Introduction to Isostatic Pressing

Isostatic pressing is a process that involves uniformly applying pressure to a material from all directions. This process is used to produce a range of materials, including ceramics, metals, and polymers. The two most common types of isostatic pressing are hot isostatic pressing (HIP) and cold isostatic pressing (CIP). HIP is used to produce high-performance materials, such as those used in the aerospace and defense industries, while CIP is used to produce less dense materials. The isostatic pressing process offers several advantages, including increased density, improved mechanical properties, and reduced porosity.

Table of Contents

- Introduction to Isostatic Pressing

- Types of Isostatic Pressing: HIP and CIP

- Cold Isostatic Pressing Process

- Hot Isostatic Pressing Process

- Advantages and limitations of isostatic pressing

- Warm Isostatic Pressing Process

- Isostatic Pressing in Aerospace and Defense Industry

- Increase in Investment in HIP Technology

- Conclusion: The Importance of Isostatic Pressing

Types of Isostatic Pressing: HIP and CIP

Isostatic pressing is a popular technique used for manufacturing ceramics, metals, and various other materials. The method involves applying equal pressure in all directions to a material, resulting in a uniform and high-density product. There are two main types of isostatic pressing: Hot Isostatic Pressing (HIP) and Cold Isostatic Pressing (CIP).

Hot Isostatic Pressing (HIP)

HIP is a high-temperature process that involves heating the material in a pressurized chamber. The combination of heat and pressure results in a uniform and dense material. HIP is commonly used in the aerospace and medical industries, as well as for the densification of WC cutting tools and PM tool steels. It is also used to close internal porosity and improve properties in superalloy and Ti alloy castings for the aerospace industry.

Cold Isostatic Pressing (CIP)

CIP, on the other hand, is a low-temperature process that involves placing the material in a flexible container and subjecting it to high-pressure water or gas. This process also results in a uniform and dense material but is typically used for smaller and more intricate parts. CIP is used in the production of small parts, such as turbine blades and dental implants.

Both HIP and CIP offer unique advantages and disadvantages, and the choice between the two types of isostatic pressing is dependent on the specific needs of the application.

Advantages of Isostatic Pressing

The main advantage of isostatic pressing is the absence of wall friction as pressure is being applied from all directions. It produces compacts of practically uniform grain structure and density, irrespective of shape. Isostatic pressing can be used to eliminate residual porosity from a sintered PM part.

Conclusion

In conclusion, isostatic pressing has revolutionized the production of high-quality, uniform materials and continues to be a valuable tool in the manufacturing industry. HIP is commonly used in the aerospace and medical industries, while CIP is used in the production of small parts. Both techniques offer unique advantages and disadvantages, and the choice between the two types of isostatic pressing is dependent on the specific needs of the application.

Cold Isostatic Pressing Process

Cold isostatic pressing (CIP) is a variation of isostatic pressing used to compact and shape materials at room temperature. The process involves placing the material inside a flexible container, which is then filled with a liquid medium, usually water.

Step 1: Material Placement

The first step in the cold isostatic pressing process is placing the material inside a flexible container made of rubber or elastomer. The material can be in the form of a dry or semi-dry powder.

Step 2: Container Filling

Once the material is placed in the container, it is filled with a liquid medium, usually water. The liquid serves as a medium for the application of pressure to the material.

Step 3: Compression

After filling the container with the liquid medium, it is subjected to high pressure, typically between 100 and 700 MPa. The pressure is applied uniformly in all directions, which causes the material to be compressed and shaped uniformly.

Step 4: Green Body Formation

As a result of the compression, the powder particles mechanically bond to each other, creating a solid green body. The green body has a uniform density, even for large height/diameter ratio parts, which is impossible to achieve by uniaxial pressing.

Step 5: Liquid Removal

Finally, the liquid is removed, and the container expands to its original form, allowing the green body to be retrieved. The green body is then sintered to achieve full density.

CIP is commonly used to produce ceramics, metals, and composite materials with high density and uniformity. The process is useful for producing materials with high strength and toughness, and for creating parts with precise dimensions and tolerances.

However, the process is not without its drawbacks, as it can be time-consuming and expensive. CIP also requires specialized equipment and expertise to ensure that the process is carried out correctly.

In conclusion, the cold isostatic pressing process involves placing a material inside a flexible container, filling it with a liquid medium, subjecting it to high pressure, and removing the liquid to create a solid green body. The process is useful for producing high-quality materials with precise dimensions and tolerances, but it requires specialized equipment and expertise.

