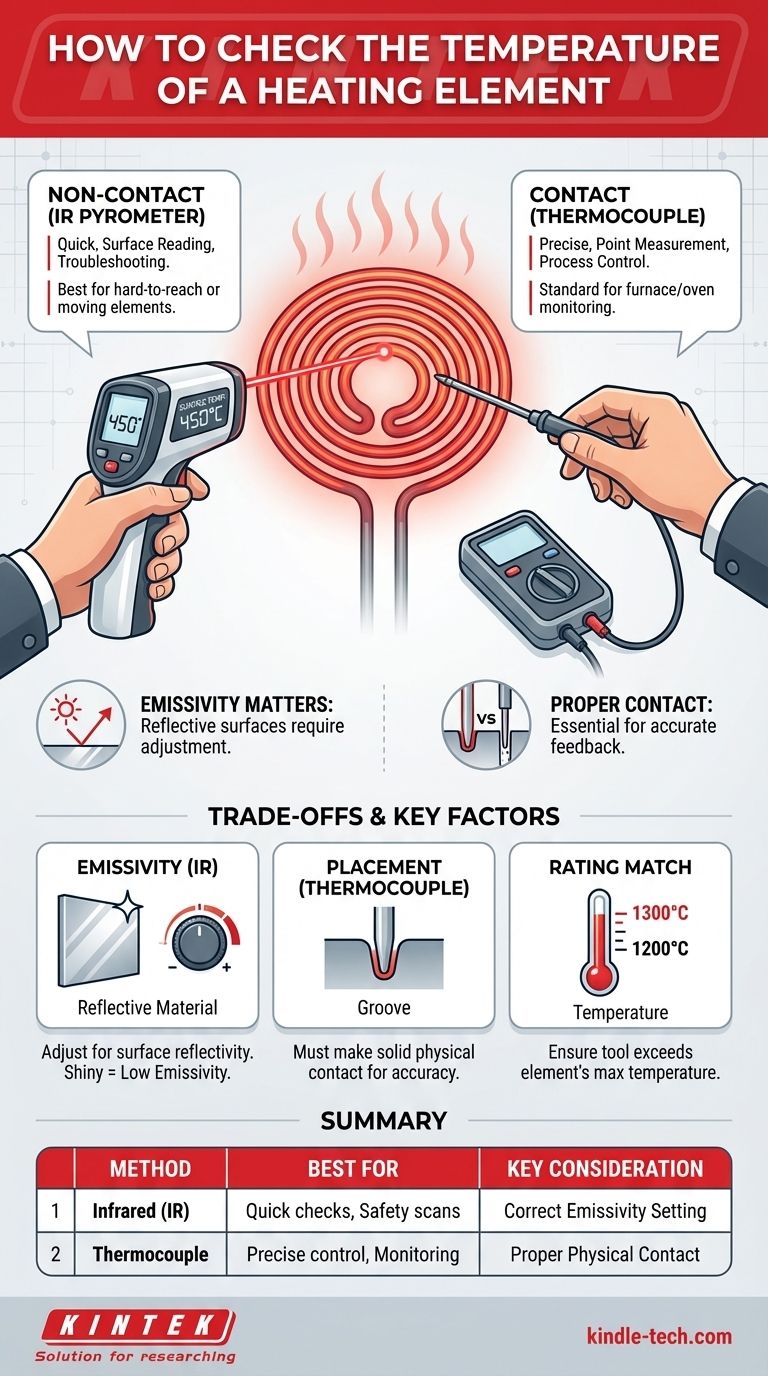

To check the temperature of a heating element, you use one of two primary methods: a non-contact infrared (IR) pyrometer for a fast surface reading from a distance, or a contact-based thermocouple for a precise measurement directly on or near the element. The choice depends entirely on your specific goal, accessibility to the element, and the required level of precision.

The core challenge is not just measuring the heat, but understanding what that measurement represents. A non-contact reading tells you the element's surface temperature, while a contact reading gives you the temperature at a single, specific point, which is often more useful for process control.

Choosing Your Measurement Method

The right tool depends on whether you are troubleshooting, calibrating a system, or conducting a safety check. Each method provides a different type of data with its own distinct advantages.

