You know the feeling. A batch of meticulously prepared components emerges from the brazing furnace. But under inspection, the joints are weak, the filler hasn't flowed correctly, or worse, the base parts are distorted. Another expensive, time-consuming batch is destined for the scrap bin, and you're left wondering what went wrong.

Was the furnace too hot? Too cold? Did you hold it at temperature for too long? It’s a frustrating cycle of guesswork that many labs and production floors know all too well.

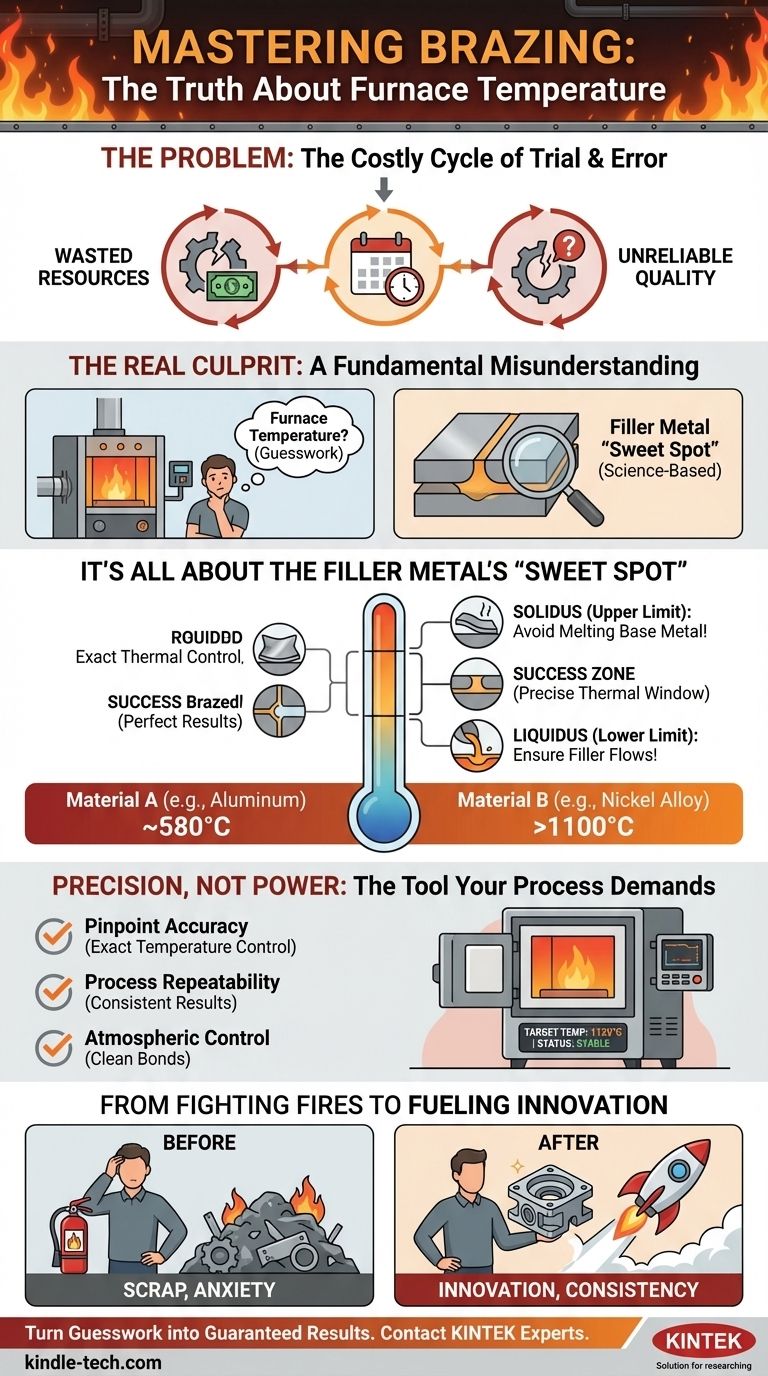

The Costly Cycle of Trial and Error

This isn't just a minor technical glitch; it's a significant business problem. When brazing fails, the consequences ripple outwards:

- Wasted Resources: Expensive materials and hours of skilled labor are lost with every failed batch.

