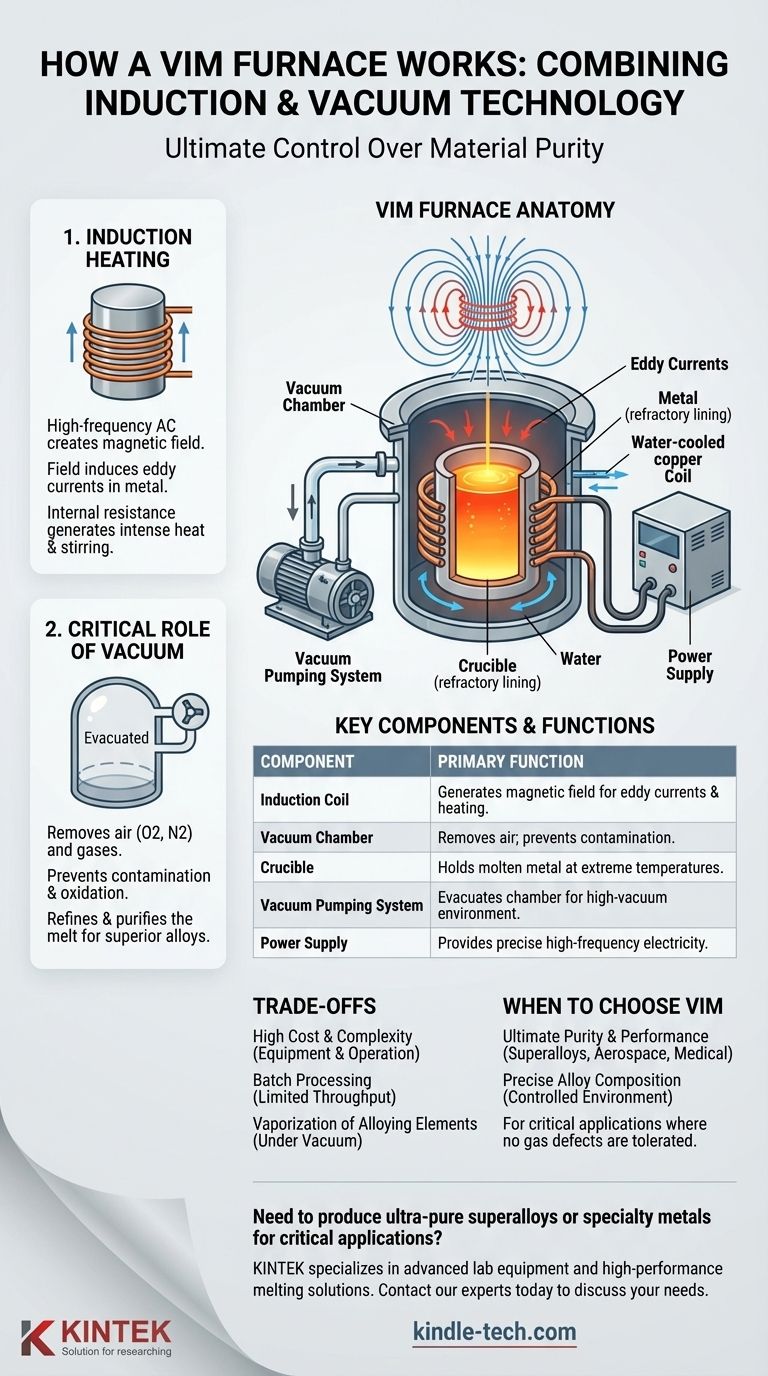

A Vacuum Induction Melting (VIM) furnace works by combining two core technologies: it uses a powerful, water-cooled induction coil to generate a magnetic field that melts conductive metals, and it does this all within a sealed, high-vacuum chamber. The magnetic field induces strong electrical currents directly within the metal, causing it to heat rapidly and liquefy. The vacuum environment is critical, as it removes air and other gases, preventing the molten metal from reacting with oxygen and nitrogen and ensuring an exceptionally clean, high-purity final product.

The fundamental purpose of a VIM furnace is not just to melt metal, but to achieve ultimate control over the material's purity. By eliminating atmospheric contamination, it enables the creation of high-performance superalloys and specialty metals that are impossible to produce in an open-air environment.

The Two Core Principles: Induction and Vacuum

To understand a VIM furnace, you must first understand its two foundational technologies. Each serves a distinct but complementary purpose.

How Induction Heating Works

An induction furnace operates on the principle of electromagnetic induction, functioning much like a transformer.

A high-frequency alternating current is passed through a primary coil made of hollow copper tubing. This coil surrounds a crucible containing the metal to be melted (the charge).

The current in the coil generates a powerful, rapidly fluctuating magnetic field that penetrates the metal charge.

