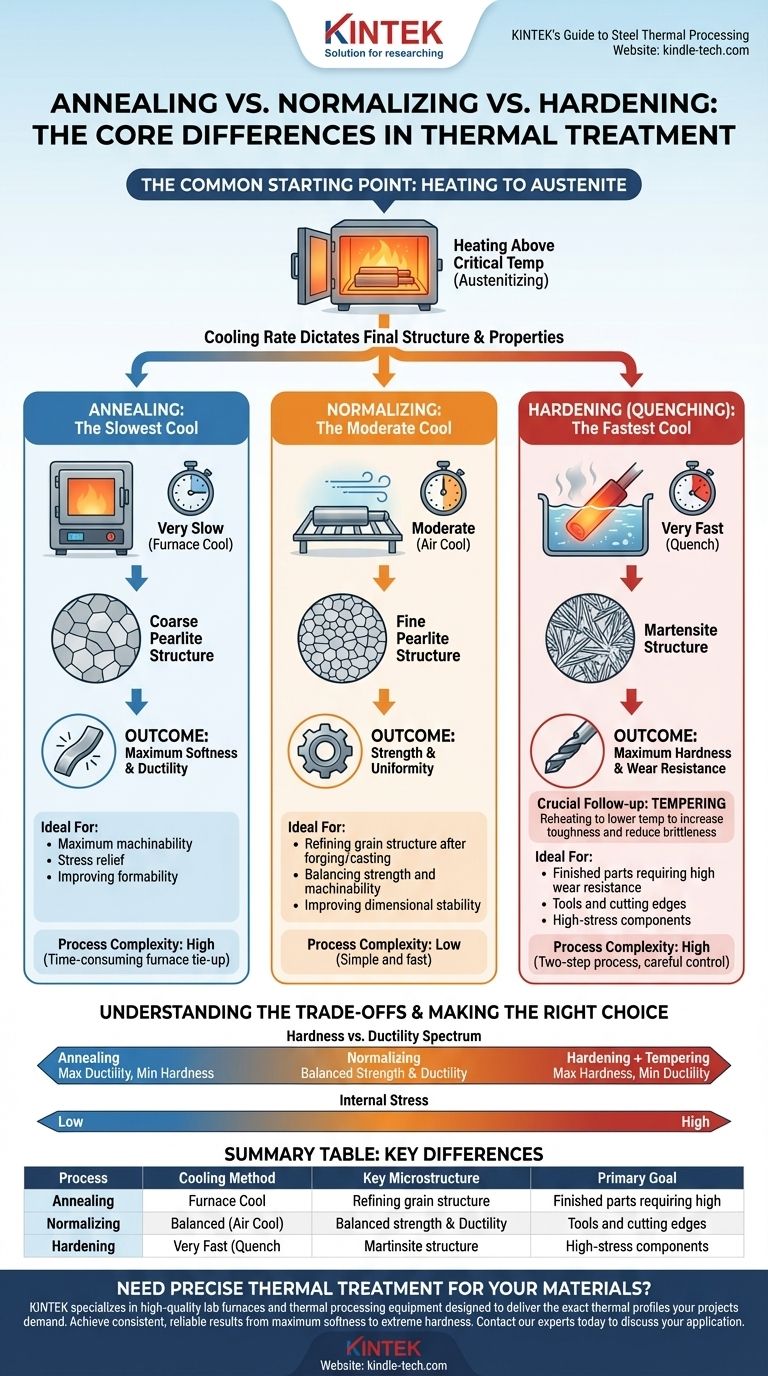

At their core, the three primary thermal treatments for steel—annealing, normalizing, and hardening—all start by heating the metal to a specific high temperature. The fundamental difference between them is the rate at which the steel is cooled from that temperature. This cooling speed directly dictates the metal's final microstructure, which in turn determines its mechanical properties like hardness, strength, and ductility.

The choice between annealing, normalizing, and hardening isn't about the heating; it's about controlling the cooling. Slow cooling creates softness (annealing), moderate cooling creates strength (normalizing), and rapid cooling creates extreme hardness (hardening).

The Foundation: Heating Above the Critical Temperature

All three of these heat treatment processes begin with the same critical first step. The goal is to create a uniform internal structure from which the final desired properties can be formed.

Why Heating Matters: Creating Austenite

To change the properties of steel, you must first heat it above its critical temperature (typically between 750-900°C or 1400-1650°F, depending on the alloy).

Holding the steel at this temperature forces its internal crystalline structure to transform into a state called austenite. In this state, the carbon and iron atoms form a uniform, solid solution, erasing the previous microstructure and setting the stage for transformation.

The Common Starting Point

Think of the austenitizing step as a "factory reset" for the steel's internal structure. Once the steel is uniformly austenitic, the specific cooling method that follows will determine its final characteristics.