Hot Isostatic Pressing Process

Hot isostatic pressing (HIP) is a manufacturing process that is used to compress materials under high temperature and pressure. This process is commonly used in the aerospace and medical industries to produce high-performance components that require exceptional strength and durability.

Stage 1: Loading the Material

The first step in the HIP process is to load the material into a high-pressure vessel. The material is placed inside the vessel, which is then sealed to prevent air from entering.

Stage 2: Heating the Material

The vessel is then heated to a temperature that is typically between 900 and 1200 degrees Celsius. The heat is necessary to soften the material and make it more malleable.

Stage 3: Applying Pressure

Once the material has been heated to the desired temperature, pressure is gradually applied to the vessel. The pressure can be as high as 200 MPa, which is sufficient to compress the material and eliminate any voids or defects.

Stage 4: Cooling the Material

After the material has been compressed, the vessel is slowly cooled to room temperature. This process is necessary to ensure that the material retains its shape and properties.

Stage 5: Post-Treatment

The final step in the HIP process is post-treatment. This can involve various treatments, such as heat treatment, polishing, or coating, depending on the requirements of the final product.

Advantages of Hot Isostatic Pressing

The HIP process offers various advantages over traditional manufacturing techniques. One of the key advantages is that it can be used to produce components from difficult-to-process materials, such as ceramics, composites, and superalloys. Additionally, the resulting material has improved mechanical properties, including increased strength, toughness, and ductility.

Applications of Hot Isostatic Pressing

The HIP process is widely used in various end-user industries, such as manufacturing, automotive, electronics and semiconductor, medical, aerospace and defense, energy and power, research and development, and others. In the aerospace industry, it is used for manufacturing aerospace castings, jet aircraft engine components, and turbine blades. In the medical industry, it is used for producing implants, surgical instruments, and other medical devices.

In summary, hot isostatic pressing is a powerful manufacturing technique that enables the production of high-performance components with exceptional properties and reliability. The HIP process offers various advantages over traditional manufacturing techniques and is widely used in various industries to produce complex components from difficult-to-process materials.

Advantages and limitations of isostatic pressing

Advantages of isostatic pressing

Isostatic pressing is a manufacturing process that applies uniform pressure from all directions to produce complex ceramic, metal, and composite parts with high precision. This method offers several advantages over other methods of powder compaction, including:

Uniform density and low porosity

Isostatic pressing allows for the production of parts with uniform density and low porosity, ensuring high strength and reliability. This also reduces the need for subsequent machining.

Production of complex geometries

Isostatic pressing is capable of producing parts with complex geometries and tight tolerances that may be difficult or impossible to achieve through other methods. It is suitable for the production of parts with internal shapes, including threads, splines, serrations, and tapers.

Efficient material utilization

Isostatic pressing is highly efficient in terms of material utilization, especially for difficult-to-compact and expensive materials such as superalloys, titanium, tool steels, stainless steel, and beryllium.

Limitations of isostatic pressing

Isostatic pressing also has some limitations that should be taken into consideration before using it:

High tooling and equipment costs

Isostatic pressing requires specialized tooling and equipment, which may be expensive to acquire and maintain.

Limited scalability

Isostatic pressing is typically used for low-volume production of specialty parts, making it less suitable for high-volume production.

Long cycle times

Isostatic pressing involves long cycle times, which can result in a slower production rate and higher costs.

Unsuitable for certain materials

Isostatic pressing may not be suitable for certain materials, such as those that are brittle or prone to cracking under pressure.

Lower accuracy of pressed surfaces

Compared to other methods such as mechanical pressing or extrusion, isostatic pressing may result in lower accuracy of pressed surfaces adjacent to the flexible bag, usually necessitating subsequent machining.

Despite these limitations, isostatic pressing remains a popular and effective method for producing high-quality parts in a variety of industries, including aerospace, defense, medical, and energy. Understanding the advantages and limitations of isostatic pressing is essential for manufacturers and engineers looking to optimize their production processes and achieve the best possible results.

Warm Isostatic Pressing Process

Isostatic pressing is a process of compacting powders into uniform shapes ideal for use in various applications. Warm isostatic pressing (WIP), a specific type of isostatic pressing, involves the use of elevated temperatures to improve the densification process.

The Process of Warm Isostatic Pressing

In WIP, a powder is placed in a flexible container, and high pressure is applied from all directions, causing the powder to be compressed into a dense shape. The temperature is then raised to a level where the material becomes soft and malleable, allowing it to be further compressed and densified. The result is a highly uniform product with excellent mechanical properties and resistance to cracking or other types of damage.

