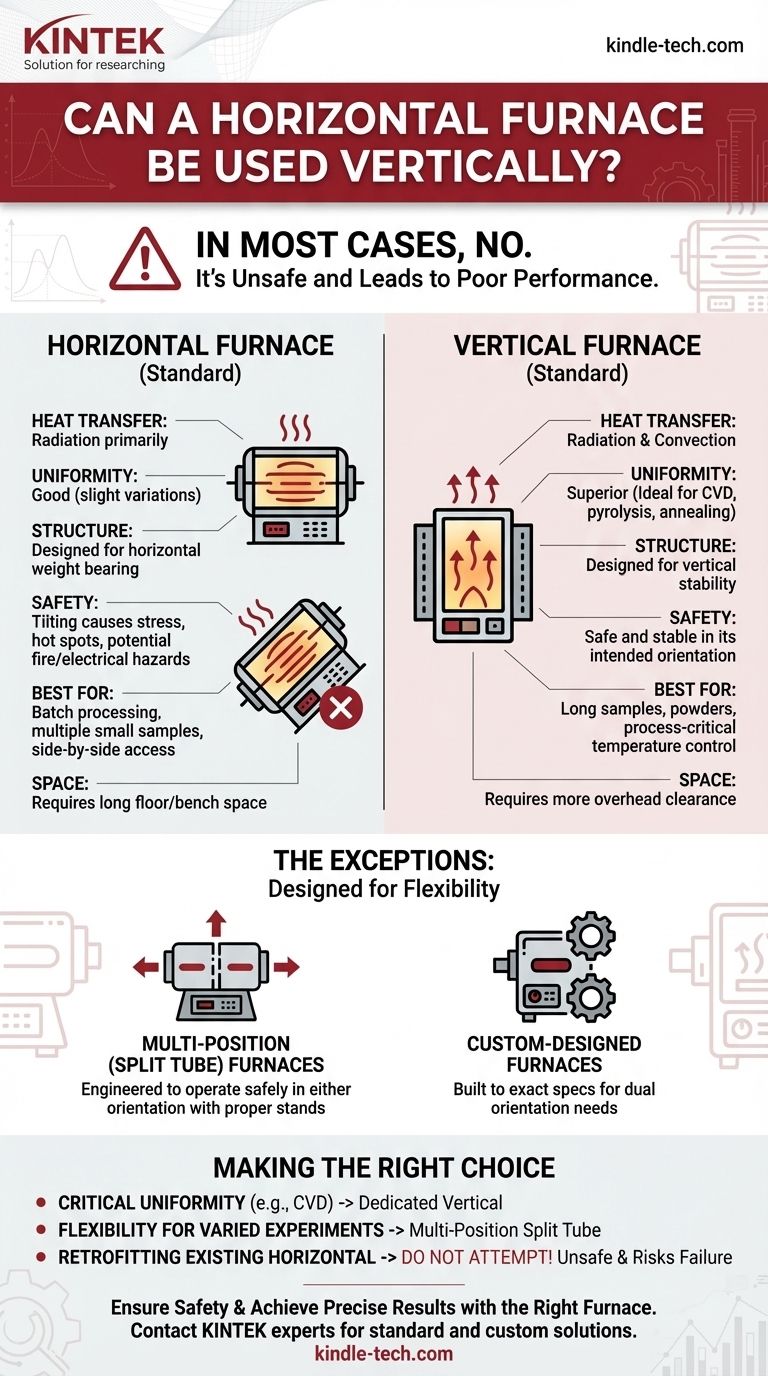

In most cases, you cannot use a furnace designed exclusively for horizontal operation in a vertical position. Standard horizontal furnaces are engineered for a specific orientation, and altering it can lead to severe safety hazards, equipment damage, and poor performance. However, certain models, such as multi-position split tube furnaces or custom-built systems, are specifically designed to operate in either orientation.

The orientation of a furnace is not a simple matter of placement; it is a fundamental design characteristic that dictates heat transfer, temperature uniformity, and structural safety. Forcing a furnace into an orientation it was not built for is unsafe and will compromise your results.

Why Orientation is a Fundamental Design Choice

A furnace's specified orientation is determined by core engineering principles. Attempting to bypass these design constraints introduces significant risk and performance issues.

Heat Transfer and Temperature Uniformity

In a vertical tube furnace, heat rises naturally via convection in addition to radiating from the heating elements. This combination creates a highly uniform temperature zone along the sample's length, which is critical for sensitive processes.

In a horizontal furnace, heat transfer relies primarily on radiation. This can lead to slight temperature variations along the length of the tube, as convection does not play as significant a role in distributing heat evenly.

