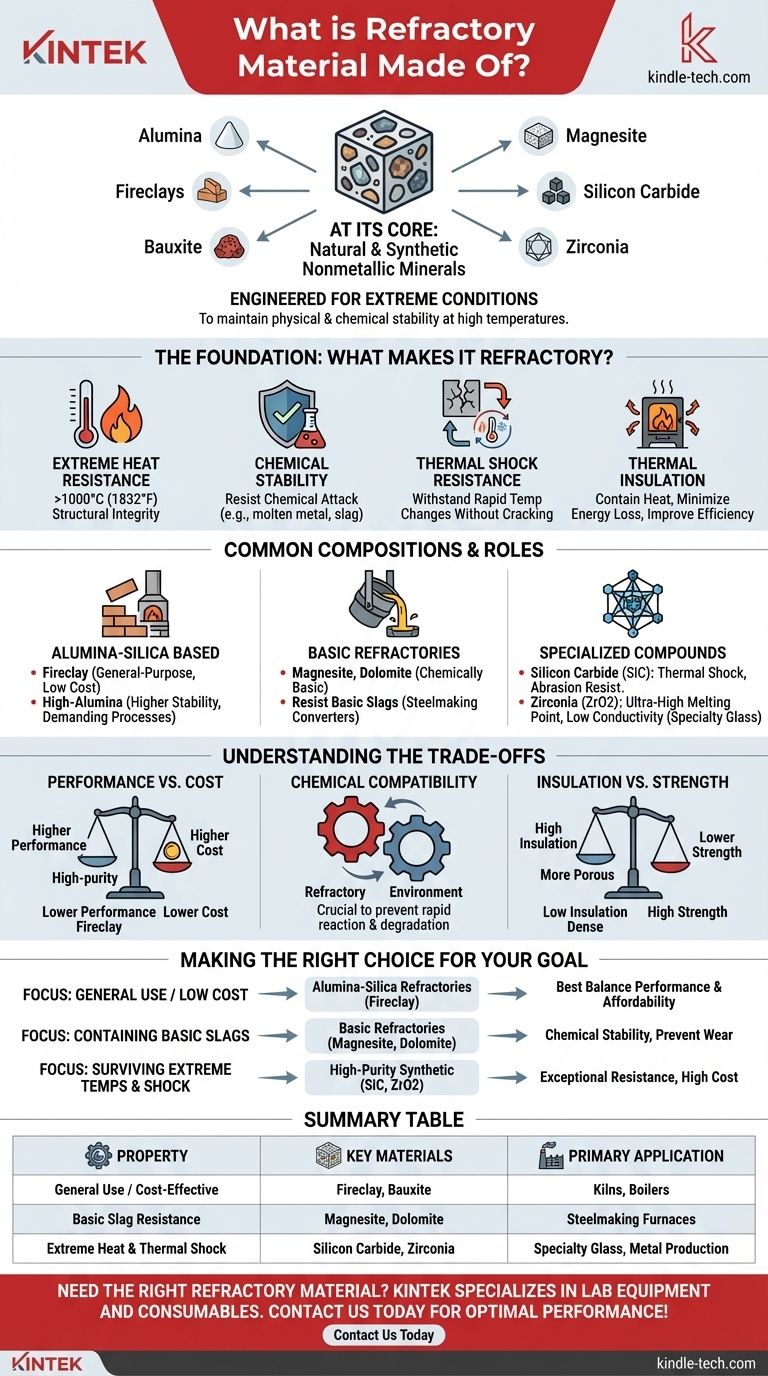

At its core, a refractory material is made from a range of natural and synthetic nonmetallic minerals. These are specifically chosen for their ability to withstand extreme conditions. Key components include compounds and minerals like alumina, fireclays, bauxite, magnesite, silicon carbide, and zirconia.

The specific composition of a refractory is not arbitrary; it is engineered to achieve a single, critical goal: to maintain physical and chemical stability at incredibly high temperatures. The choice of raw materials directly dictates the material's performance, determining its resistance to heat, chemical attack, and thermal shock.

The Foundation: What Makes a Material 'Refractory'?

A material earns the title "refractory" by possessing a specific set of properties. These characteristics are the reason they are indispensable in high-temperature industrial processes like furnaces and kilns.

Extreme Heat Resistance

This is the most fundamental property. Refractory materials have exceptionally high melting points and can maintain their structural integrity at service temperatures often exceeding 1000°C (1832°F).

Chemical Stability

In many industrial applications, refractories are exposed to corrosive liquids and gases, such as molten metal or slag. A key function is to resist chemical attack and avoid reacting with these substances, which prevents both contamination of the product and degradation of the lining.