Applications of Warm Isostatic Pressing

WIP is widely used in the production of advanced ceramics, such as those used in high-temperature applications like jet engines and nuclear reactors. It is also used in the production of metal parts, such as those used in aerospace and defense applications. Overall, WIP is an important tool for producing high-quality materials with precise shapes and properties, and its versatility makes it a valuable technology for a wide range of industries.

Types of Warm Isostatic Pressing Structures

There are three types of structures suitable for warm isostatic pressing equipment:

- Bolt Structure

- Moment Tooth Structure

- Steel Wire Winding Structure

The bolt structure is suitable for small and medium-sized isostatic pressing equipment, generating no noise and not causing oil or water pollution on the site. The moment tooth structure is suitable for medium and large isostatic pressing equipment, sharing the same characteristics as the bolt structure. The steel wire winding structure is suitable for large-scale WIP equipment, producing low noise and not causing oil or water pollution on the site.

Operating Temperature of Warm Isostatic Pressing

The operating temperature of WIP includes the working temperature and the ambient temperature. The working temperature can be set within the range of 0-240°C, while the ambient temperature can be used normally at 10-35°C. The working static pressure is 0-240MPa (set within range).

The selection of the operating temperature of WIP mainly depends on the characteristics of the powder material and the requirements of the molding effect. The operating temperature should be reasonably determined according to the specific situation to ensure the molding quality and efficiency.

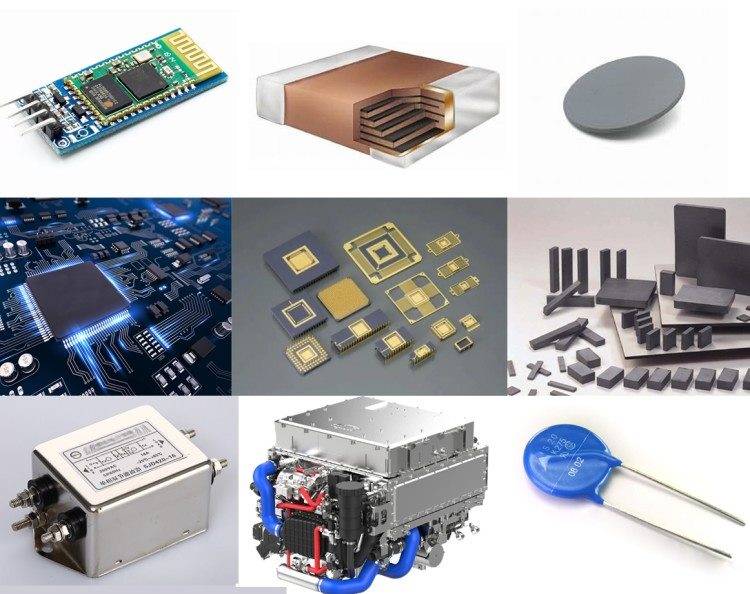

Warm Isostatic Laminator

Warm Isostatic Laminator is best suited for compressing Green sheets to produce high-quality monolithic multilayer ceramic electronic components (such as MLCC, MLCI, LTCC, HTCC, MCM, Piezoelectric, Filter, Varistor, Thermistor, etc.). Delivering compressed bodies of higher quality than those manufactured by the conventional uniaxial press method, Warm Isostatic Laminators are widely used as de facto standard systems.

In conclusion, WIP is a cutting-edge technology that enables the isostatic pressing of powders at a temperature that does not exceed the boiling point of the liquid medium. It has revolutionized the manufacturing industry and has enabled the production of complex parts and components with precision and efficiency.

Isostatic Pressing in Aerospace and Defense Industry

Isostatic pressing is a manufacturing technique that can produce dense and uniform products with complex shapes and high precision, making it a suitable choice for creating mission-critical components in the aerospace and defense industry. The process involves subjecting materials to high-pressure conditions, which eliminates internal defects caused by uneven cooling rates and creates high-performance materials with superior strength, stiffness, and durability.

Benefits of Isostatic Pressing in Aerospace and Defense Industry

The aerospace and defense industry requires high-performance materials for mission-critical components. Isostatic pressing is a cost-effective and efficient production method that can produce high-quality parts with minimal waste and material consumption, making it an ideal choice for aerospace and defense manufacturers looking to optimize their production processes. Additionally, isostatic pressing can produce parts with complex shapes and high precision, which is essential for creating turbine blades, rocket nozzles, and other intricate components.