The Defining Factor: Cooling Rate and Final Structure

The speed of cooling is the most important variable in heat treatment. Each method produces a distinct microstructure with unique properties.

Annealing: The Slowest Cool

In annealing, the steel is cooled extremely slowly, typically by leaving it inside the furnace and shutting it off, allowing it to cool over many hours or even days.

This slow cooling allows the crystalline structure to form with minimal stress, resulting in a very soft and coarse microstructure called pearlite.

Normalizing: The Moderate Cool

For normalizing, the steel is removed from the furnace and allowed to cool in still air at room temperature.

This moderately fast cooling produces a more refined and stronger microstructure, known as fine pearlite. The structure is more uniform than in an untreated piece of steel.

Hardening: The Fastest Cool (Quenching)

Hardening requires a very rapid cool, achieved by plunging the hot steel into a liquid medium like water, brine, or oil. This process is called quenching.

This extreme cooling rate traps the carbon atoms within the iron crystals, creating a very hard, brittle, needle-like structure called martensite.

A Deeper Look at Each Process and its Outcome

Understanding the goal of each treatment is key to selecting the right one for your application.

Annealing: Maximum Softness and Ductility

The primary goal of annealing is to make steel as soft as possible. This reduces internal stresses, increases ductility (the ability to deform without breaking), and significantly improves machinability.

It is often used as an intermediate step to make a part easier to form or machine before it undergoes a final hardening treatment.

Normalizing: Strength and Uniformity

Normalizing is often performed to refine the grain structure of steel that has been subjected to processes like forging or casting, which can create non-uniformities.

The resulting material is stronger and harder than annealed steel but is not as brittle as hardened steel. It provides a good balance of strength and machinability.

Hardening and Tempering: Maximum Hardness and Toughness

Hardening produces steel with maximum hardness and wear resistance. However, the resulting martensitic structure is extremely brittle and contains high internal stresses, making it unsuitable for most applications.

For this reason, hardening is almost always followed by a second process called tempering. Tempering involves reheating the hardened part to a much lower temperature (e.g., 200-650°C or 400-1200°F) to relieve stress and impart toughness, reducing brittleness at the cost of some hardness.

Understanding the Trade-offs

No single heat treatment is universally "best." The choice always involves balancing competing properties.

The Hardness vs. Ductility Spectrum

The core trade-off is between hardness and ductility.

- Annealing provides maximum ductility but minimum hardness.

- Hardening and Tempering provides maximum hardness but limited ductility.

- Normalizing sits in the middle, offering a good balance of both.

Internal Stress and Dimensional Stability

Rapid cooling (quenching) induces significant internal stress, which can cause parts to warp, distort, or even crack. Slower cooling rates, like those in annealing and normalizing, result in far more dimensionally stable components.

Cost and Process Complexity

Annealing is the most time-consuming due to the slow furnace cooling, which can tie up equipment for long periods. Hardening and tempering is a two-step process that requires careful control to avoid defects, adding complexity. Normalizing is often the simplest and fastest of the three.

Making the Right Choice for Your Goal

Your application's requirements will dictate the correct thermal treatment.

- If your primary focus is maximum machinability and stress relief: Choose annealing to make the steel as soft and workable as possible.

- If your primary focus is refining grain structure and achieving a good balance of strength and ductility: Choose normalizing, especially after forging or casting.

- If your primary focus is maximum hardness and wear resistance for a finished part: Choose hardening followed by tempering to create a durable component that can withstand high stress and abrasion.

By understanding how the cooling rate manipulates the internal structure of steel, you gain direct control over its final performance.

Summary Table:

| Process | Cooling Method | Key Microstructure | Primary Goal |

|---|---|---|---|

| Annealing | Very Slow (Furnace Cool) | Coarse Pearlite | Maximum Softness & Ductility |

| Normalizing | Moderate (Air Cool) | Fine Pearlite | Strength & Uniformity |

| Hardening | Very Fast (Quench) | Martensite | Maximum Hardness & Wear Resistance |

Need precise thermal treatment for your materials?

Understanding the differences between annealing, normalizing, and hardening is the first step. Achieving consistent, reliable results requires precise control over heating and cooling cycles, which is where the right equipment makes all the difference.

KINTEK specializes in high-quality lab furnaces and thermal processing equipment designed to deliver the exact thermal profiles your projects demand. Whether you are developing new materials, processing metal components, or conducting research, our solutions help you achieve the desired material properties—from maximum softness to extreme hardness—with repeatability and efficiency.

Let's discuss your application requirements. Contact our thermal experts today to find the ideal furnace for your annealing, normalizing, or hardening processes.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results