Non-Contact Measurement: Infrared (IR) Pyrometers

An IR pyrometer, also known as an infrared thermometer or thermal gun, measures the thermal radiation an object emits without touching it. You simply point the device at the heating element and read the temperature.

This method is ideal for quick spot-checks, measuring elements that are in motion, or checking components that are dangerously hot or difficult to reach.

Contact Measurement: Thermocouples

A thermocouple is a sensor made of two dissimilar metal wires joined at one end. When this junction is heated, it produces a small voltage that corresponds to a specific temperature.

This method is the standard for precise process control, such as inside a furnace or kiln. The thermocouple is typically placed in a fixed position to provide continuous, accurate feedback to a control system.

Understanding the Trade-offs and Key Factors

Simply taking a reading is not enough. To get a measurement you can trust, you must be aware of the limitations and variables that can affect your results.

The Critical Role of Emissivity (For IR)

The accuracy of an IR pyrometer depends heavily on the emissivity of the heating element's surface. Emissivity is a measure of how effectively a surface radiates energy as heat, rated on a scale from 0 to 1.

Shiny, reflective surfaces have low emissivity and can trick an IR gun into giving a falsely low reading. Many pyrometers have an adjustable emissivity setting to compensate for this; otherwise, applying a small spot of high-emissivity paint or tape can provide a more reliable target.

Proper Placement and Contact (For Thermocouples)

For a thermocouple to be accurate, its sensing tip must make solid physical contact with the surface being measured or be properly positioned within the heated environment.

A loose or poorly placed thermocouple will be influenced by the surrounding air temperature, leading to inaccurate readings that do not reflect the true temperature of the heating element.

Matching the Tool to the Element's Rating

Heating elements are designed for specific temperature ranges. For example, standard resistance wire is often rated for 1000-1200℃, while silicon carbide elements can reach 1300℃ or higher.

You must ensure your measurement tool is rated for a temperature range that exceeds the element's maximum capability. Using a thermocouple or pyrometer beyond its specified limit will destroy the sensor and produce invalid data.

Making the Right Choice for Your Goal

Select your method based on the information you actually need to solve your problem.

- If your primary focus is quick troubleshooting or safety scans: Use a handheld IR pyrometer to quickly identify if an element is energized or if there are hot spots.

- If your primary focus is precise process control inside a furnace or oven: Use a properly installed thermocouple integrated with your control system for stable and accurate feedback.

- If your primary focus is design validation or calibration: Consider using both methods. A thermocouple provides a precise anchor point while an IR camera can give you a complete thermal map of the element's surface.

Ultimately, choosing the correct measurement tool is the first step toward controlling your thermal process with confidence.

Summary Table:

| Method | Best For | Key Consideration |

|---|---|---|

| Infrared (IR) Pyrometer | Quick checks, hard-to-reach elements, safety scans | Requires correct emissivity setting for accuracy |

| Thermocouple | Precise process control, furnace/oven monitoring | Needs proper physical contact and placement |

Need to ensure your heating elements are operating at peak performance? KINTEK specializes in lab equipment and consumables, including high-precision temperature measurement tools. Our experts can help you select the right pyrometer or thermocouple for your specific application, ensuring accurate temperature control and process reliability. Contact us today to discuss your laboratory's heating and temperature monitoring needs!

Visual Guide

Related Products

- Bomb Type Probe for Steelmaking Production Process

- Shaking Incubators for Diverse Laboratory Applications

- 5L Chilling Circulator Cooling Water Bath Circulator for Low Temperature Constant Temperature Reaction Bath

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Thermally Evaporated Tungsten Wire for High Temperature Applications

People Also Ask

- How hot does a quartz test tube get? Unlock Superior Heat Resistance for Your Lab

- What is a thermistor on a heat press? The Key to Consistent, Professional Transfers

- What is the most accurate temperature sensor? Why RTDs Lead in Precision and Stability

- Will stainless steel work as a crucible? The Surprising Dangers of Using the Wrong Material

- What is refractory material made of? Key Components for Extreme Heat Resistance