Structural Integrity and Safety

A furnace's frame, insulation, and internal component mounts are designed to bear weight in a specific orientation. Tilting a horizontal furnace vertically puts stress on parts not designed to handle it, potentially leading to structural failure.

Most importantly, heating elements and insulation may shift, creating hot spots on the furnace casing or exposing internal wiring, which presents a significant fire and electrical hazard.

Sample Handling and Process Flow

The orientation dictates how you interact with your samples. Vertical furnaces are ideal for processing long samples, powders, or materials in crucibles, where gravity aids in loading and positioning.

Horizontal furnaces are often better suited for processing multiple smaller samples side-by-side or for processes where a sample is pushed or pulled through the heat zone.

The Exceptions: Furnaces Designed for Flexibility

While you cannot repurpose a standard horizontal furnace, some systems are intentionally built for dual-orientation use.

Multi-Position (Split Tube) Furnaces

Some split tube furnaces are explicitly designed to be used both horizontally and vertically. These models typically come with different mounting stands or frames that safely support the furnace body in either position. They are engineered to ensure performance and safety are maintained regardless of orientation.

Custom-Designed Furnaces

For highly specific industrial or research applications, manufacturers can create custom vacuum or tube furnaces built to your exact specifications. This includes designing a unit that can be safely and effectively operated in either a vertical or horizontal position to meet unique process requirements.

Understanding the Trade-offs: Vertical vs. Horizontal

Choosing an orientation is about aligning the furnace's strengths with your application's needs.

Key Advantage of Vertical: Process Control

The superior temperature uniformity of a vertical furnace makes it the standard for processes like Chemical Vapor Deposition (CVD), pyrolysis, crystal growth, and annealing, where precise thermal control is non-negotiable.

Key Advantage of Horizontal: Batch Processing and Accessibility

Horizontal furnaces can make it easier to load and unload trays of multiple small components. The entire length of the process tube is also often more accessible compared to a top-loading vertical furnace.

Space and Footprint Considerations

This is the most obvious difference. A vertical furnace requires more overhead clearance but uses minimal floor space. A horizontal furnace requires a longer, uninterrupted stretch of bench or floor space but has a lower profile.

Making the Right Choice for Your Application

Your final decision must be driven by your specific goals and constraints.

- If your primary focus is process-critical temperature uniformity (e.g., CVD, nanostructure growth): A dedicated vertical furnace is the correct and most reliable tool for the job.

- If your primary focus is flexibility for varied lab experiments: A multi-position split tube furnace that is certified for both orientations provides the most versatility.

- If your primary focus is retrofitting an existing horizontal furnace for vertical use: Do not attempt this. The risks of equipment failure and safety hazards are too high. Contact the manufacturer about a purpose-built solution.

Choosing the correct furnace orientation from the start is the foundation for achieving safe, repeatable, and high-quality results.

Summary Table:

| Aspect | Horizontal Furnace | Vertical Furnace |

|---|---|---|

| Primary Heat Transfer | Radiation | Radiation & Convection |

| Temperature Uniformity | Good | Superior (Ideal for CVD, etc.) |

| Best For | Batch processing, multiple small samples | Long samples, powders, process-critical applications |

| Space Requirement | Longer floor/bench space | More overhead clearance |

| Flexibility | Fixed orientation (unless multi-position model) | Fixed orientation (unless multi-position model) |

Ensure your lab's safety and achieve precise results with the right furnace. Choosing the correct equipment is critical for your processes. KINTEK specializes in lab equipment and consumables, serving laboratory needs with a range of standard and custom horizontal, vertical, and multi-position tube furnaces. Our experts can help you select the perfect furnace for your specific application, ensuring optimal performance and safety. Contact our team today for a consultation and let us provide the reliable solution your research deserves.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What types of atmospheres are possible within a vacuum tube furnace? Master Precise Material Processing Environments

- How is a laboratory tube heating furnace configured for high-temperature failure studies? Master Reactor Precision

- What protections do high vacuum tube furnaces offer for DMR? Ensure Precise Atmosphere Control & Catalyst Purity

- Why is a tube furnace required for Li6PS5Cl solid-state electrolytes? Achieve High Ionic Conductivity & Purity

- How does 200 Pa nitrogen affect iron nitride annealing? Achieve Precise Phase Transformation Control

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- Why is a vertical quartz tube reaction furnace selected for metal dusting experiments? Precision in Lab Simulation

- How does a temperature-controlled tube furnace influence the performance of biochar adsorbents? Optimize Pore Structure