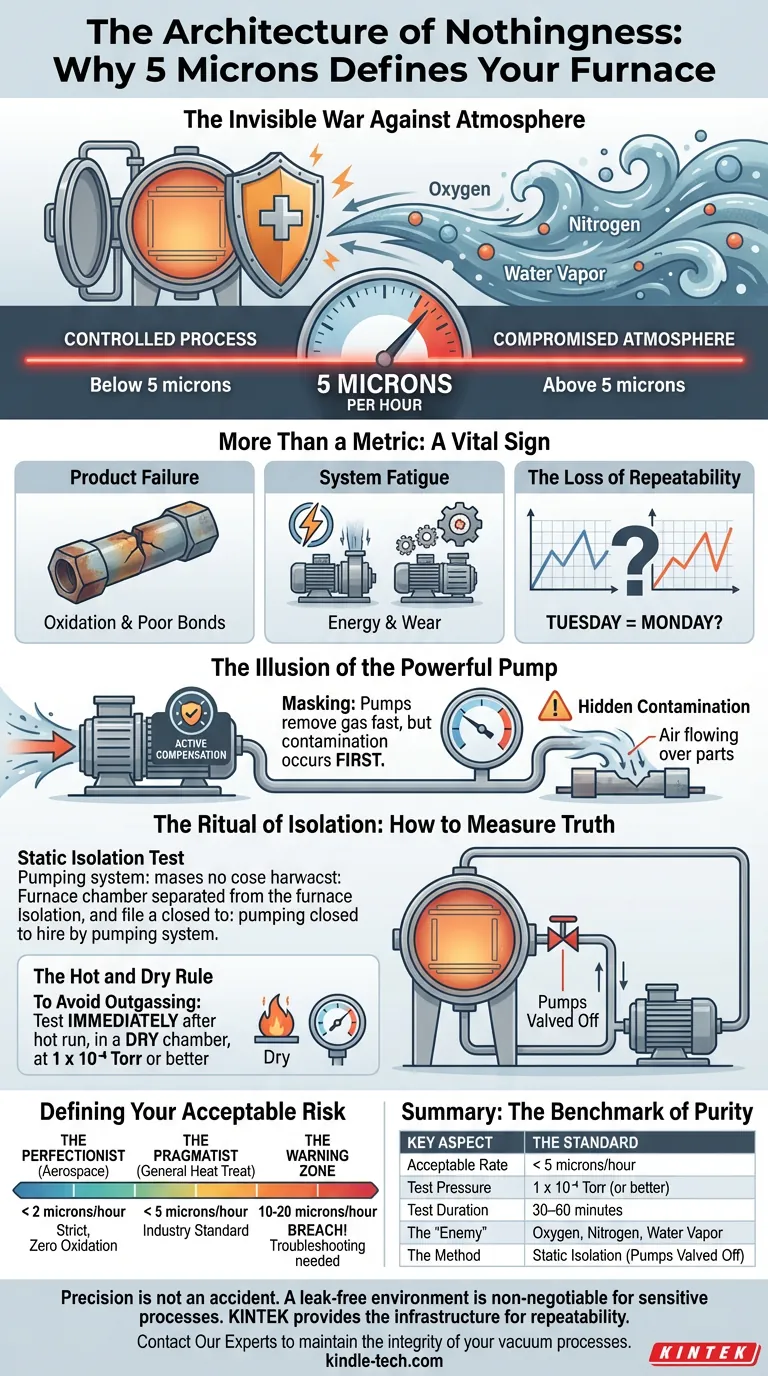

The Invisible War Against Atmosphere

In the world of high-vacuum metallurgy, we are essentially fighting a war against nature. Nature abhors a vacuum; it wants to rush in, oxidize, and equalize.

Your vacuum furnace is the shield.

When we talk about leak rates, we aren't just discussing a technical specification found in a manual. We are discussing the structural integrity of that shield.

An acceptable leak rate for a high-vacuum furnace is typically less than 5 microns per hour.

