Blog

Application of Hot Isostatic Pressing Technology in Special Ceramic Preparation

1 year agoExplores the use of HIP technology in special ceramics, focusing on preparation, characteristics, and industry trends.

Learn More

Research on Zirconia Ceramics in Dental Restoration

1 year agoExplores the properties, preparation, and advantages of zirconia ceramics in dental restoration.

Learn More

Defects and Solutions for Isostatically Pressed Ceramic Balls

1 year agoThis article discusses various defects in isostatically pressed ceramic balls and provides solution strategies for each type of defect.

Learn More

Zirconia Ceramic Sintering Processes and Common Issues

1 year agoAn in-depth look at various sintering methods for zirconia ceramics and common problems encountered during the process.

Learn More

Isostatic Pressing Technology: Principles, Classification, and Applications

1 year agoAn in-depth look at isostatic pressing technology, its types, and diverse applications across various industries.

Learn More

Comprehensive Overview of Zirconia Ceramic Materials

1 year agoA detailed exploration of zirconia ceramics, including properties, history, preparation, molding, sintering, and applications.

Learn More

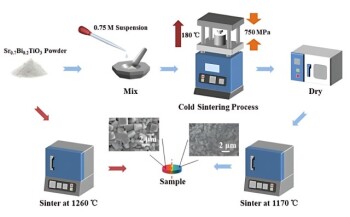

Nine Precision Molding Processes of Zirconia Ceramics

1 year agoAn overview of nine advanced molding processes for zirconia ceramics, including dry and wet methods.

Learn More

Advanced Alumina Ceramics: Applications and Manufacturing Techniques

1 year agoOverview of alumina ceramics' applications and manufacturing methods, including molds, isostatic pressing, and green body formation.

Learn More

Advanced Alumina Ceramics: Applications and Manufacturing Techniques

1 year agoThis article discusses the applications and manufacturing techniques of advanced alumina ceramics, including molds, isostatic pressing, and green bodies.

Learn More

Zirconia Ceramic Rod Production Processes: Isostatic Pressing vs. Dry Pressing

1 year agoA comparison of isostatic pressing and dry pressing in zirconia ceramic rod production, highlighting differences and advantages.

Learn More

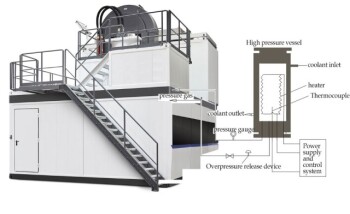

Choosing the Right Warm Isostatic Press: Key Factors to Consider

1 year agoGuidelines for selecting a suitable warm isostatic press based on cavity size, pressure range, accuracy, temperature, capacity, ease of use, maintenance, and environmental restrictions.

Learn More

Three Major Applications of Hot Isostatic Pressing Technology

1 year agoHot isostatic pressing technology ensures high-performance components through densification, diffusion bonding, and powder metallurgy near-net forming.

Learn More

Application of Hot Isostatic Pressing Technology in Nickel-Based Casting High-Temperature Alloys

1 year agoExplores the use of hot isostatic pressing to enhance the properties of nickel-based casting high-temperature alloys in aerospace applications.

Learn More

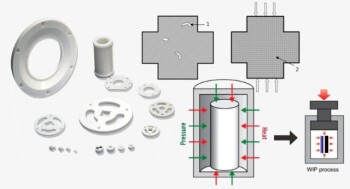

Ceramic Isostatic Pressing Mold Technology

1 year agoExploring the design and factors affecting ceramic isostatic pressing molds.

Learn More

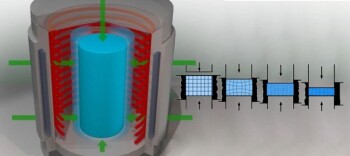

Hot Isostatic Pressing: A Versatile Technology for Advanced Material Processing

1 year agoExplores the origins, principles, and applications of hot isostatic pressing in various material fields.

Learn More

Isostatic Pressing Technology: Revolutionizing Ceramic Material Densification

1 year agoExplore how isostatic pressing techniques enhance ceramic properties, achieving 100% theoretical density and eliminating porosity.

Learn More

PVD Sputtering Targets and Hot Isostatic Pressing: Part 1

1 year agoExplores the use of hot isostatic pressing in producing high-quality sputtering targets and the applications of PVD sputtering technology.

Learn More

PVD Sputtering Targets and Hot Isostatic Pressing: Part 2

1 year agoThis article discusses the manufacturing and optimization of PVD sputtering targets, focusing on techniques like hot isostatic pressing and high pressure heat treatment.

Learn More

Selecting Isostatic Pressing Equipment for High-Density Molding

1 year agoAn in-depth look at isostatic pressing techniques and equipment selection for achieving high-density molding.

Learn More

Hot Isostatic Pressing Technology: Principles and Applications

1 year agoAn in-depth look at the development, working principle, and diverse applications of hot isostatic pressing technology across various industries.

Learn More

Application of Isostatic Graphite in the Photovoltaic Industry

1 year agoAn overview of the use of isostatic graphite in various stages of photovoltaic production and its market demand.

Learn More

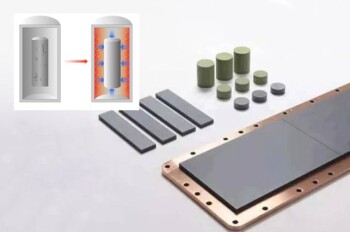

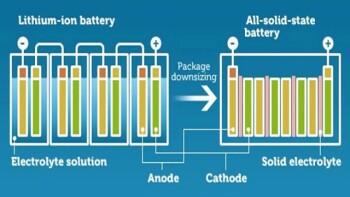

Isostatic Pressing Technology for Solid-State Batteries

1 year agoFocus on isostatic pressing to commercialize next-gen batteries.

Learn More

Isostatic Pressing Technology in Solid-State Battery Production

1 year agoExploring the role of isostatic pressing technology in manufacturing solid electrolytes for next-generation solid-state batteries.

Learn More

Essential Equipment for Mass Production of Solid-State Batteries: Isostatic Press

1 year agoDiscusses the role of isostatic pressing technology in enhancing solid-state battery performance and production efficiency.

Learn More

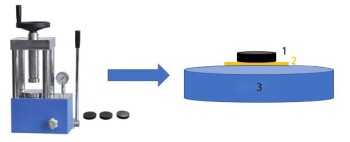

Sample Preparation Techniques for Infrared Spectroscopy Analysis

1 year agoComprehensive guide on selecting and applying sample preparation methods for infrared spectroscopy.

Learn More

XPS Powder Sample Preparation and Precautions

1 year agoGuidelines for preparing and handling powder samples for XPS analysis.

Learn More

Overview of Basic Laboratory Pumps

1 year agoAn overview of various types of laboratory pumps including constant flow, oil-free vacuum, rotary vane, diaphragm, chemical hybrid, molecular, injection, and circulating water pumps.

Learn More

Basic Laboratory Test Chamber Equipment

1 year agoOverview of essential lab test chambers for various environmental simulations.

Learn More

Basic Constant Temperature Heating Equipment in Laboratories

1 year agoOverview of various constant temperature heating devices used in laboratories.

Learn More

Basic Laboratory Culture Equipment

1 year agoOverview of essential laboratory equipment for biological and microbiological research.

Learn More