This magnetic field induces strong secondary electrical currents, known as eddy currents, to flow within the metal itself. The metal's natural resistance to these currents generates immense heat, causing it to melt quickly and efficiently.

Critically, the heat is generated directly inside the metal, not by an external flame or heating element. This process also creates a natural stirring action, ensuring the molten bath is homogenous and alloys are mixed uniformly.

The Critical Role of the Vacuum

The vacuum is what separates VIM from standard induction melting and is essential for producing high-quality materials.

The entire process takes place in a sealed steel chamber connected to a high-speed vacuum pumping system. Before heating begins, the system removes almost all the air from the chamber.

This prevents the highly reactive molten metal from coming into contact with atmospheric gases, primarily oxygen and nitrogen. These gases create undesirable impurities (oxides and nitrides) that can compromise the mechanical properties of the final alloy.

The vacuum also helps draw out dissolved gases already present within the raw materials, further refining and purifying the melt.

Anatomy of a VIM Furnace

A VIM furnace integrates several key components to achieve its precise control over the melting process.

The Induction Coil and Crucible

The heart of the furnace is the water-cooled copper coil. Water constantly circulates through the hollow coil to keep it from overheating while it carries the massive electrical current needed for melting.

Inside the coil sits the crucible, a refractory-lined container designed to hold the liquid metal at extreme temperatures.

The Vacuum Chamber and Pumping System

A robust steel chamber encloses the coil and crucible assembly. This chamber is engineered to withstand both high internal temperatures and a powerful external vacuum.

A sophisticated system of vacuum pumps works to evacuate the chamber to a very low pressure before and during the melting cycle.

The Power Supply

A dedicated induction power unit supplies the high-frequency electricity to the coil. The frequency and power level can be precisely adjusted based on the type of metal, the size of the charge, and the stage of the melting process.

Understanding the Trade-offs and Limitations

While VIM technology is superior for purity, it comes with specific considerations that make it unsuitable for every application.

High Cost and Complexity

Integrating a high-power induction system with a high-vacuum system results in a furnace that is significantly more complex and expensive to build, operate, and maintain than a standard air-melt furnace.

Batch Processing and Throughput

VIM furnaces operate in batches. A single batch of material is loaded, the chamber is sealed and evacuated, the material is melted, and then it is poured and cooled before the next batch can begin. This limits throughput compared to continuous melting methods.

Vaporization of Alloying Elements

Operating under a deep vacuum can cause certain alloying elements with high vapor pressure (such as manganese, chromium, or copper) to "boil off" from the molten bath. This requires extremely precise control over temperature and pressure to ensure the final alloy meets its exact chemical specification.

When to Choose VIM Technology

The decision to use a VIM furnace is driven entirely by the required quality and performance of the end material.

- If your primary focus is ultimate purity and performance: VIM is the definitive choice for producing superalloys, medical implants, and aerospace components where freedom from gas-related defects is non-negotiable.

- If your primary focus is precise alloy composition: The controlled environment and inductive stirring of a VIM furnace provide unparalleled control over the final chemical makeup of an alloy.

- If your primary focus is high-volume, general-purpose melting: A standard air-melt induction furnace or a continuous channel furnace will be far more cost-effective for applications where minor atmospheric contamination is acceptable.

Ultimately, understanding the VIM process empowers you to select the precise melting technology required to meet the most demanding material specifications.

Summary Table:

| Key Component | Primary Function |

|---|---|

| Induction Coil | Generates a magnetic field to induce eddy currents and heat the metal directly. |

| Vacuum Chamber | Removes air to prevent contamination from oxygen and nitrogen. |

| Crucible | Holds the molten metal charge at extreme temperatures. |

| Vacuum Pumping System | Evacuates the chamber to create the necessary high-vacuum environment. |

| Power Supply | Provides precise, high-frequency electricity to control the melting process. |

Need to produce ultra-pure superalloys or specialty metals for aerospace, medical, or high-tech applications?

KINTEK specializes in advanced lab equipment, including high-performance melting solutions. Our expertise can help you select the right furnace technology to achieve the ultimate control over material purity and composition that your critical projects demand.

Contact our experts today to discuss how our solutions can meet your specific laboratory melting needs.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the role of a High Vacuum Induction Melting Furnace in preparing reactive alloys? Precision for Fe-Cr-Al Alloys

- What are the disadvantages of inductive heating? High Cost and Material Limitations Explained

- What metals can be melted with induction? From Steel to Gold, Discover the Versatility

- What is the temperature of an induction furnace? Understanding Capabilities from 1250°C to 2000°C+

- How hot can an induction heater get? Achieve up to 3000°C for precise industrial heating

- What is the primary product manufactured by an electric induction furnace? It's a State of Matter, Not a Final Product

- What is the objective of induction furnace? Achieve Clean, Precise Metal Melting with High Purity

- What are the factors affecting induction heating? Master the Key Variables for Precise Thermal Control