This number is the dividing line between a controlled scientific process and a chaotic one. If you cross it, you are no longer operating in a vacuum; you are operating in a compromised atmosphere.

More Than a Metric: A Vital Sign

Atul Gawande often writes about how complex systems fail not because of a lack of skill, but because of a lack of standardized vigilance. A vacuum furnace is no different.

The leak rate is the furnace’s fundamental health indicator.

A reading below 5 microns/hour tells you the vessel is sealed tight enough to prevent the atmosphere—specifically nitrogen, oxygen, and water vapor—from entering.

If you ignore this metric, three things happen, compounding over time:

- Product Failure: Oxygen causes discoloration and poor metallurgical bonds. You lose the part.

- System Fatigue: Your pumps must work overtime to fight the incoming air, increasing energy consumption and wear.

- The Loss of Repeatability: This is the psychological cost. Without a confirmed leak rate, you cannot guarantee that Tuesday’s run will match Monday’s run. You are guessing.

The Illusion of the Powerful Pump

There is a common trap in vacuum processing: Masking.

Modern pumping systems are incredibly powerful. They are often strong enough to overcome a moderate leak, removing gas almost as fast as it enters. The pressure gauge might look fine while the pump is running.

But the contamination is still happening. The air is still flowing over your parts before the pump can grab it.

This is why dynamic vacuum levels are deceiving. You cannot measure the integrity of a vessel while the pumps are actively compensating for its flaws.

The Ritual of Isolation: How to Measure Truth

To know the truth about your furnace, you must stop the fight. You must isolate the chamber.

A proper leak rate test isolates the pumping system from the furnace chamber using a main valve. This ensures you are measuring the gas entering the chamber from the outside, not the performance of the pumps.

The "Hot and Dry" Rule

Physics can play tricks on us. Outgassing—the release of water vapor molecules trapped on internal surfaces—looks exactly like a leak on a pressure gauge.

To avoid a false positive, the test must be performed strictly:

- Immediately after a hot run (burn-out).

- In a dry chamber.

- Ideally at a vacuum level of 1 x 10⁻⁴ Torr or better.

If the furnace is cold or humid, you aren't measuring a leak; you are measuring moisture evaporation.

Defining Your Acceptable Risk

Not all vacuums are created equal. The standard you accept should match the stakes of your application.

- The Perfectionist (Aerospace): For critical brazing where zero oxidation is tolerated, the standard is strict. Aim for < 2 microns/hour.

- The Pragmatist (General Heat Treat): The industry standard of < 5 microns/hour is your reliable benchmark.

- The Warning Zone: If you drift into 10–20 microns/hour, you have a breach. You are no longer processing; you are troubleshooting.

Summary: The Benchmark of Purity

| Key Aspect | The Standard |

|---|---|

| Acceptable Rate | < 5 microns per hour |

| Test Pressure | 1 x 10⁻⁴ Torr (or better) |

| Test Duration | 30–60 minutes |

| The "Enemy" | Oxygen, Nitrogen, Water Vapor |

| The Method | Static Isolation (Pumps Valved Off) |

Conclusion

Precision is not an accident. It is the result of rigid standards applied to invisible forces.

A leak-free environment is non-negotiable for sensitive processes like brazing and heat treating. At KINTEK, we understand that your equipment is the only thing standing between your product and the atmosphere.

Whether you need high-performance lab equipment or the consumables to keep them running, we provide the infrastructure for repeatability.

Contact Our Experts to discuss how we can help you maintain the integrity of your vacuum processes.

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

Related Articles

- Vacuum Laboratory Furnaces in Advanced Materials Research

- Exploring the Advanced Capabilities of Spark Plasma Sintering (SPS) Furnaces

- Introducing the Lab Vacuum Tube Furnaces

- Comprehensive Guide to Vacuum Hot Press Furnace Application

- Vacuum Induction Furnace Fault Inspection: Essential Procedures and Solutions