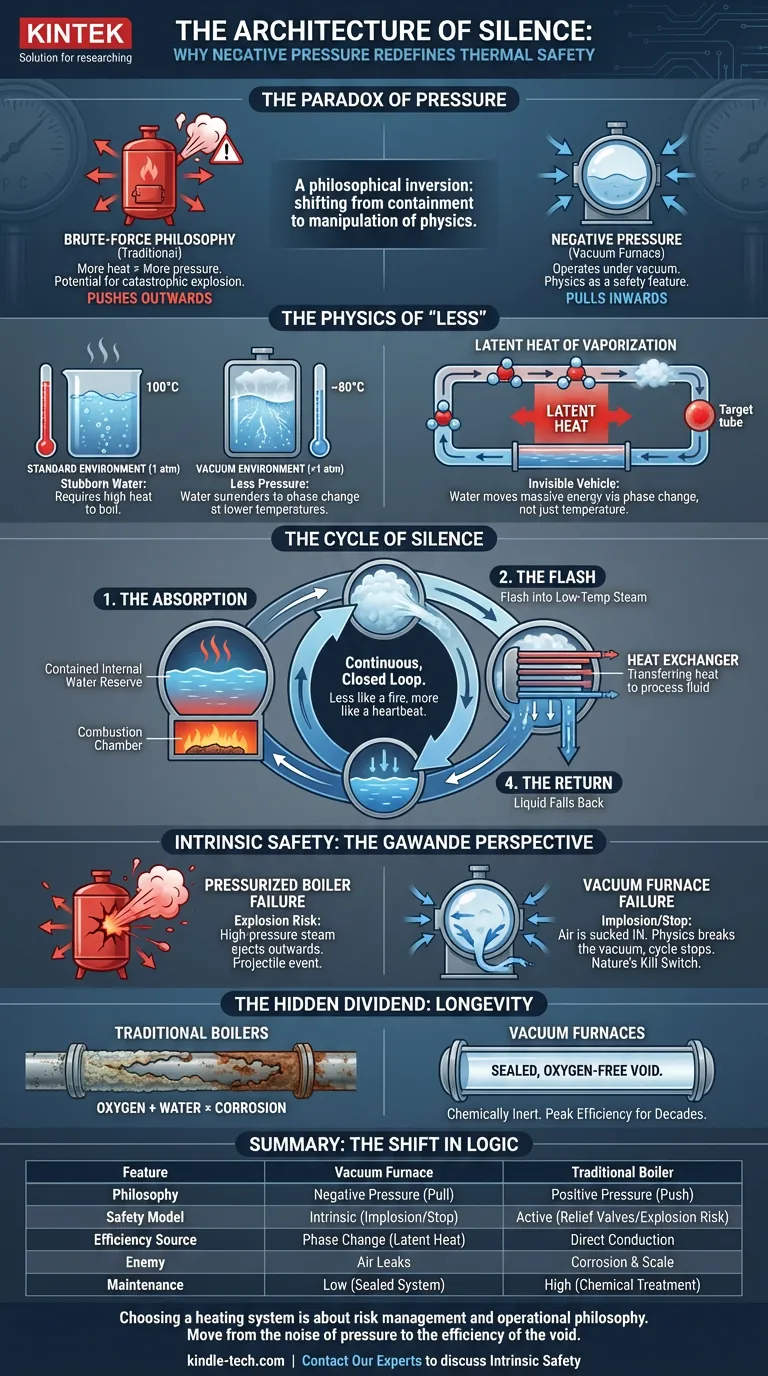

The Paradox of Pressure

In the history of thermal engineering, we have usually solved problems with force.

If we needed more heat, we added more pressure. If we needed to move energy faster, we built thicker walls to contain the potential explosion. The traditional boiler is a testament to this brute-force philosophy. It is effective, but it carries a silent, ever-present threat: the energy wants to get out.

The vacuum furnace represents a philosophical inversion.

Instead of pushing outwards, it pulls inwards. It is a system designed not around the strength of its walls, but around the manipulation of physics. By operating under negative pressure, it turns the laws of thermodynamics into a safety feature rather than a risk factor.

It is safer not because it has better sensors or thicker steel, but because the physics of the system makes a catastrophic explosion impossible.

The Physics of "Less"

To understand the genius of a vacuum furnace, you have to ignore the mechanics for a moment and look at the water.

In a standard environment, water is stubborn. It requires 100°C (212°F) to boil. To get steam that carries significant energy, you usually have to push past this boundary, pressurizing the vessel to superheat the steam.

