Types of Sample Preparation

Smearing Type Preparation

To prepare a powder sample for X-ray photoelectron spectroscopy (XPS) using the smearing method, adhere double-sided conductive adhesive tape to the sample table. This tape serves as a conductive medium that ensures the sample is electrically connected to the measurement system.

Next, carefully spread the fine powder, ensuring the particle size is less than 0.2 mm, across the adhesive surface. The goal is to achieve an even distribution of the powder to ensure uniform data acquisition during the XPS analysis. The even distribution also helps in minimizing potential artifacts in the resulting XPS spectra.

After the powder is spread, use a one-way air inlet ear cleaning ball to gently clean the surface. This step is crucial for removing any loose particles or contaminants that could affect the accuracy of the XPS results. The one-way air inlet ensures that the cleaning process does not disturb the carefully spread powder, maintaining the integrity of the sample preparation.

This method is particularly effective for samples that are sensitive to mechanical pressure, as it avoids the need for pressing the powder into a tablet, which can sometimes alter the chemical or physical properties of the sample.

Tablet Preparation Method

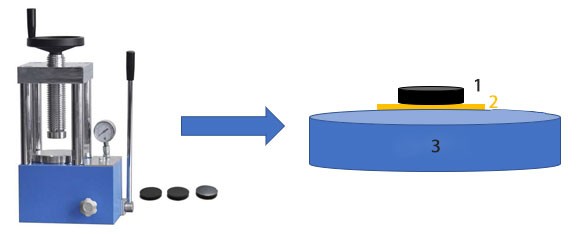

The process of preparing powder samples for XPS analysis using the tablet method involves several meticulous steps to ensure the integrity and cleanliness of the sample. Initially, the powder must be thoroughly dried and ground to a fine consistency. This step is crucial as it ensures uniformity and homogeneity in the final pressed tablet.

Next, the finely ground powder is compacted into a tablet shape. The dimensions of these tablets typically range between 5 to 10 millimeters in diameter and are less than 3 millimeters thick. This specific size is chosen to facilitate optimal handling and analysis during the XPS process.

Once the tablet is formed, it is adhered to a piece of conductive glue. This adhesive not only secures the tablet in place but also ensures that the sample remains electrically conductive, a critical requirement for XPS analysis. After adhering, the edges of the tablet are carefully trimmed to ensure a smooth and even surface.

Finally, the surface of the tablet is cleaned using a one-way air inlet ear cleaning bulb. This tool is specifically designed to remove any loose particles or debris, ensuring a pristine surface for analysis. This thorough cleaning process is essential to prevent any potential interference during the XPS testing phase.

By following these steps, the tablet preparation method ensures that the powder sample is ready for precise and accurate XPS analysis, thereby enhancing the reliability of the data collected.

Precautions for XPS Sample Handling

Pre-Testing Preparation

Before initiating the XPS analysis, it is crucial to ensure that the powder sample is thoroughly prepared to prevent any potential contamination. This process involves several key steps to maintain the integrity and purity of the sample.

First, the sample must be completely dried. This ensures that any moisture present does not interfere with the analysis and does not contribute to potential contamination. Drying can be achieved through various methods, such as using a desiccator or an oven set at a controlled temperature.

Next, the dried sample should be purged with nitrogen gas. This step is essential as it removes any residual oxygen and moisture from the sample environment, thereby minimizing the risk of oxidation and other chemical reactions that could alter the sample's composition. The nitrogen purge should be conducted in a controlled manner to ensure that the sample is not exposed to atmospheric conditions for an extended period.

Finally, the sample is subjected to vacuum at low temperature. This process helps to further eliminate any remaining gases and vapors, ensuring a clean and stable environment for the XPS analysis. The low temperature setting is particularly important as it helps to prevent any thermal degradation of the sample during the vacuuming process.

By following these meticulous pre-testing preparation steps, the accuracy and reliability of the XPS analysis can be significantly enhanced, providing more precise and meaningful results.

Handling Pressed Samples

When preparing pressed samples for XPS analysis, it is crucial to ensure that the pressed piece remains intact without any visible cracks. Cracks can lead to inconsistencies in the data collected during the analysis, potentially skewing results. To achieve this, the pressure applied during the pressing process must be carefully controlled, ensuring uniformity without over-compression.

Additionally, storing the samples separately is essential to prevent contamination. Contamination can arise from cross-contamination with other samples or from environmental factors such as dust or moisture. To mitigate this risk, samples should be stored in clean, airtight containers, and ideally, in a controlled environment where temperature and humidity can be regulated.

Here are some best practices for handling pressed samples:

- Pressure Control: Use a calibrated press to apply consistent pressure, avoiding both under-pressing and over-pressing.

- Storage Containers: Choose containers made of inert materials to prevent any chemical interactions with the sample.

- Environmental Control: Store samples in a cleanroom or a similarly controlled environment to minimize exposure to contaminants.

By following these guidelines, you can ensure that your pressed samples are of the highest quality, leading to more accurate and reliable XPS analysis results.

Element-Specific Considerations

When dealing with elements such as Carbon (C), Oxygen (O), Sodium (Na), Chlorine (Cl), Sulfur (S), Silicon (Si), and Calcium (Ca), special care must be taken to minimize their exposure to air. These elements are particularly susceptible to oxidation and other forms of atmospheric degradation, which can significantly alter their chemical states and affect the accuracy of XPS analysis.

To mitigate these risks, it is crucial to test these elements as soon as possible after preparation. This immediate testing helps to capture the true chemical state of the elements before they can react with ambient air. Additionally, the following precautions should be observed:

-

Reduced Air Exposure: Samples containing these elements should be handled in a controlled environment with minimal air exposure. This can be achieved by working in a glove box filled with inert gas or by using rapid transfer techniques to move the samples from the preparation area to the XPS instrument.

-

Immediate Testing: Once prepared, samples should be transferred directly to the XPS instrument for analysis. Any delay can lead to oxidation or contamination, which will skew the results.

-

Controlled Storage: If immediate testing is not feasible, samples should be stored in a vacuum or inert atmosphere to prevent degradation. This ensures that the samples remain in their original state until they can be analyzed.

By adhering to these practices, researchers can ensure that the XPS data collected for these sensitive elements accurately reflects their chemical states, leading to more reliable and reproducible results.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- XRD Sample Holder X-ray Diffractometer Powder Slide

- Electrode Polishing Material for Electrochemical Experiments

Related Articles

- What is xrf analysis and how to making pressed xrf pellets

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- Effective Preparation of Samples for XRF Analysis via Pressed Pellets Method

- Operating of Automatic Lab xrf Pellet Press

- Understanding Cold Isostatic Pressing (CIP) and Its Advantages