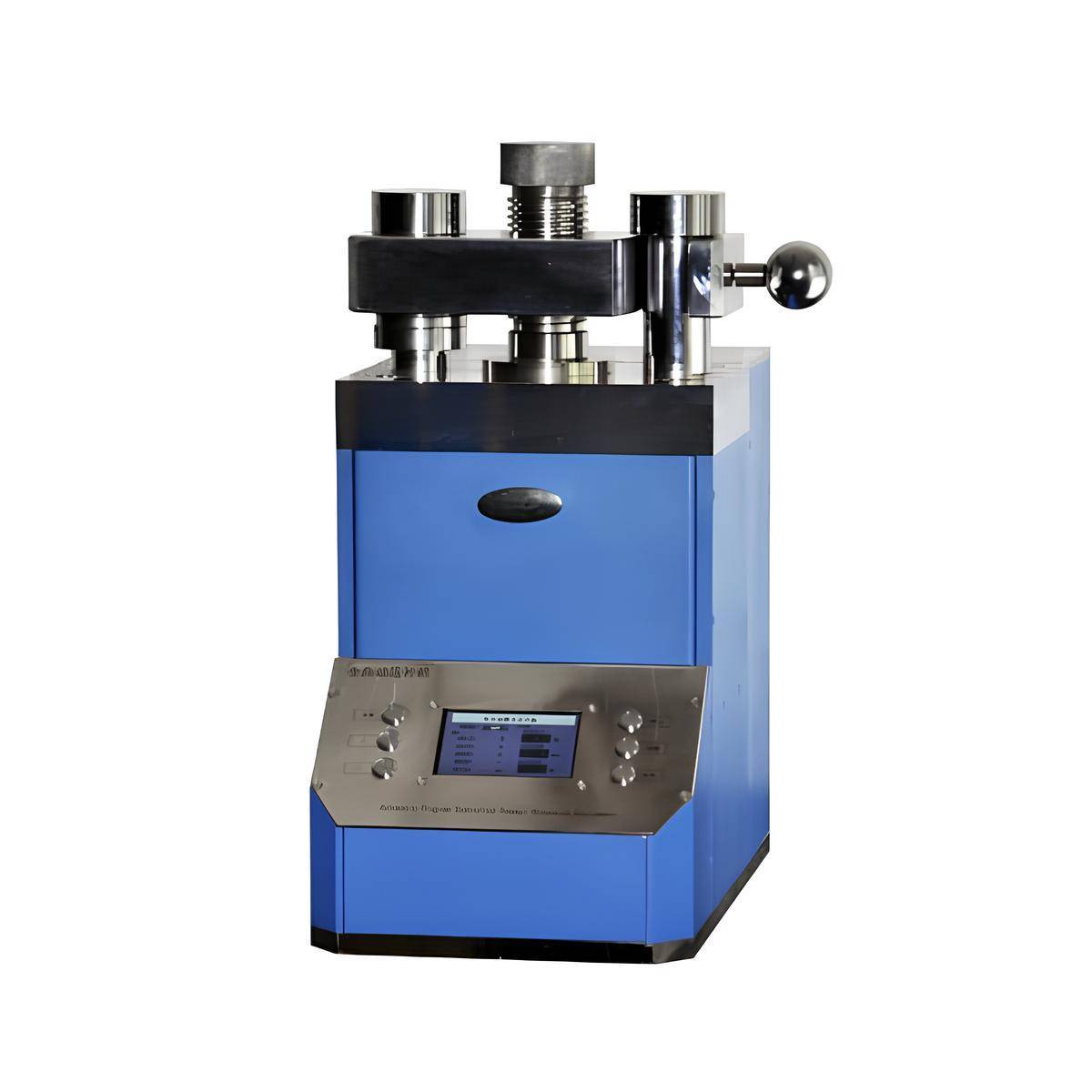

The pressed pellet technique is a popular method used in sample preparation for X-ray fluorescence (XRF) analysis. It involves compressing a finely ground sample into a pellet under high pressure. This technique is preferred over other sample preparation methods because it ensures homogeneity and reproducibility of the sample, leading to accurate and precise analysis results. The particle size of the sample used in this technique is a crucial factor that affects the quality of the pellet. Therefore, understanding the role of particle size in sample preparation is essential in achieving optimal analysis results.

Table of Contents

Benefits of the Pressed Pellet Technique

The pressed pellet technique has become increasingly popular in laboratory settings due to its many benefits. This technique offers several advantages over other methods of sample preparation, making it a preferred choice for many laboratory professionals. Below are some of the key benefits of the pressed pellet technique.

Improved Homogenization

One of the most significant benefits of the pressed pellet technique is that it allows for better homogenization of samples. When using this technique, the sample is ground to a particle size of <50µm, which allows for better mixing of the sample with the binding agent. As a result, the sample is more evenly distributed, and the data obtained from analysis is more consistent.

Increased Sensitivity

Smaller particle sizes have a larger surface area, which can improve the accuracy and sensitivity of certain types of analyses. This is particularly important when analyzing trace elements, where even small variations in the sample can have a significant impact on the results.

Reduced Errors

The use of smaller particle sizes can also reduce the occurrence of errors caused by variations in bulk composition. This is because smaller particles allow for better mixing, resulting in a more representative sample.

Easy to Use

The pressed pellet technique is relatively easy to use and requires minimal equipment. All that is needed is a die and a hydraulic press, making it a cost-effective option for many laboratories.

Increased Efficiency

By optimizing particle size and using the pressed pellet technique, laboratory professionals can improve the quality of their analyses and increase the efficiency of their work. This is because the technique allows for more consistent results, reducing the need for repeat analyses and saving time and resources.

In summary, the pressed pellet technique offers several benefits over other methods of sample preparation, including improved homogenization, increased sensitivity, reduced errors, ease of use, and increased efficiency. By understanding the importance of particle size in this technique and optimizing the process accordingly, laboratory professionals can obtain reliable and accurate data, making it a preferred choice for many laboratory applications.

The Role of Particle Size in Sample Preparation

Particle size plays a critical role in the preparation of samples for analysis using the pressed pellet technique. The homogeneity and reproducibility of the resulting pellets are highly dependent on the particle size. It is essential to use particles with a uniform size distribution for achieving consistent results.

Impact of Particle Size on Homogeneity

When particles of different sizes are mixed together during sample preparation, the smaller particles tend to fill the gaps between the larger ones, resulting in a less homogeneous mixture. This can lead to uneven distribution of the sample in the pellet, affecting the accuracy of the analysis. Therefore, the use of particles with a uniform size distribution is essential in achieving consistent and accurate results.

Impact of Particle Size on Packing Density

In addition to the homogeneity of the mixture, the particle size can also affect the packing density of the sample, which in turn affects the mechanical stability of the pellet. Smaller particles can result in a denser packing and a more mechanically stable pellet, while larger particles may lead to a less dense packing and a weaker pellet. Therefore, careful consideration of the particle size during sample preparation is critical in ensuring the accuracy and reliability of analytical results.

Particle Size and XRF Analysis

In XRF analysis, the level of accuracy and reliability of the results is highly dependent on the sample preparation technique used. The use of pressed pellets is a standard method of preparing samples for XRF analysis. During the process of making pressed pellets, the sample is ground to a fine particle size, mixed with a binder or grinding aid, and pressed under high pressure to form a pellet. The particle size should be reduced as much as possible before the pelletizing process to ensure a uniform mixture and accurate results. A particle diameter of 40 µm or lower is commonly considered acceptable.

Importance of Careful Sample Preparation

To achieve optimal sample preparation and accurate analysis in a laboratory setting, careful consideration of the particle size is critical. The particle size affects the homogeneity of the mixture, packing density, and mechanical stability of the pellet. It is essential to use particles with a uniform size distribution and reduce the particle size as much as possible before the pelletizing process to ensure consistent and accurate results. By paying close attention to the particle size during sample preparation, laboratory professionals can achieve optimal sample preparation and obtain reliable analytical results.

Choosing the Right Pressure for Pressing Pellets

The pressed pellet technique is a popular analytical method used to analyze solid samples in laboratories. In this technique, the sample is compressed under high pressure to form a pellet, which is then analyzed using analytical techniques. The particle size of the sample plays a critical role in the pressed pellet technique as it determines the pressure required to form a pellet of the desired quality.

Importance of Particle Size

If the particle size is too large, the pellet may not be formed, or it may have a non-uniform structure. On the other hand, if the particle size is too small, the pellet may be too dense, and it may not be possible to obtain accurate analytical results. Therefore, it is essential to choose the right pressure for pressing pellets based on the particle size of the sample.

Pressure and Particle Size

In general, smaller particles require higher pressures to form a pellet, while larger particles require lower pressures. It is also important to note that the pressure should be increased gradually to avoid damage to the sample.