The vacuum furnace changes the environment rather than the water.

By evacuating the air from the sealed chamber, the internal pressure drops. In this vacuum, water loses its stubbornness. It surrenders to a phase change at much lower temperatures—often around 80°C.

This is the "aha" moment: You are creating steam without the violence of high heat.

The Invisible Vehicle: Latent Heat

The water inside a vacuum furnace is not the product you are heating. It is a vehicle.

This is a critical distinction. The furnace contains a small, fixed amount of highly pure, deaerated water. It never leaves the system. It never touches your process fluid. Its only job is to pick up energy and move it.

It does this through Latent Heat of Vaporization.

When water turns to steam, it swallows a massive amount of energy to make that phase jump. It holds that energy "locked" inside the vapor. When it touches the heat exchanger, it condenses back to liquid, instantly releasing that massive packet of energy into your target system.

It is one of the most efficient transport mechanisms in nature.

The Cycle of Silence

The operation of a vacuum furnace is a continuous, closed loop. It is less like a fire and more like a heartbeat.

1. The Absorption

At the bottom of the vessel, a combustion chamber burns fuel. This heat is transferred not to the air, but to the internal water reserve.

2. The Flash

Because of the vacuum, the water doesn't slowly boil; it flashes into low-temperature steam. It expands rapidly, filling the vacuum chamber.

3. The Exchange

This steam rises and hits the heat exchanger—a bundle of tubes carrying the fluid you actually want to heat. The steam condenses instantly upon contact.

4. The Return

The water, now a liquid again, falls back to the bottom to be reheated.

Intrinsic Safety: The Gawande Perspective

In complex systems, as Atul Gawande often notes, we usually rely on checklists and vigilance to prevent disaster. In a pressurized boiler, safety relies on valves opening and sensors tripping.

A vacuum furnace relies on Intrinsic Safety.

If a pressurized boiler springs a leak, high-pressure steam explodes outward. It is a projectile event.

If a vacuum furnace springs a leak, air is sucked in.

The vacuum is broken. The pressure rises. The water stops boiling because it can no longer boil at low temperatures. The cycle simply stops. The physics that drives the system also acts as its kill switch. You don't need a sensor to tell the water to stop boiling; nature does it for you.

The Hidden Dividend: Longevity

There is a secondary psychological benefit to this system: the absence of decay.

Corrosion is the cancer of heating systems. It requires two things: water and oxygen.

- Traditional Boilers: Constantly fighting oxygen intake and mineral scale.

- Vacuum Furnaces: Operate in a sealed, oxygen-free void.

Without oxygen, rust cannot form. Without fresh water intake, mineral scale cannot build up. The environment inside the furnace is chemically inert. This means the equipment doesn't just last longer; it maintains its peak efficiency for decades rather than years.

The Trade-off: Integrity is Everything

No system is perfect. The vacuum furnace trades the risk of explosion for the requirement of integrity.

The seal is the system. If you lose the vacuum, you lose the heater. The vacuum pump is not an accessory; it is the heart monitor of the unit. For engineers used to brute-force heating, this requires a shift in maintenance mindset—focusing on tightness and seals rather than pressure checks and relief valves.

Summary: The Shift in Logic

| Feature | Vacuum Furnace | Traditional Boiler |

|---|---|---|

| Philosophy | Negative Pressure (Pull) | Positive Pressure (Push) |

| Safety Model | Intrinsic (Implosion/Stop) | Active (Relief Valves/Explosion Risk) |

| Efficiency Source | Phase Change (Latent Heat) | Direct Conduction |

| Enemy | Air Leaks | Corrosion & Scale |

| Maintenance | Low (Sealed System) | High (Chemical Treatment required) |

Conclusion

Choosing a heating system is rarely just about BTUs. It is about risk management and operational philosophy.

If your goal is to simply heat a substance, any boiler will do. But if your goal is to design out risk, eliminate the chemistry of corrosion, and utilize the elegance of phase-change physics, the vacuum furnace is the superior answer. It is a move away from the noise and danger of pressure, toward the efficiency of the void.

At KINTEK, we understand that the best laboratory equipment doesn't just work; it solves the invisible problems of safety and longevity before they ever arise. Contact Our Experts to discuss how our vacuum furnace solutions can bring this intrinsic safety to your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- Vacuum Induction Furnace Fault Inspection: Essential Procedures and Solutions

- Mastering Vacuum Furnace Brazing: Techniques, Applications, and Advantages

- Why Your Brazed Joints Are Inconsistent—And the Fix Isn't in the Furnace

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity