At its core, a thermistor on a heat press is the machine's digital thermometer. This small but critical electronic sensor constantly measures the temperature of the heat platen, ensuring the heat you set on the display is the heat being applied to your garment.

The thermistor is the key component in your heat press's temperature control system. Its accuracy is the single most important factor in achieving a consistent, professional-grade transfer that lasts.

How a Heat Press Manages Heat

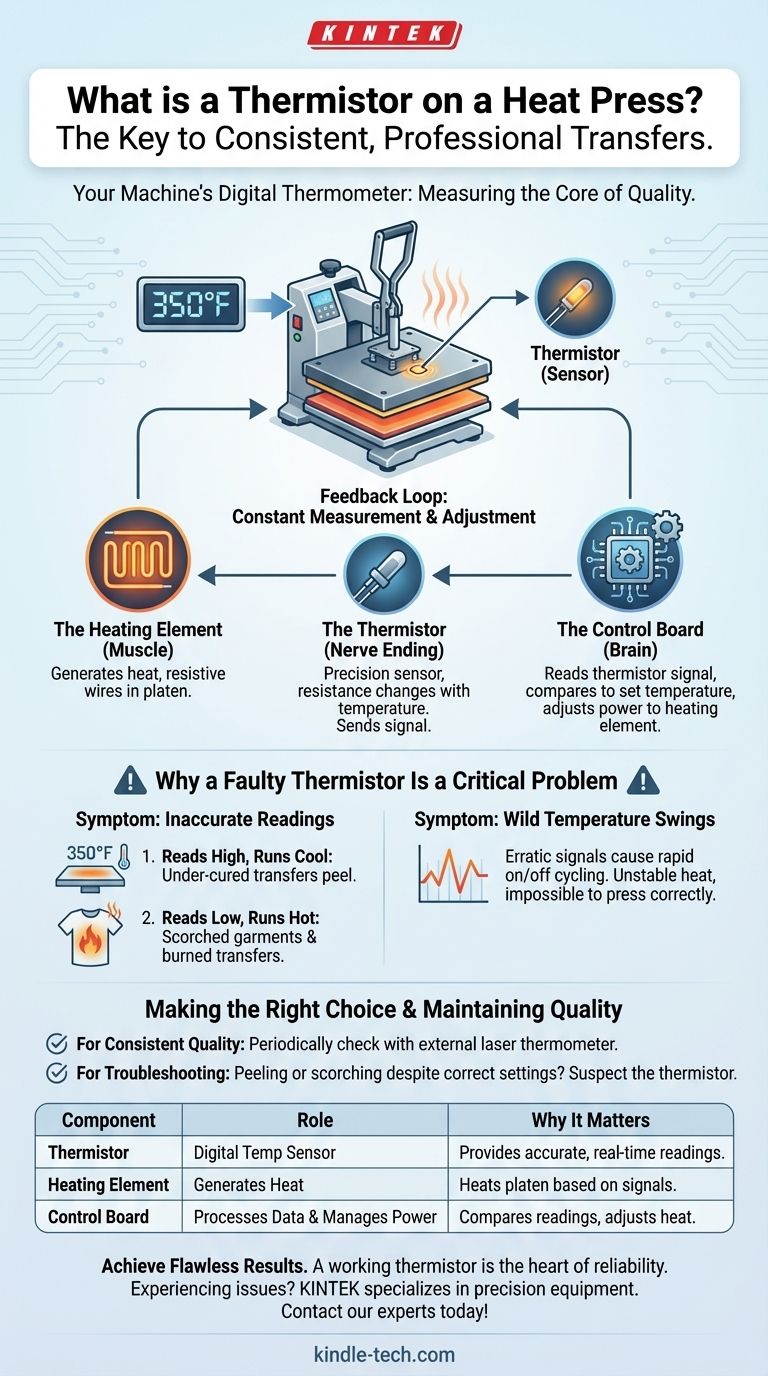

A heat press must deliver precise, stable heat to work correctly. This is achieved through a simple but effective feedback loop between three key components.

The Heating Element: The "Muscle"

The heating element is the part that gets hot. It's a network of resistive wires embedded within the upper platen that converts electrical energy into thermal energy, much like the element in an electric stove.

The Thermistor: The "Nerve Ending"

The thermistor is a special type of resistor whose electrical resistance changes predictably with temperature. It's mounted directly to the heating platen to get an accurate reading.

Think of it as a sensitive nerve ending. As the platen heats up, the thermistor's resistance changes, sending a precise signal about the current temperature.

The Control Board: The "Brain"

The control board is the brain of the operation. It reads the electrical signal from the thermistor to know the platen's exact temperature.

It then compares this real-time temperature to the target temperature you set. If it's too cool, the board sends more power to the heating element. If it's too hot, it cuts the power. This constant cycle of measuring and adjusting happens many times per second.

Why a Faulty Thermistor Is a Critical Problem

When a thermistor begins to fail, it provides the control board with incorrect information. This directly compromises the two most common causes of failed transfers: inaccurate temperature and temperature fluctuation.

Symptom: Inaccurate Readings

A failing thermistor might tell the control board the platen is 350°F when it's actually only 320°F. This leads to under-cured transfers that will peel off after the first wash.

Conversely, it could read low, causing the board to overheat the platen. This can scorch the garment or burn the transfer, ruining both.

Symptom: Wild Temperature Swings

An unstable thermistor sends erratic signals, causing the control board to rapidly turn the heating element on and off. The display may show wild temperature swings, making it impossible to apply a transfer correctly.

The Result: Wasted Time and Materials

Ultimately, a faulty thermistor means you can no longer trust your machine. Every press becomes a gamble, leading to wasted garments, vinyl, and ink, which is far more costly than the component itself.

Making the Right Choice for Your Goal

Understanding this component allows you to better diagnose issues and maintain the quality of your work.

- If your primary focus is consistent quality: Periodically check your heat press's temperature with an external laser thermometer to ensure the thermistor is still providing an accurate reading.

- If your primary focus is troubleshooting a press: If you are experiencing peeling transfers or scorched garments despite using the correct settings, a failing thermistor is the most likely culprit.

This tiny sensor is the foundation of your heat press's reliability, turning it from a simple hot plate into a precision tool.

Summary Table:

| Component | Role in Heat Press | Why It Matters |

|---|---|---|

| Thermistor | Digital temperature sensor | Provides accurate, real-time temperature readings to the control board. |

| Heating Element | Generates heat | Heats the platen based on signals from the control board. |

| Control Board | Processes data and manages power | Compares thermistor readings to the set temperature and adjusts the heating element. |

Achieve flawless, consistent results with every press. A properly functioning thermistor is the heart of a reliable heat press. If you're experiencing peeling transfers or scorched materials, your thermistor may be failing. The team at KINTEK specializes in lab equipment and consumables, including precision tools for heat application. We can help you diagnose issues and ensure your equipment performs like new. Contact our experts today for a consultation and keep your projects on track!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- Why is a laboratory hot press required for Oxygen Depolarized Cathodes? Ensure Precision Molding and Conductivity.

- What role does a hot press play in treating the CAL-GPE interface? Optimize Performance for Flexible Lithium Batteries

- Why is a laboratory hot press necessary for the production of plastic crystal polymer electrolyte reinforced membranes?

- How is pressure generated and applied in a hot press? Master High-Intensity Hydraulic & Pneumatic Systems

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?