- Project Delays: Troubleshooting pushes timelines back, delaying product development and delivery schedules.

- Unreliable Quality: Inconsistent joints create a risk of product failure in the field, damaging your company's reputation and potentially leading to costly recalls.

The common response is to tweak the furnace settings. "Let's add 20 degrees," or "Let's try holding it for five more minutes." Sometimes it seems to work, but the problem always returns. This is because these "solutions" are treating a symptom, not the underlying disease.

The Real Culprit: A Fundamental Misunderstanding of 'Temperature'

The core reason so many brazing operations struggle is a simple but profound misunderstanding. We ask, "What is the temperature of a brazing furnace?" when we should be asking, "What is the correct melting temperature for my specific filler metal?"

There is no single "correct" temperature for a brazing furnace. The furnace is merely the tool; the materials dictate the process.

It's All About the Filler Metal's "Sweet Spot"

Successful brazing happens in a precise thermal window, defined by two critical points:

-

The Lower Limit (Liquidus): The furnace must be hot enough to get the filler metal above its liquidus temperature—the point where it becomes fully molten and can flow into the joint via capillary action. If you're too cold, the filler remains slushy, creating voids and a weak bond.

-

The Upper Limit (Solidus): The temperature must remain safely below the solidus temperature of the base metals you are joining. If you get too hot, you risk melting, warping, or eroding the parts themselves.

Think of it like this: an aluminum alloy filler melts around 580°C, while a high-strength nickel alloy for aerospace needs over 1100°C. Using the same furnace setting for both would be a recipe for guaranteed failure. The "right" temperature is entirely dependent on the materials in your hands.

The reason the trial-and-error approach fails is that it ignores this fundamental principle. You're trying to find a magic number for the tool, instead of listening to what the materials require.

Precision, Not Power: The Tool Your Process Demands

To escape this cycle and achieve flawless, repeatable results, you don't need a furnace that gets hotter. You need a furnace that is smarter and more precise. You need a tool designed to master the material's specific thermal window.

This is precisely why KINTEK's laboratory and industrial furnaces are engineered for exacting thermal control. They are not just heating chambers; they are sophisticated thermal management systems built on a deep understanding of materials science.

- Pinpoint Accuracy: Our furnaces allow you to set and hold the specific temperature your filler metal demands, ensuring you operate perfectly within that critical liquidus-solidus window. No more guesswork.

- Process Repeatability: Whether you're brazing aluminum at 600°C or a nickel alloy at 1120°C, you can program the precise thermal profile and repeat it perfectly, batch after batch.

- Atmospheric Control: Many high-performance brazing operations require a vacuum or inert gas to prevent oxidation. Our furnaces provide this controlled environment, ensuring the filler metal can bond cleanly and effectively with the base materials.

KINTEK equipment isn't just a solution; it's the embodiment of the correct approach to brazing—one that puts material science first.

From Fighting Fires to Fueling Innovation

When you finally solve this persistent problem, you do more than just reduce scrap. You unlock new potential for your entire operation.

Instead of being limited to a few "safe" alloys you've managed to get working, you can confidently explore a wider range of materials to meet more demanding product specifications. Prototyping accelerates from weeks of uncertain tinkering to days of predictable execution. Your production line transforms from a source of anxiety into a model of consistency and reliability. You can take on more complex projects, manufacture higher-value components, and build a powerful reputation for quality.

Don't let the brazing temperature myth hold your projects back any longer. By understanding the core principles and using the right tools, you can turn one of your most frustrating challenges into a competitive advantage. If you're ready to move from guesswork to guaranteed results, our team is here to help you configure the perfect thermal solution for your unique materials and goals. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

Related Articles

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

- Vacuum Induction Furnace Fault Inspection: Essential Procedures and Solutions

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- Materials Science with the Lab Vacuum Furnace