Trade-Off Between Pellet Size and Compaction Pressure

When using pellet dies for the pressing of powders, there is a trade-off between the size of the required pellet and the compaction pressure that can be achieved. Pellet dies usually have a maximum rated load that limits the pressure to under 1000 MPa, but it can still be noted that a pressure of, say, 250 MPa can be achieved with as little as 0.5 tonnes in a pellet die of 5 mm. To achieve the same pressure in a 40 mm die, we need over 30 tonnes of load.

Evaluating the Lab Press

Choosing the right lab press for your application typically involves an evaluation of several issues, including the load or force required to put on the sample, the room needed inside of the sample compartment of the press, the daylight opening and the size of the platens, the strength or energy (work) required to pump the press up to the required load, and whether the rate of ramp up to the desired clamp force or ramp down from load must be controlled. Other factors to consider include the space available in your lab, whether you need to move the press, the cost of the features you require, and the cost of optional features.

Hydraulic Press vs. Hand Press

If you are doing briquetting for XRF, a hydraulic press is necessary. However, if you are doing KBr pellets, you should first consider a hand press. Hand presses make excellent transparent KBr pellets with minimal work. They require virtually no lab space and they are portable. Furthermore, they are relatively easy to operate. The major drawbacks of hand-operated presses are that they do not lend themselves well to creating samples that can be stored for future reference and they are either not evacuable or cannot be evacuated with the efficiency of a die set designed for a hydraulic press.

In conclusion, by choosing the right pressure for pressing pellets, laboratory professionals can obtain reliable and accurate analytical results, which are essential for research and development in various fields, including pharmaceuticals, materials science, and environmental analysis.

The Impact of Pellet Thickness on Analysis Results

The pressed pellet technique is a widely used method for preparing solid samples for analysis in a laboratory. The thickness of the pellet plays an important role in the analysis, as it can affect the sensitivity and accuracy of results.

Importance of Pellet Thickness

A thicker pellet may result in reduced sensitivity due to the attenuation of the signal, while a thinner pellet may not provide enough sample for accurate measurement. Therefore, it is crucial to carefully control the thickness of the pellet to obtain accurate and precise analysis results.

Escape Depth of Elements

The thickness of the pellet is important to achieve the best analytical results. The pellet must be infinitely thick to the X-ray beam for all the elements that are being measured. X-rays produced in the sample must be able to escape the sample without being reabsorbed in order to make it to the detector to be measured. The escape depth of a particular element is an element-dependent issue. Therefore, a particular pressed pellet may provide good results for some elements but not for others.

Calculation of Absorption Capability

The absorption capability of a sample can be calculated from its average elemental composition and the mass absorption coefficient for each element present. The sample's ability to reabsorb X-rays is directly proportional to the sample's average atomic mass.

Optimal Pellet Thickness

Usually, a pellet made with 8-10g of sample for a 32mm diameter pellet or 13-15g of sample for 40mm diameter pellet will be sufficiently thick for the elements that can be measured by even the most powerful WDXRF instruments currently available. It is important to make sure that the pressed pellet is thicker than the escape depth of the highest energy element you want to measure.

Impact of Contamination

Contamination is an additional consideration in the preparation of high-quality pressed pellets for XRF analysis. Contamination usually occurs during the sample grinding process and originates from two main sources: the sample preparation device and sample to sample cross-contamination. Larger particle sizes can result from the presence of hard-to-grind phases in a sample resulting in variable grinding of the sample. The presence of larger particle sizes at the analysis surface of the sample can lead to analysis errors through the "shadow effect" where larger grains shadow the X-ray signal coming from the smaller grains at the surface of the pellet.

Conclusion

In conclusion, the thickness of the pellet is a critical factor in the pressed pellet technique, as it can impact the quality of the analysis results. Therefore, it is crucial to carefully control the thickness of the pellet to obtain accurate and precise analysis results. By understanding the importance of pellet thickness in the pressed pellet technique, we can ensure the reliability and accuracy of laboratory analysis.

Conclusion

In conclusion, the pressed pellet technique is an effective way to prepare samples for analysis. The particle size of the sample plays a crucial role in the success of the technique, and it is important to choose the right pressure and pellet thickness for optimal results. By using the pressed pellet technique, researchers can achieve accurate and precise results in their analysis of various materials. This technique is widely used in many fields, including pharmaceuticals, environmental science, and materials science. Overall, the pressed pellet technique is a valuable tool for sample preparation and analysis.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

Related Articles

- Understanding Cold Isostatic Pressing: Process, Comparisons, and Applications

- Effective Preparation of Samples for XRF Analysis via Pressed Pellets Method

- Understanding the Technical Aspects of Cold Isostatic Pressing

- Understanding Cold Isostatic Pressing (CIP) and Its Advantages

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press