Thermal Shock Resistance

Industrial processes often involve rapid temperature changes. Refractory materials must be able to withstand these thermal cycles—heating up and cooling down quickly—without cracking or spalling. This property is known as thermal shock resistance.

Thermal Insulation

A primary role of a refractory is to contain heat within a vessel. Good thermal insulation performance ensures that heat remains inside the furnace or reactor, minimizing energy loss and improving overall efficiency. This is why modern refractories can lead to significant energy savings.

Common Refractory Compositions and Their Roles

Refractory materials are typically categorized by their chemical makeup. The choice depends entirely on the specific application's temperature, chemical environment, and mechanical stress.

Alumina-Silica Based

This is the most common and versatile category, derived from minerals like fireclay, bauxite, and pure alumina.

- Fireclay: A cost-effective and widely used material for general-purpose applications like kilns and boilers.

- High-Alumina: By increasing the percentage of alumina, the material's refractoriness and stability under load are significantly improved, making it suitable for more demanding processes.

Basic Refractories

Composed of materials like magnesite and dolomite, these refractories are chemically basic. They are used in environments where they will be in contact with basic slags, such as in steelmaking converters and electric arc furnaces, because they will not react chemically.

Specialized Compounds

For the most extreme environments, specialized synthetic materials are required.

- Silicon Carbide (SiC): Offers exceptional thermal shock resistance, high thermal conductivity, and excellent resistance to abrasion. It is often used in waste incinerators and as kiln furniture.

- Zirconia (ZrO2): Possesses one of the highest melting points of all refractories and exhibits very low thermal conductivity, making it ideal for ultra-high temperature applications like specialty glass and metal production.

Understanding the Trade-offs

Selecting a refractory is a balancing act. There is no single "best" material, only the most appropriate one for a given set of conditions.

Performance vs. Cost

There is a direct correlation between a refractory's performance and its cost. Common fireclays are relatively inexpensive, while high-purity synthetic materials like zirconia are extremely expensive. The selection is always an economic decision weighed against the process requirements.

Chemical Compatibility is Crucial

One of the most common failure modes is selecting a refractory that is chemically incompatible with its environment. For example, using an acidic refractory (like one high in silica) in contact with a basic slag will cause a rapid chemical reaction and swift degradation of the refractory lining.

Insulation vs. Mechanical Strength

Materials that are excellent thermal insulators are often more porous and have lower mechanical strength. Conversely, dense, strong refractories may have higher thermal conductivity. In many furnace designs, a multi-layer lining is used, with a dense, strong hot face backed by a more insulating, weaker layer to optimize for both properties.

Making the Right Choice for Your Goal

Your application's specific demands dictate the ideal refractory composition.

- If your primary focus is general use at a low cost: Alumina-silica refractories, particularly those based on fireclay, provide the best balance of performance and affordability.

- If your primary focus is containing basic slags, as in steelmaking: You must use basic refractories like magnesite or dolomite to ensure chemical stability and prevent rapid wear.

- If your primary focus is surviving extreme temperatures and thermal shock: High-purity synthetic materials like silicon carbide or zirconia are required, even with their associated high cost.

Ultimately, understanding the link between a refractory's composition and its properties is key to ensuring the safety, efficiency, and longevity of any high-temperature process.

Summary Table:

| Property | Key Materials | Primary Application |

|---|---|---|

| General Use / Cost-Effective | Fireclay, Bauxite | Kilns, Boilers |

| Basic Slag Resistance | Magnesite, Dolomite | Steelmaking Furnaces |

| Extreme Heat & Thermal Shock | Silicon Carbide, Zirconia | Specialty Glass, Metal Production |

Need the right refractory material for your high-temperature process? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision. Our experts can help you select the ideal refractory composition to enhance your furnace's efficiency, durability, and safety. Contact us today to discuss your specific requirements and achieve optimal performance!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- What is the best brazing rod for stainless steel? Match the Right Alloy for Maximum Strength & Durability

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- What factors should be considered when selecting an oil-free diaphragm vacuum pump? A Guide to Optimal Performance & Longevity

- What is the role of a magnetic stirrer in silver sulfide rarefaction? Enhance Photocatalytic Efficiency

- How does an automatic PID temperature controller ensure data accuracy? Achieve Precision in Propane Oxidation

- Which material is used for refractory lining in a furnace? Select the Right Lining for Your Process

- What are the primary considerations for selecting Tungsten Carbide (WC) grinding balls? Optimize Your Milling Process

- What is the function of the quartz tube? A Guide to High-Temperature, High-Purity Processing