Applications of Isostatic Pressing in Aerospace and Defense Industry

Isostatic pressing has extensive applications in the aerospace and defense industry, where high-performance materials are crucial for mission-critical components. The process can be used to fabricate composite materials, which offer high strength, stiffness, and durability. Isostatic pressing can also be used to produce parts with complex shapes and high precision, making it suitable for creating turbine blades, rocket nozzles, and other intricate components.

Isostatic Pressing vs. Other Manufacturing Techniques in Aerospace and Defense Industry

Compared to other manufacturing techniques such as uniaxial pressing, isostatic pressing applies a uniform, equal force over the entire product, regardless of shape or size. The food products are compressed by uniform pressure from every direction and then returned to their original shape when the pressure is released. This ensures uniform strength in all directions, uniform density, and shape flexibility. Die-wall friction, which exerts a major influence on the density distribution of cold-pressed parts, is absent, so much more uniform densities are obtained. The elimination of die-wall lubricants also permits higher pressed densities and eliminates problems associated with lubricant removal prior to or during final sintering.

Conclusion

Isostatic pressing is likely to play an increasingly important role in the aerospace and defense industry in the years to come. With its ability to produce high-performance materials, isostatic pressing has become a popular choice for manufacturers looking to optimize their production processes. From composite materials to intricate components, the applications of isostatic pressing in the aerospace and defense industry are extensive.

Increase in Investment in HIP Technology

Hot Isostatic Pressing (HIP) technology has gained increased investment over the years due to its ability to produce parts that are stronger and more reliable than those made using traditional manufacturing methods. HIP technology is widely adopted in the aerospace, automotive and medical industries, among others. The following are some of the reasons for the increase in investment in HIP technology:

Improved Material Properties

HIP technology is used to manufacture components such as turbine blades, engine parts, and medical implants. The technology involves applying high pressure from all directions to a material to achieve a uniform density and eliminate any defects, which results in improved mechanical properties of the parts such as investment castings. The processed parts exhibit enhanced reliability and extension of service life, allowing for smaller, lighter-weight parts with similar or superior performance.

Cost Reduction

When incorporated as an integral part of the manufacturing process, HIP reduces scrap and improves yield, allowing the replacement of wrought components by castings. Also, it reduces quality assurance inspection requirements, often covering the savings on radiographic costs. Optimized material properties parameters can be established to minimize subsequent heat treatment requirements, thus reducing the total production costs of a product.

Diversified Applications

HIP technology has been widely adopted in various industries such as aerospace, automotive, and medical. It is used to manufacture a wide range of components, including large and massive near net shape metal components such as oil and gas parts weighing up to 30 tonnes or net shape impellers up to one meter in diameter. Additionally, it can be used to make small PM HSS cutting tools, such as taps or drills made from PM HIP semi-finished products, which can weigh less than 100 grams or even very tiny parts such as dental brackets.

Improved Powder Properties

HIP is also used in the production of additive manufacturing powders to improve their properties. Encapsulated powders can be consolidated to create fully dense materials, and similar and dissimilar materials can be bonded together to manufacture unique, cost-effective components.

Conclusion

The increasing demand for high-performance materials and the need for more efficient manufacturing processes have contributed to the growth of HIP technology. However, the high cost of HIP equipment and the need for specialized expertise in the process could pose a challenge to its widespread adoption. Nonetheless, as new applications are discovered and the benefits of HIP technology become clearer, it is expected that more companies will invest in this technology to improve the quality and performance of their products.

Conclusion: The Importance of Isostatic Pressing

Isostatic pressing is a highly effective technique for manufacturing high-quality parts and components. The process is widely used in various industries, including aerospace, defense, and biomedical. One of the main advantages of isostatic pressing is that it can produce parts that are free from defects, porosity, and other imperfections. This makes it ideal for creating parts that require high strength, durability, and reliability. Moreover, isostatic pressing can be used to create parts with complex shapes and sizes, which are difficult to produce using other techniques. With the increase in investment in HIP technology, isostatic pressing is expected to become even more important in the future.

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

Related Articles

- Understanding Cold Isostatic Pressing and Its Applications

- Electric Lab Cold Isostatic Press (CIP): Applications, Benefits, and Customization

- Comprehensive Guide to Isostatic Pressing Molds: Types, Processes, and Applications

- Cold Isostatic Pressing (CIP): A Proven Process for High-Performance Parts Manufacturing

- Understanding the Basics of Isostatic Pressing