Articles

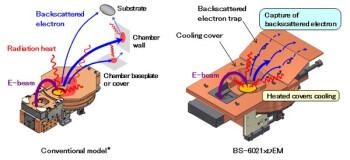

Electron Beam Evaporation Coating Technology and Material Selection

10 months agoAn in-depth look at the principles and applications of electron beam evaporation coating technology, including material selection and various fields of application.

Learn More

Electron Beam Evaporation: Advanced Thin Film Creation

10 months agoExplores the technology and applications of electron beam evaporation in thin film production.

Learn More

Electron Beam Evaporation Coating: Principles, Characteristics, and Applications

10 months agoAn in-depth analysis of electron beam evaporation coating technology, its advantages, disadvantages, and applications in thin film manufacturing.

Learn More

Electron Beam Evaporation Technology in Vacuum Coating

10 months agoAn in-depth look at electron beam evaporation, its types, advantages, and disadvantages in vacuum coating processes.

Learn More

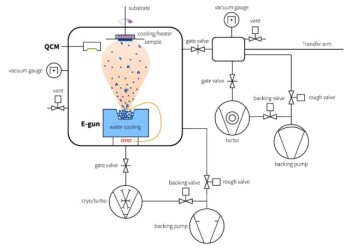

Comprehensive Overview of Vacuum Evaporation Systems

10 months agoAn in-depth look at vacuum evaporation systems, their principles, components, and applications.

Learn More

Understanding Evaporation Plating, Sputtering Plating, and Ion Plating

10 months agoA detailed comparison of evaporation plating, sputtering plating, and ion plating techniques, their principles, types, and characteristics.

Learn More

Challenges in the Development and Application of Tantalum in Vacuum Deposition Equipment

10 months agoThis article discusses the role of tantalum in vacuum deposition equipment, focusing on its properties, manufacturing challenges, and its critical applications in industries like OLED screen production.

Learn More

Exploring Various Vacuum Coating Technologies: Evaporation, Sputtering, and Ion Plating

10 months agoThis article delves into the different vacuum coating technologies, focusing on evaporation, sputtering, and ion plating, detailing their principles, advantages, and applications.

Learn More

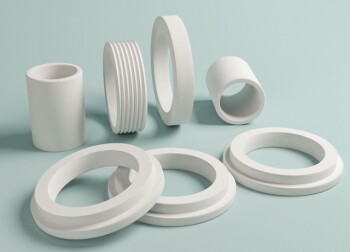

Understanding Oxide Ceramics: Concepts, Classification, and Applications

10 months agoThis article delves into the concept, classification, and diverse applications of oxide ceramics, highlighting their significance in various high-tech fields.

Learn More

Hexagonal Boron Nitride: Enhancing Performance in Composite Ceramic Materials

10 months agoExplores the role of h-BN in various composite ceramics, highlighting its properties and applications.

Learn More

Understanding Evaporation Boats in Vacuum Coating

10 months agoAn in-depth look at evaporation boats, their materials, arrangement, temperature control, and corrosion issues in vacuum coating processes.

Learn More

Types of Evaporation Sources for Evaporative Coating

10 months agoExplore different evaporation sources used in thin film deposition, including filaments, crucibles, and evaporation boats.

Learn More

Preparation Technologies and Applications of High-Purity Metals

10 months agoAn in-depth look at the definition, preparation technologies, and applications of high-purity metals.

Learn More

Comparison of Flat and Rotary Sputtering Targets

10 months agoAnalyzes the characteristics, advantages, and disadvantages of flat and rotary sputtering targets in material research.

Learn More

Comparison of Planar and Rotating Silicon Targets in Thin Film Deposition

10 months agoAn in-depth comparison of the advantages and disadvantages of planar and rotating silicon targets, focusing on their characteristics and application scenarios in thin film deposition technology.

Learn More

Emerging Green Solvents in Photovoltaic Module Recycling

10 months agoExploring the shift towards green solvents in PV module recycling, focusing on deep eutectic solvents and their advantages.

Learn More

Recovery and Extraction of Indium Metal from ITO Target Waste Materials

10 months agoThis article discusses the methods and processes for recovering high-purity indium from ITO target waste, including chemical and electrolytic purification techniques.

Learn More

Application, Preparation, and Recovery of Precious Metal Targets in Semiconductor Manufacturing

10 months agoDiscusses the use, preparation, and recycling of precious metal targets in semiconductor manufacturing.

Learn More

Advancements in Rare Earth Materials and Recycling Technologies

10 months agoExplores new rare earth materials and recycling technologies, focusing on polishing, high-purity metals, and various recycling methods.

Learn More

Understanding Hot Isostatic Pressing in PVD Sputtering Targets

10 months agoExplores the role of hot isostatic pressing in enhancing the quality and uniformity of PVD sputtering targets, focusing on manufacturing techniques and benefits.

Learn More

Manufacturing Sputtering Targets Using Powder Metallurgy

10 months agoDetailed process and applications of powder metallurgy in manufacturing sputtering targets.

Learn More

AI Chip Advancement Driven by Metallic New Materials

10 months agoExplores how AI chip upgrades are fueled by new metal materials, impacting computing power and semiconductor manufacturing.

Learn More

Sputtering Targets for Decorative Coatings

10 months agoOverview of various sputtering targets used in decorative coatings for their unique properties and applications.

Learn More

Comprehensive Classification and Application of Magnetron Sputtering Targets

10 months agoThis article details the classification, applications, and principles of magnetron sputtering targets across various industries.

Learn More

Comprehensive Analysis of Magnetron Sputtering Targets

10 months agoAn in-depth exploration of magnetron sputtering targets, their requirements, principles, types, and performance factors.

Learn More

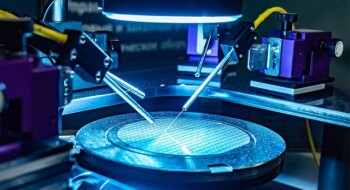

High-Purity Sputtering Targets for Integrated Circuit Manufacturing

10 months agoThis article discusses the high-purity requirements and applications of various sputtering targets in integrated circuit manufacturing, focusing on metals and alloys used in different technology nodes.

Learn More

Introduction to the Casting Process for Sputtering Targets

10 months agoA comprehensive guide to the casting process for sputtering targets, including suitable materials, advantages, and detailed process steps.

Learn More

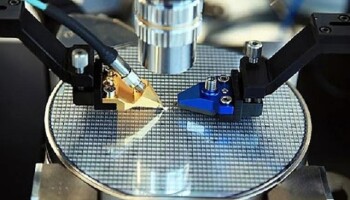

Introduction to Sputtering Targets

10 months agoAn overview of sputtering targets, their types, and key parameters like purity, density, and grain size.

Learn More

Causes of Orange Peel on Polysilicon Tube Sputtering Targets

10 months agoExplores factors leading to orange peel on sputtering targets, including process parameters, target quality, and equipment issues.

Learn More

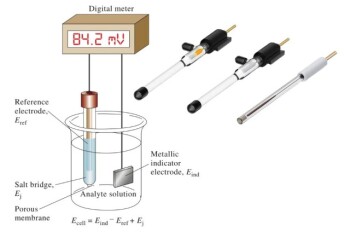

Guide to Reference Electrodes in Electrochemical Measurements

10 months agoDetailed guide on reference electrodes, their use, maintenance, checking methods, regeneration, storage, and applications.

Learn More